3D effect UV printing intelligent plate capable of being Interconnected and preparation method of 3D effect UV printing intelligent plate

A 3D effect and inkjet technology, which is applied in the directions of reproduction/marking methods, chemical instruments and methods, and post-processing of printing, etc., which can solve the difficulty in realizing personalized customization, 3D effect patterns and interconnection, and intelligent plates cannot realize personalized customization. , stagnant market promotion and other issues, to achieve the effect of promoting popularization and development, reasonable and efficient production technology, and simplifying wiring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

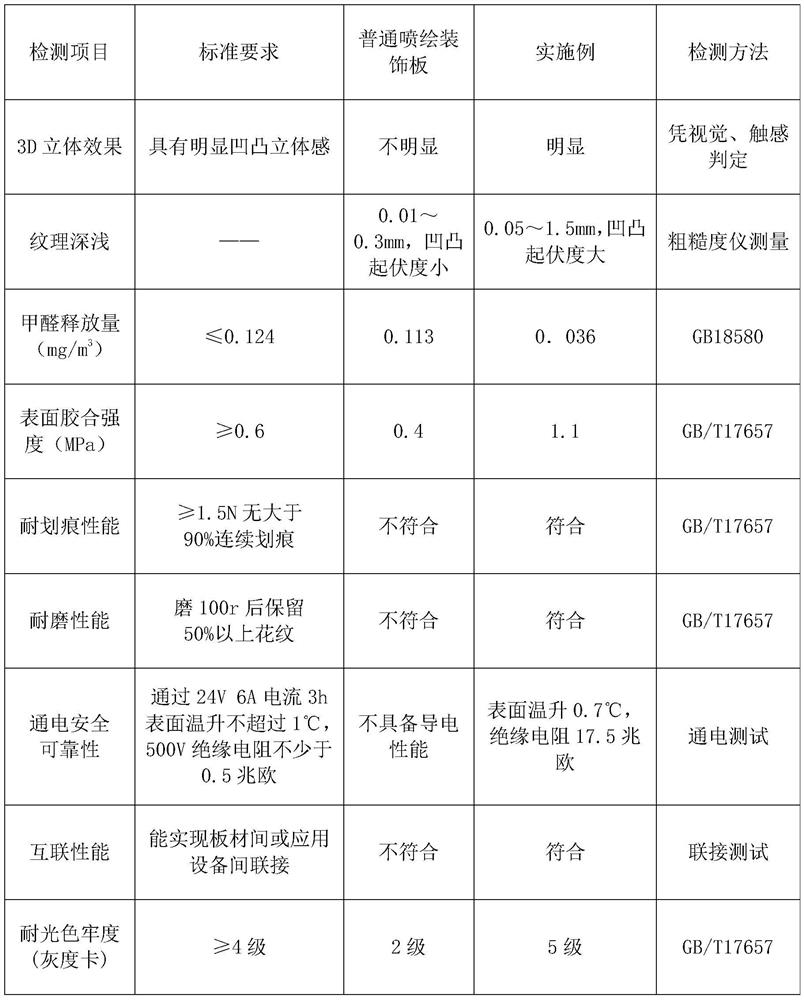

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the scope of protection claimed by the present invention is not limited to the embodiments.

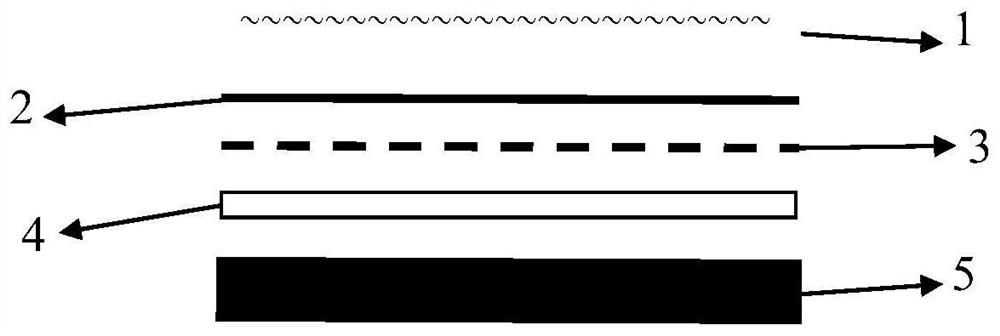

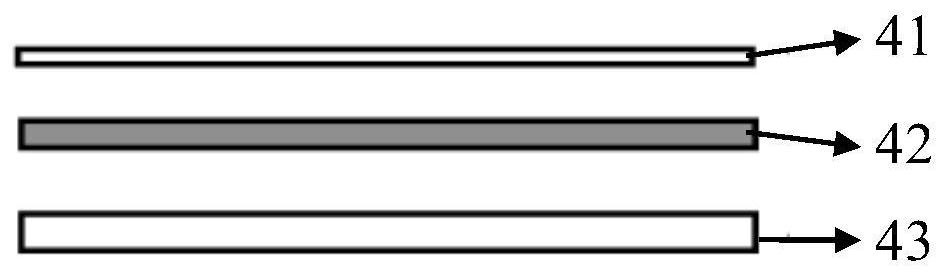

[0042] The preparation method of 18mm interconnectable synchronous anti-grain 3D effect UV inkjet integrated intelligent particle board with built-in circuit is as follows:

[0043] (1) The appearance quality and physical and chemical properties meet the standard requirements of particle board, and the formaldehyde emission is 0.03mg / m 3 The 9mm particleboard passes through the trough of the CNC machining center to make the wire groove. The wire groove width is 12mm and the depth is 0.4mm. The groove end is provided with a groove with a width of 50mm and a depth of 30mm and a height of 5mm for pre-embedded connectors;

[0044] (2) Lay copper strips ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com