Care control method of clothes treatment equipment

A technology of clothes processing equipment and control methods, which is applied to the control devices of washing machines, washing devices, textiles and papermaking, etc., which can solve the problems of wasting energy and time, large damage to clothes, and unsuitability of high-end clothes, and reduce hardware requirements and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

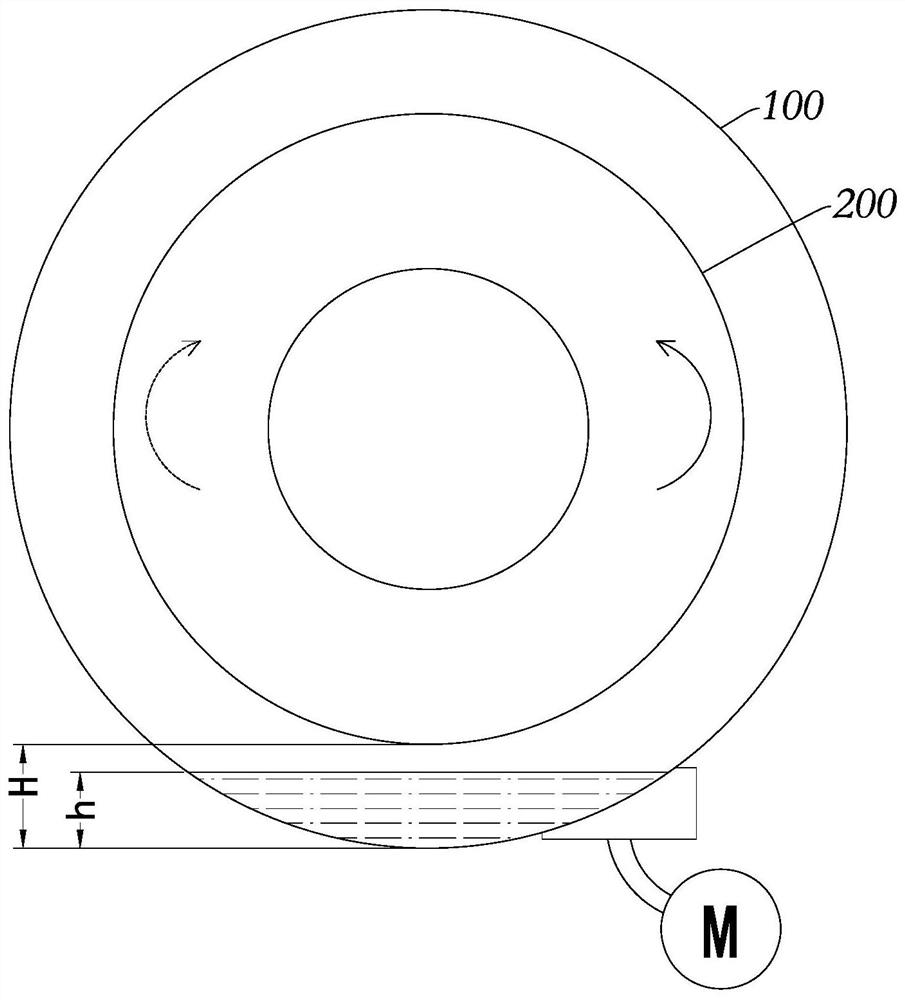

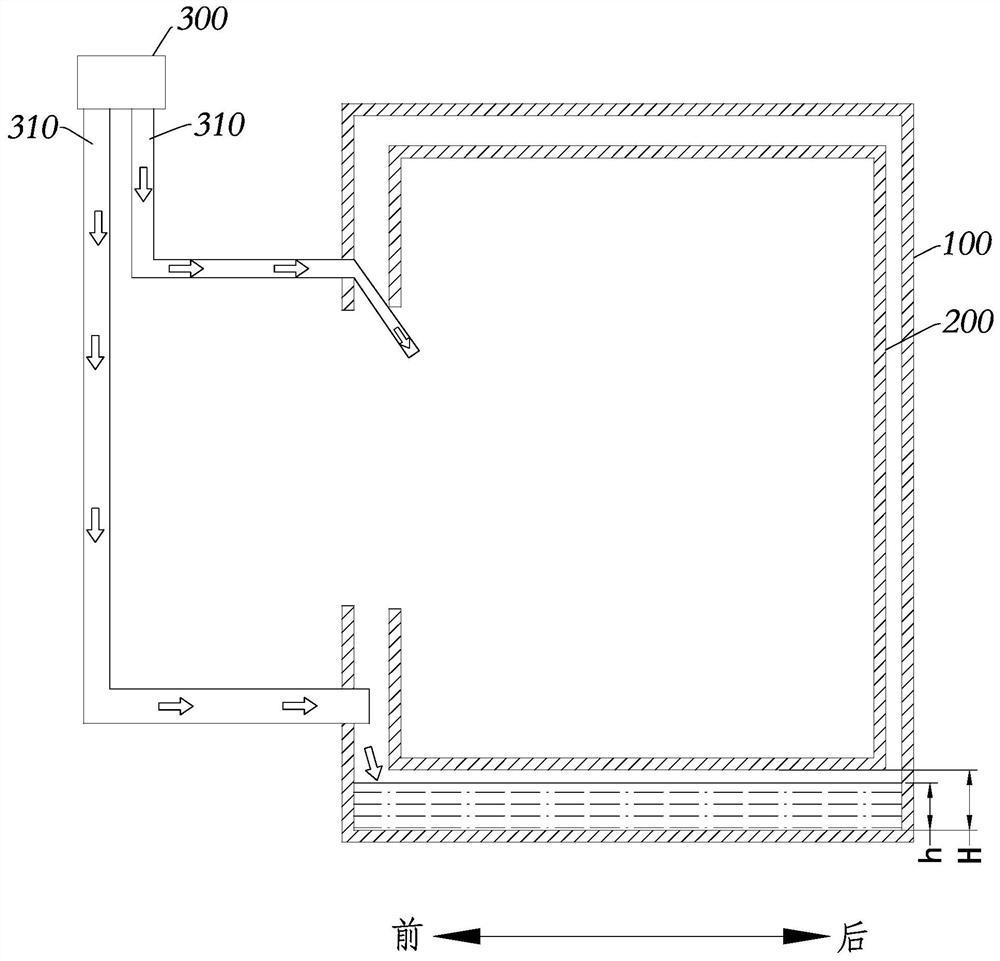

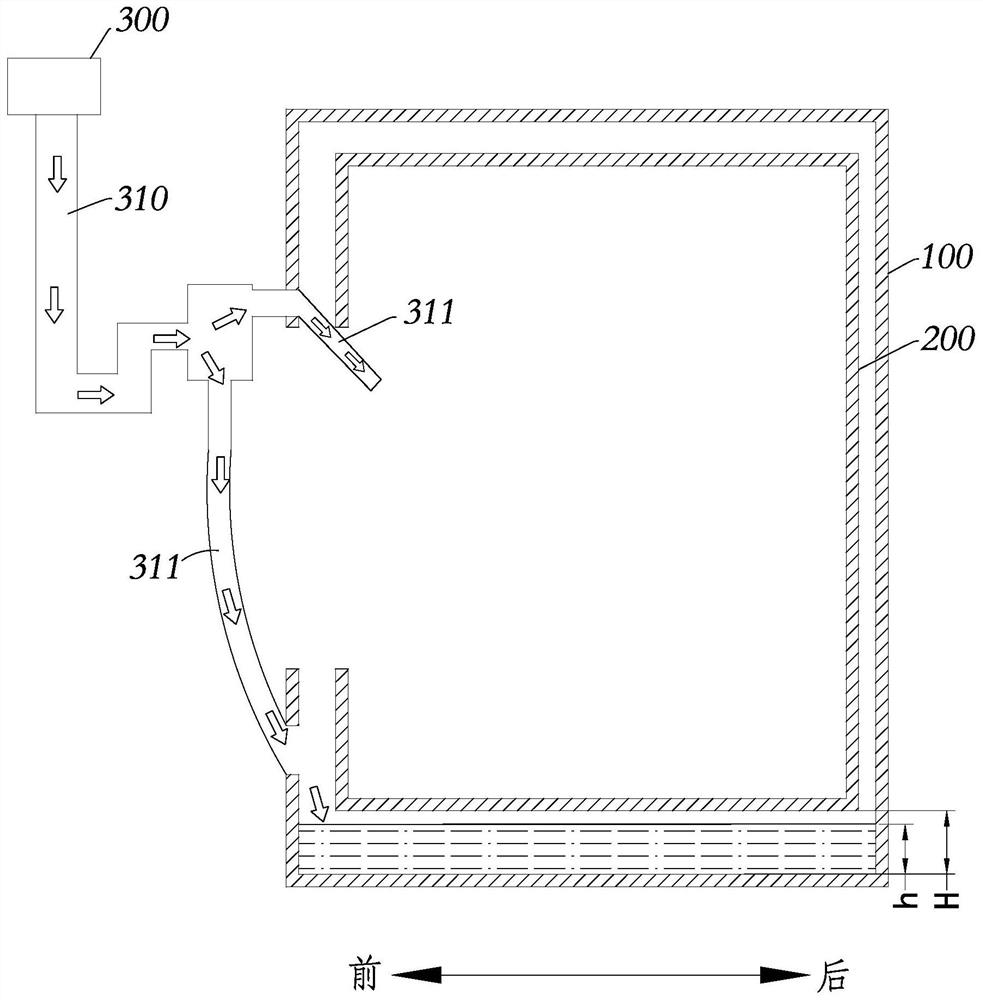

[0044]The laundry treatment equipment care control method proposed by the present invention, the laundry treatment equipment includes a water inlet component, a bucket and a washing bucket arranged in the bucket and communicated with the bucket, characterized in that the control The method includes: a water inlet step, wherein the water inlet assembly feeds water between the tub and the washing tub, the water level in the tub is h, and the radial distance between the tub and the tub H, h≤H; care step, in the water inlet step or after the water inlet step, the rotation of the washing tub generates an airflow, thereby driving water vapor into the washing tub for clothing care. The care control method proposed by the present invention can care for the clothes on the premise that the clothes are not wet, and the clothes treatment equipment does not need additional devices such as heaters and spray devices, which reduces the hardware requirements and costs for clothes care; and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com