Humidifying device with self-adaptive adjusting function for textile workshop

An adaptive adjustment and humidification device technology, applied in the field of textile workshops, can solve the problems of water mist content reduction and breeding, and achieve the effects of reducing labor, ensuring quality, and better humidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

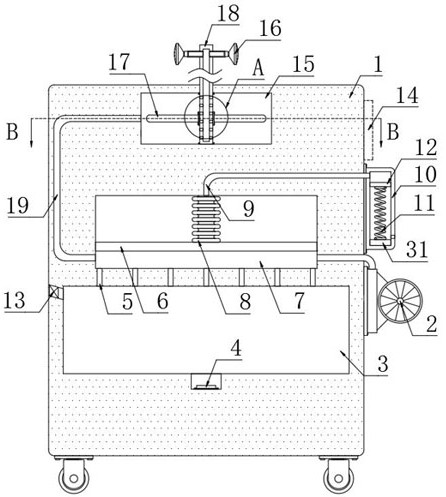

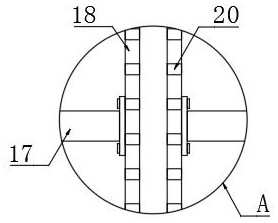

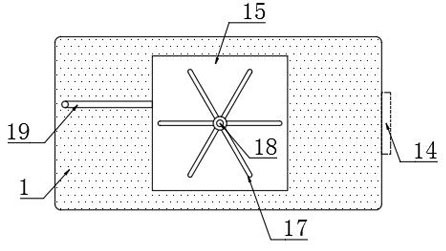

[0030] refer to Figure 1-3 , a humidifying device with an adaptive adjustment function for a textile workshop, comprising a housing 1, an adjustment chamber 7 is arranged in the housing 1, a horizontal plate 6 is arranged in the adjustment chamber 7, and the horizontal plate 6 is made of iron material, The horizontal plate 6 is slidably connected with the inner wall of the adjustment cavity 7, and the right side of the housing 1 is provided with a rectangular box 10, and the rectangular box 10 is provided with an adjustment mechanism, and the adjustment mechanism includes an iron block 12 arranged in the rectangular box 10, and the iron block 12 It is slidingly connected with the inner wall of the rectangular box 10. The inner bottom of the rectangular box 10 is provided with an electromagnet 31. After the electromagnet 31 is energized, it attracts the opposite sex with the adjacent surface of the iron block 12, and the electromagnet 31 passes through the adjacent surface of t...

Embodiment 2

[0044] refer to Figure 4-7 The difference between this embodiment and Embodiment 1 is that a reciprocating cavity 27 is provided in the housing 1, the reciprocating cavity 27 is located below the rotating cavity 15, and the lower end of the standpipe 18 extends into the reciprocating cavity 27 and is fixedly connected with a cam 28, the reciprocating chamber 27 is provided with a piston 29, the piston 29 is slidingly connected with the inner wall of the reciprocating chamber 27, the right side of the piston 29 is elastically connected with the right inner wall of the reciprocating chamber 27 through the second spring 30, and the reciprocating chamber 27 is located at the side of the piston 29 The left space communicates with the outside world through the second port;

[0045] Wherein, the housing 1 is provided with an adsorption cavity 21, the inner bottom of the adsorption cavity 21 is an arc surface, the bottom space of the adsorption cavity 21 communicates with the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com