Hydraulic clay gun differential control loop and control method

A control loop, mud gun technology, applied in blast furnace parts, furnace, blast furnace details, etc., can solve the problems of increased equipment and burner nozzle failures, waste of energy, slow mud gun rotation speed, etc., to increase efficiency and success rate , the effect of reducing the power configuration and increasing the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

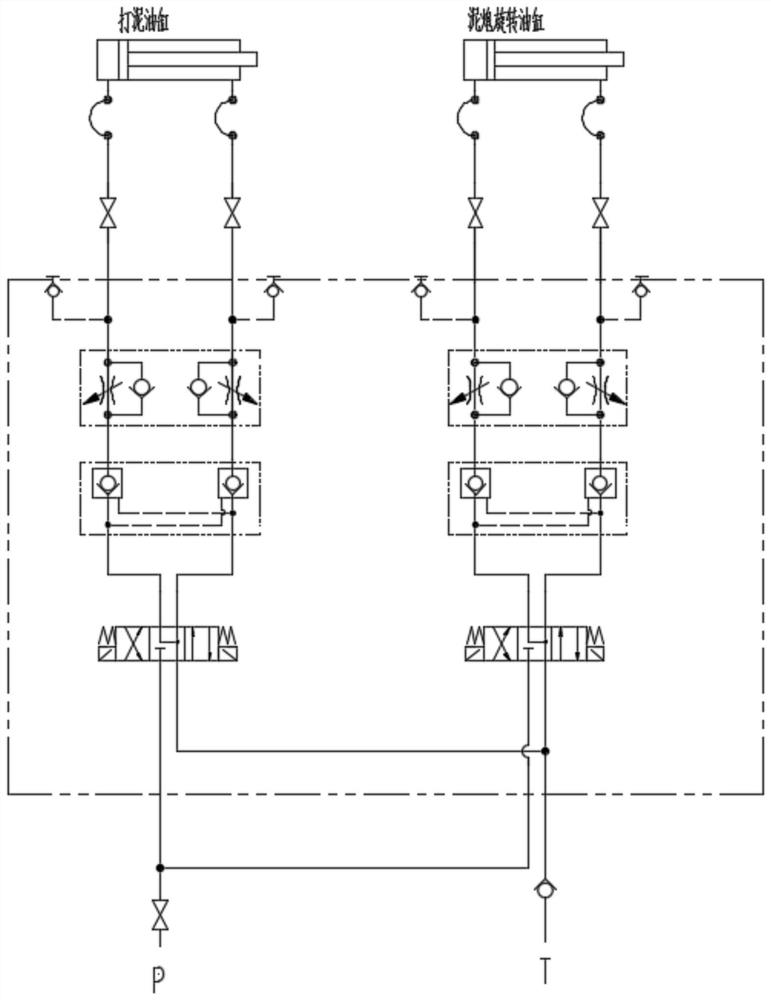

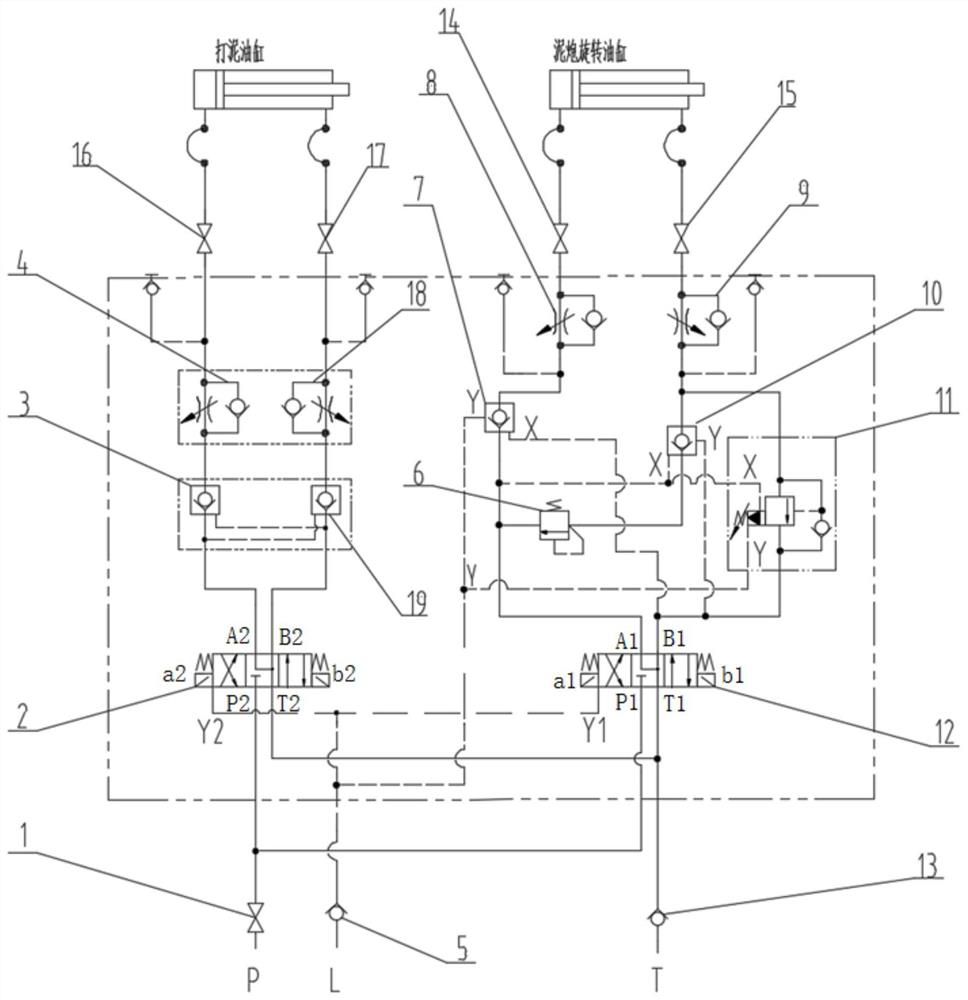

[0035] see figure 2 As shown, the present invention provides a hydraulic mud gun differential control circuit, including a first reversing valve 12, a hydraulic control check valve, a throttle valve, an overflow valve, a sequence valve, a ball valve and a mud gun rotary cylinder;

[0036] The oil inlet P1 of the first reversing valve 12 communicates with the oil supply pipeline P through the oil passage, and the oil return port T1 of the first reversing valve 12 communicates with the oil return pipeline T through the oil passage. The oil drain port Y1 of a reversing valve 12 communicates with the oil drain line L through the oil passage; the first check valve 13 is installed on the oil return line T, and the second check valve 5 is installed on the oil drain line L;

[0037] The hydraulic oil output by the first output oil port A1 of the first reversing valve 12 is divided into two circuits: one hydraulic oil passes through the first hydraulic control check valve 7, the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com