GaN-based enhanced vertical HEMT device and preparation method thereof

An enhanced device technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of difficulty in making high-performance GaN vertical devices, low Mg activation rate, and large etching damage, etc., to reduce source Electrode on-resistance, process compatibility, and the effect of increasing the drain current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

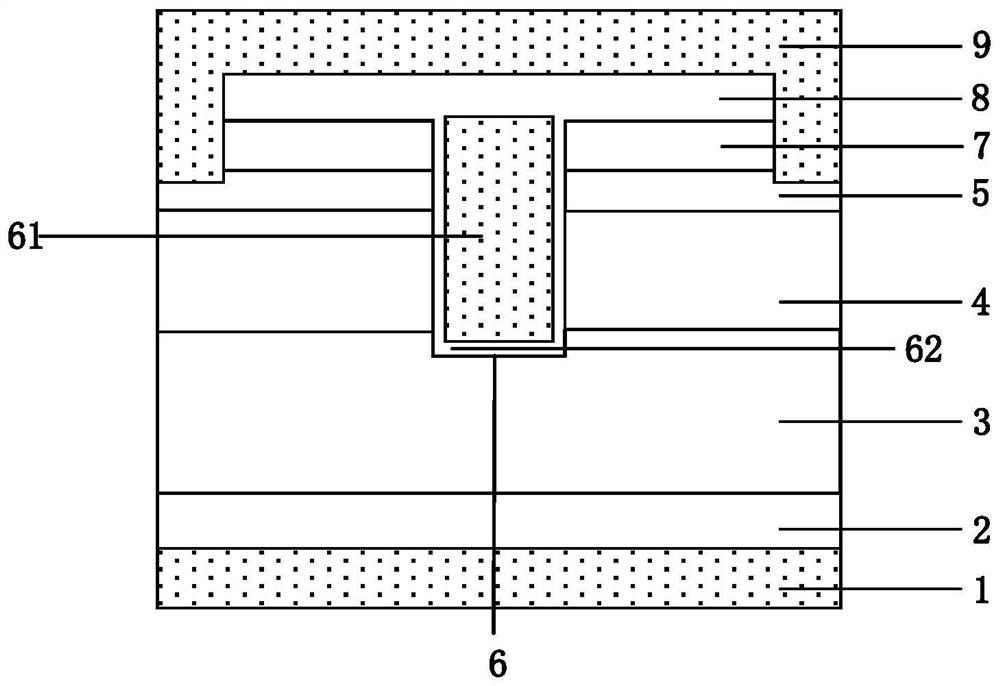

[0032] Such as figure 1 As shown, a GaN-based enhanced vertical HEMT device provided by the present invention includes: a drain 1, a substrate 2, a drift region 3, a vertical channel barrier layer 4, a channel layer 5, a groove gate 6, and a barrier layer 7 , a passivation layer 8 and a source 9, the trench gate 6 includes a trench gate metal 61 and a trench gate dielectric 62, the trench gate dielectric 62 surrounds the trench gate metal, the trench gate dielectric 62 is connected to the passivation layer 8, the drain 1, the liner The bottom 2, the drift region 3, and the vertical channel barrier layer 4 are in contact with each other from bottom to top, and the trench gate 6 is a trench gate, starting from the center of the barrier layer 7, and the groove range is from top to bottom from the barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com