Preparation method of washable 5A-grade antibacterial and antiviral graphene fiber and fiber product

A graphene fiber, anti-virus technology, applied in fiber processing, biochemical fiber processing, textiles and papermaking, etc., can solve the problems of poor graphene dispersing ability, difficulty in graphene finishing, poor effect, etc., and achieves a simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

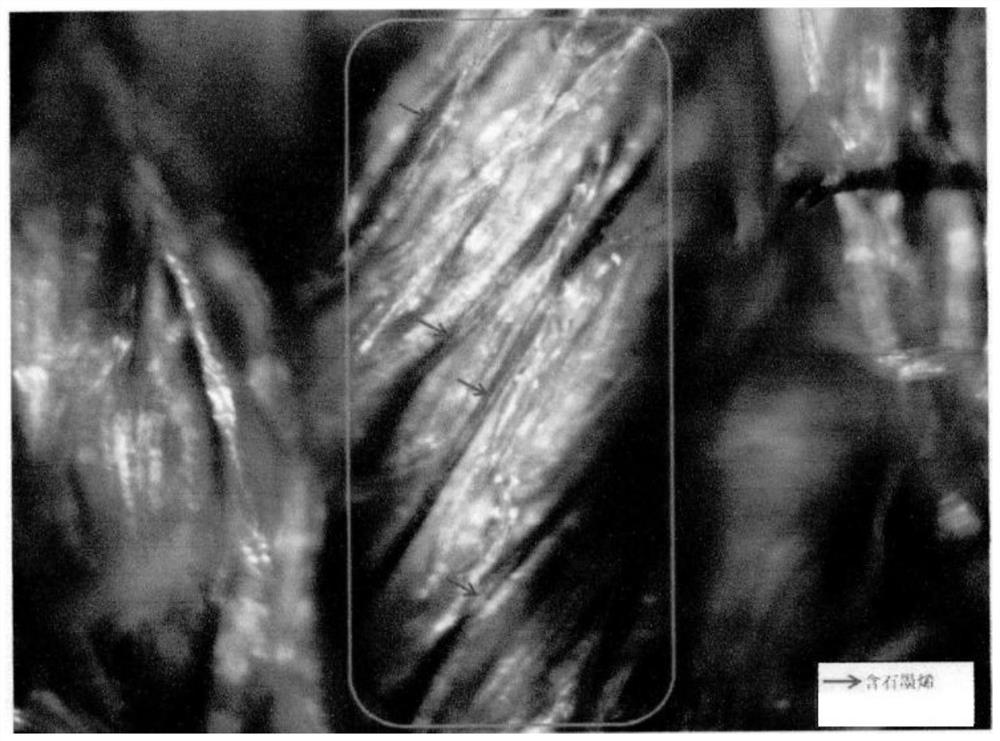

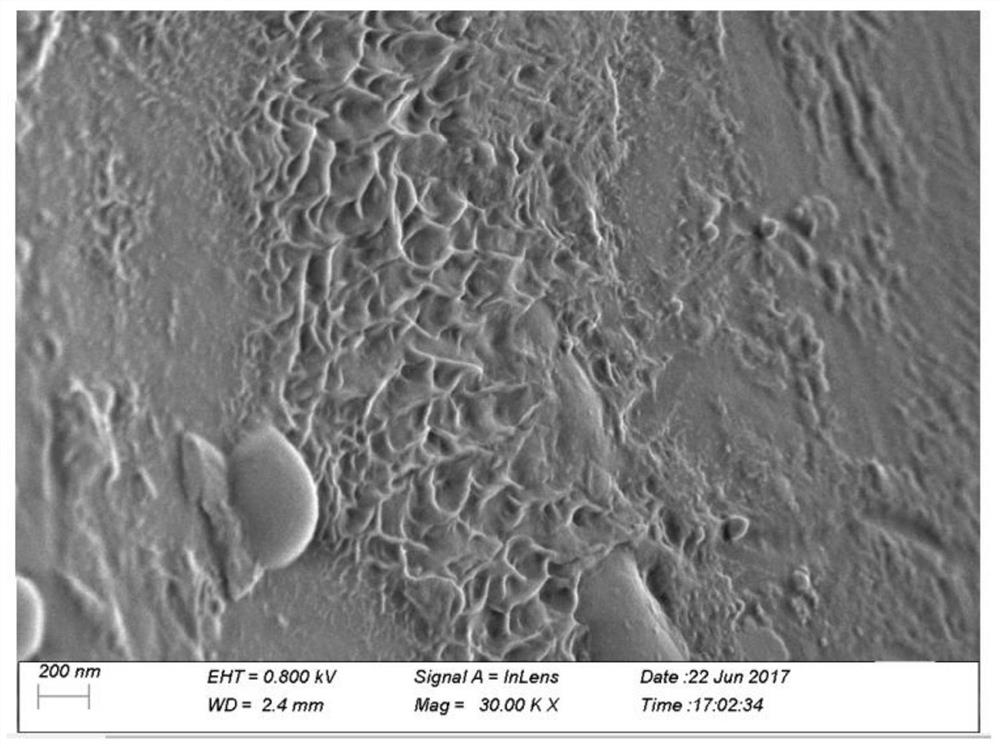

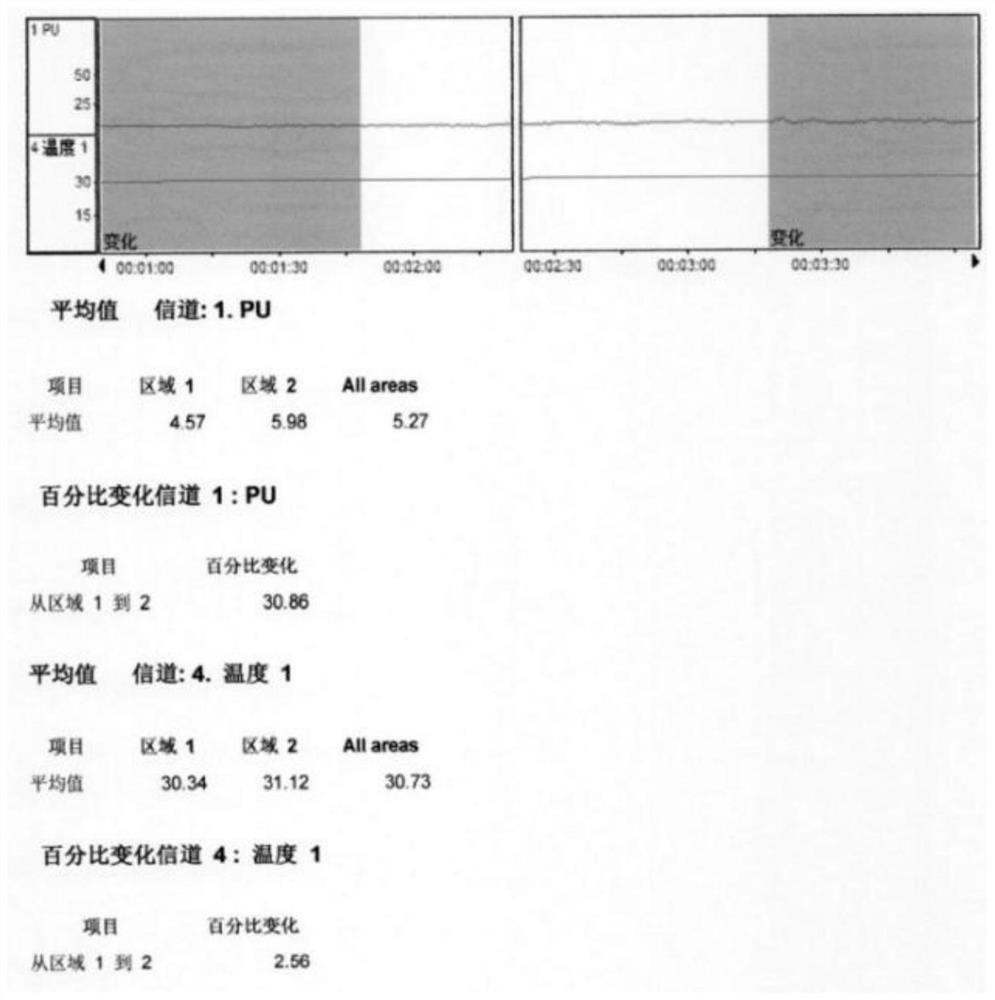

Image

Examples

Embodiment 1

[0033] 1 Preparation method

[0034] This embodiment provides a method for preparing water-resistant 5A antibacterial and antiviral graphene fibers, which is prepared by a dipping process, specifically including the following steps:

[0035] S1: Antibacterial and antiviral treatment is carried out on the raw fiber or fiber fabric to obtain antibacterial and antiviral fiber or fiber fabric, specifically including:

[0036] Step (1): The raw material fibers or fiber fabrics are boiled and bleached in the pretreatment working solution to produce reactive free radicals. Specifically, take 20g of raw material fibers or fiber fabrics and place them in a 300cc jar In the middle, the cylinder cup is equipped with a pretreatment working solution: 50% hydrogen peroxide 4g / L, 100% sodium hydroxide 4g / L, scouring agent 2g / L, and the yarn is reacted at 100°C at a bath ratio of 1:10 60min, obtain the raw material fiber or fiber fabric with better capillary effect, and described refining ag...

Embodiment 2

[0070] This embodiment provides a method for preparing water-resistant 5A antibacterial and antiviral graphene fibers, which is prepared by a padding process, and specifically includes the following steps:

[0071] S1: Antibacterial and antiviral treatment is carried out on the raw fiber or fiber fabric to obtain antibacterial and antiviral fiber or fiber fabric, specifically including:

[0072] Step (1): The raw material fibers or fiber fabrics are boiled and bleached in the pretreatment working solution to produce reactive free radicals. Specifically, take 20g of raw material fibers or fiber fabrics and place them in a 300cc jar In the middle, the cylinder cup is equipped with a pretreatment working solution: 50% hydrogen peroxide 4g / L, 100% sodium hydroxide 4g / L, scouring agent 2g / L, and the yarn is reacted at 100°C at a bath ratio of 1:10 60min, obtain the raw material fiber or fiber fabric with better capillary effect, and described refining agent is selected from prior a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com