An automatic furniture assembly line that can be polished on multiple sides

A technology of automatic assembly and production line, which is applied in the direction of grinding drive device, grinding feed motion, grinding machine parts, etc. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

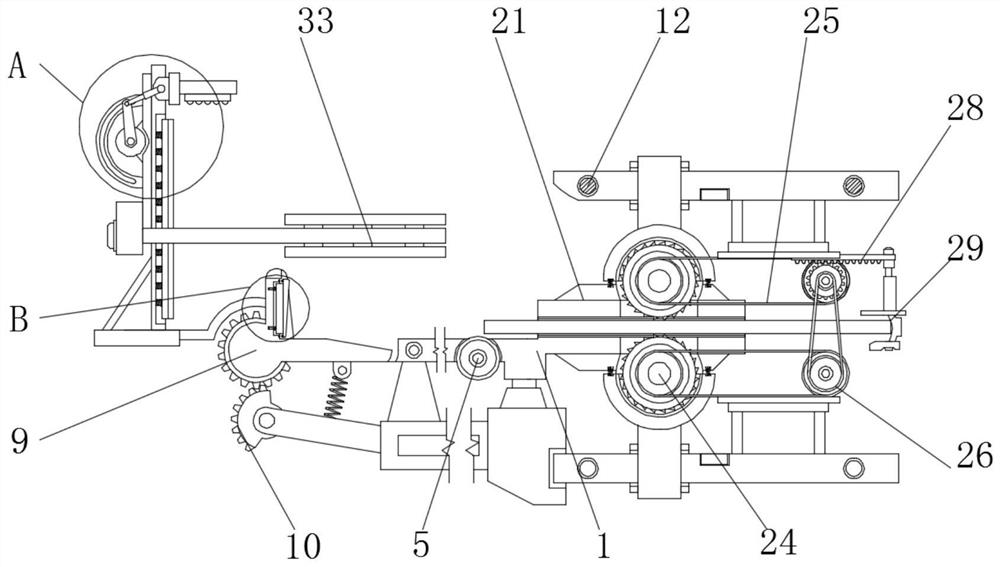

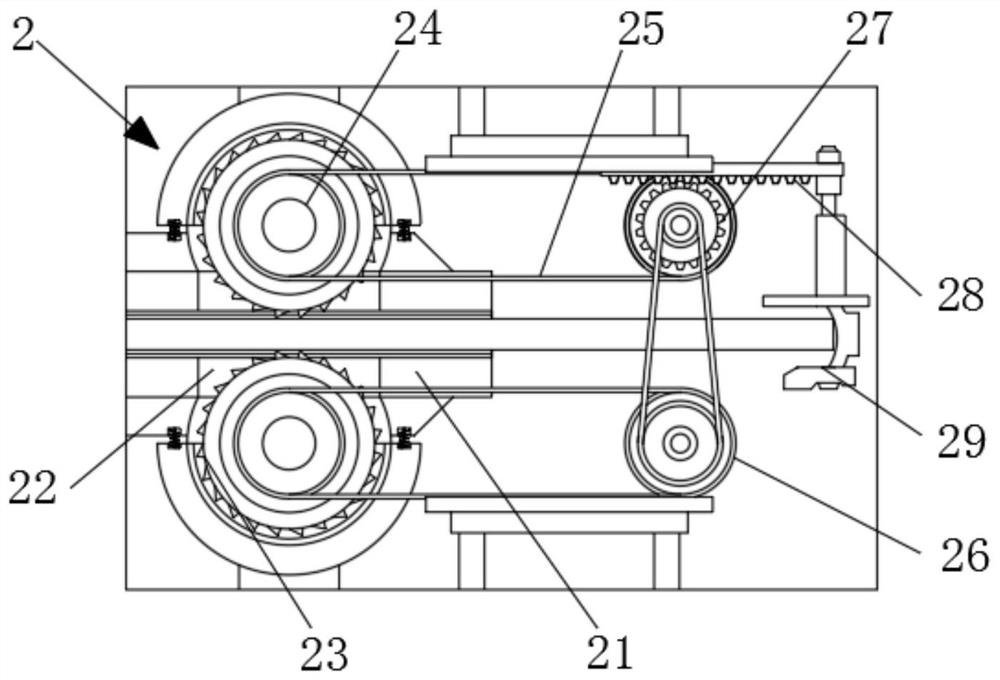

Embodiment 1

[0029] see figure 2 , an automatic furniture assembly production line that can be polished on multiple sides, comprising a main body 1, the main body 1 includes a double-sided grinding mechanism 2, the double-sided grinding mechanism 2 is provided with a two-way placement table 21, and the inside of the two-way placement table 21 An opening cavity 22 is provided, and a cylindrical grinding roller 23 is placed inside the opening cavity 22. A first pulley 24 is sleeved at the center of one end of the cylindrical grinding roller 23, and a transmission belt 25 is sleeved outside the first pulley 24. The other end of the transmission belt 25 away from the first pulley 24 is movably connected with a second pulley 26, and the right side of the second pulley 26 is movably connected with a driving gear 27, and the external meshing of the driving gear 27 is connected with a sliding tooth plate 28, the sliding tooth The lower end of the plate 29 is movably connected with a pushing splin...

Embodiment 2

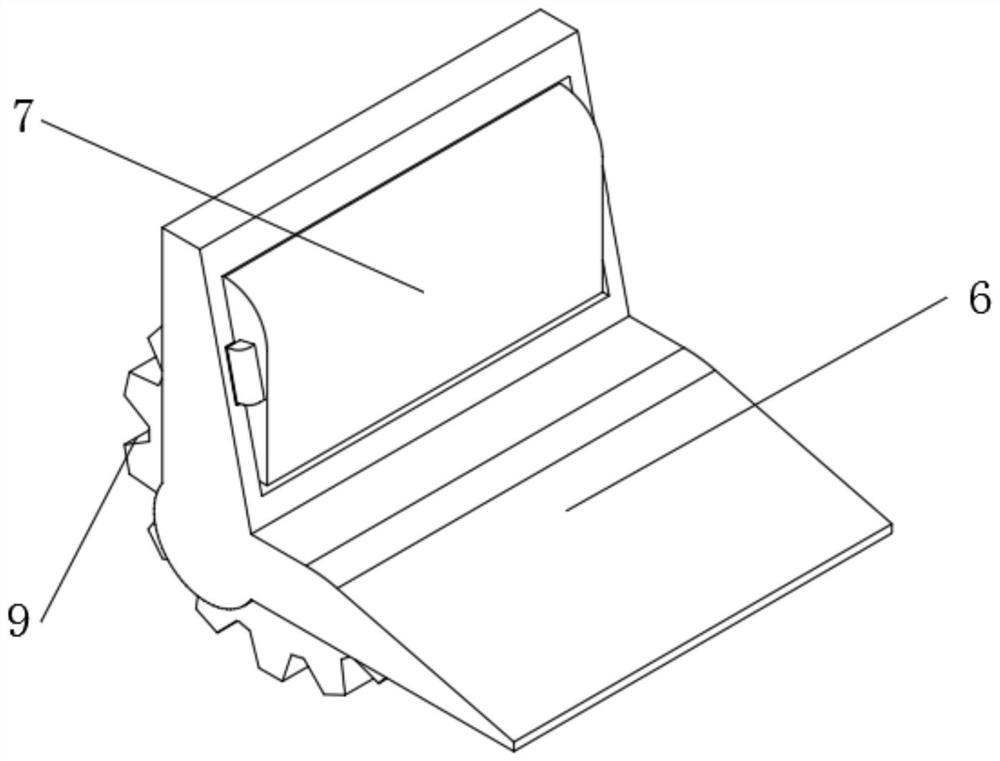

[0032] see Figure 4 and Figure 5, an automatic furniture assembly production line capable of multi-face polishing, comprising a main body 1, the main body 1 further includes a collection and stacking mechanism 3, the collection and stacking mechanism 3 is provided with a placement plate 31 inside, The outside of the placing plate 31 is socketed with a positioning frame 32, and the two ends of the positioning frame 32 are movably connected to the limiting plate 33, and the limiting plate 33 is provided with two groups of in and out pulleys 34 near the side of the placing plate 31, and the outside of the positioning frame 32 Sliding frame 35 is sleeved, and the external activity of sliding frame 35 presses movable frame 36, and the external movable connection of sliding frame 35 is connected with telescopic pull rod 37, and the external movable connection of telescopic pull rod 37 is connected with turntable 38, and one end of telescopic pull rod 37 is movably socketed on Ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com