A large bypass ratio turbofan engine core cabin ventilation structure and ventilation method

A turbofan engine with a large bypass ratio technology, which is applied in the direction of engine components, engine cooling, sustainable transportation, etc., can solve the problem that the number of bleed air openings on the wall cannot be too large, cannot be reached, and the circumferential cooling of the core cabin is not enough Uniformity and other issues to achieve good flow heat transfer effect in the cabin and good exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

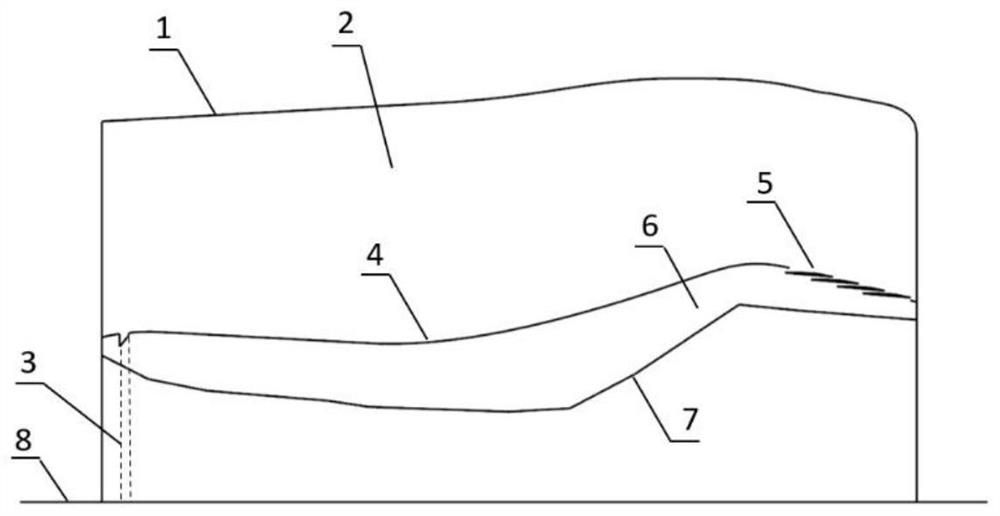

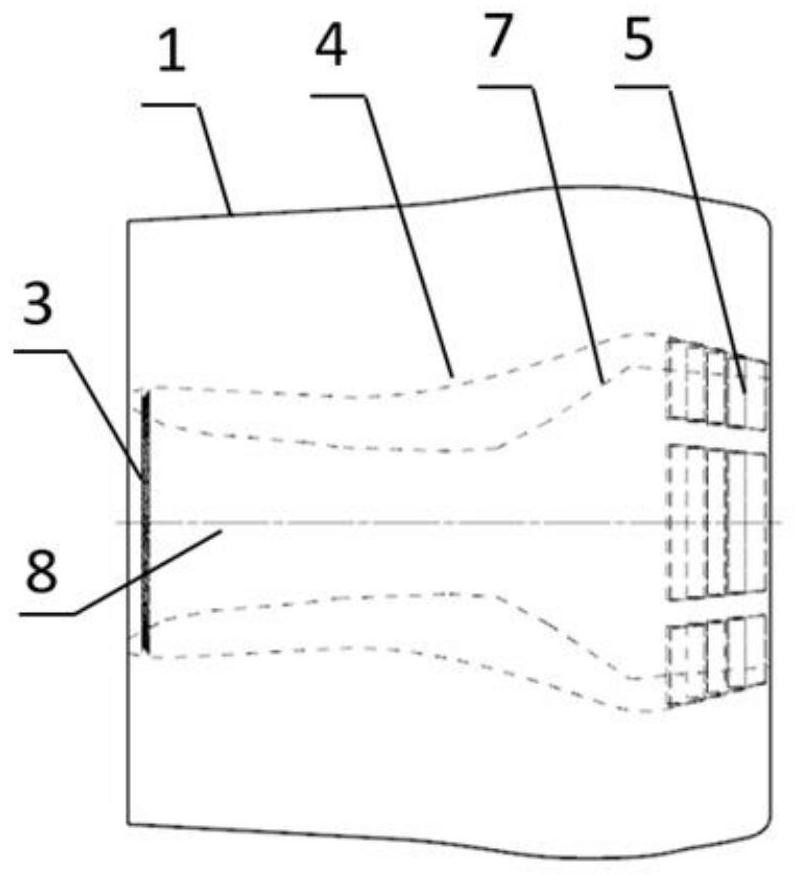

[0037] see Figure 1-Figure 10 , the present embodiment provides a high bypass ratio turbofan engine core cabin ventilation structure, including:

[0038] Outer bypass duct wall 1, core engine room wall 4, core engine casing 7, the outer bypass channel 2 is formed between the outer bypass wall surface 1 and the core engine room wall surface 4, and the core engine room wall 4 and the core engine casing 7 constitute the core cabin 6;

[0039] Among them, an air inlet annular cavity 3 is provided inside and upstream of the core engine room. The air intake annular cavity 3 is used to connect the external flow channel 2 and the core engine room 6, and is also provided on the wall surface 4 of the core engine room and at the rear position. An exhaust grill 5 is provided, and the exhaust grill 5 is used to discharge the cooling gas inside the core nacelle 6 into the bypass flow channel 2 .

[0040] Specifically, in this embodiment, the interior of the air intake annular cavity 3 is...

Embodiment 2

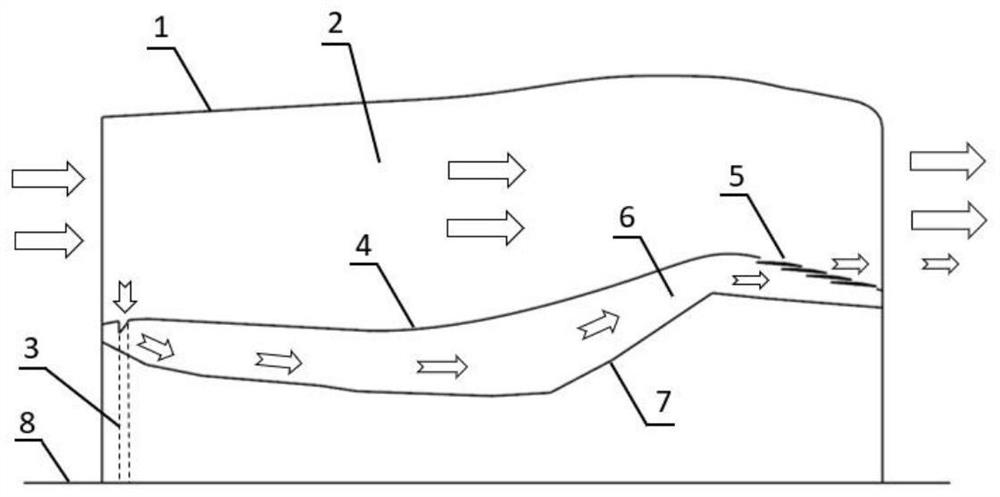

[0043] On the basis of Embodiment 1, the present embodiment provides a ventilation method for the core cabin of a turbofan engine with a large bypass ratio based on a ventilation structure for a core cabin of a turbofan engine with a large bypass ratio provided in Embodiment 1, which specifically includes:

[0044] Step 1: Using the stamping effect, the external airflow in the external runner 2 flows into the cavity of the air intake annular cavity 3 connected to the core nacelle wall 4 through the air intake holes 9 on the core nacelle wall 4;

[0045] Step 2: After the cooling air enters the inside of the air inlet annular cavity 3, it first flows in the circumferential direction, and then from the exhaust holes 11 on the end face 10 of the annular cavity of the air intake annular cavity 3, it is uniformly discharged into the circumferential direction. In the core cabin 6; because the annular cavity end face 10 of the intake annular cavity 3 has an inclined angle, the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com