Liquid phase impregnation tool for preparing C/C composite material and charging method

A technology of liquid phase impregnation and composite materials, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of high impregnation dosage, small furnace loading, and adhesion, etc., to improve the production capacity of a single furnace, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

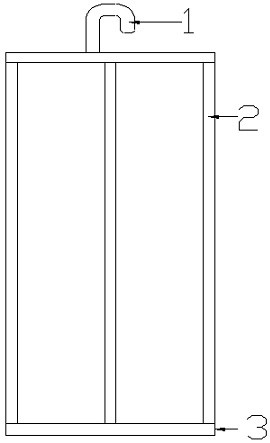

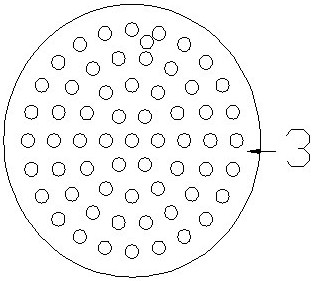

[0034] A process for preparing the liquid immersion unit C / C composites, apertured rack chassis, using spaced stainless steel shim stock stacked. Impregnating furnace effective size of Φ800mm × 1200mm, stainless steel cylinder is Φ780mm × 1150mm, design and processing a stainless steel rack Φ760mm × 1120mm, the plurality of 1.5mm thick stainless steel shims.

[0035] 1) at the bottom of the first rack and orderly placed dense layer blank, is not more than the bottom edge of the rack;

[0036] 2) The size of the blank, each blank is placed on a stainless steel spacer 2 to 4, and then placing the upper blank, the number and size to ensure that the gasket is placed on upper smooth blank, each blank are sequentially stacked according to the way the gasket + load blank;

[0037] 3) The Bahrain preg blank is impregnated into the barrel lifting frame and furnace load pressure impregnation, impregnation start of work;

[0038] 4) impregnating finished baked, cooled discharge to be blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com