Enhanced GaN-based high electron mobility transistor and preparation method thereof

A high electron mobility, transistor technology, applied in semiconductor/solid state device manufacturing, circuits, electrical components, etc., can solve the problems affecting the performance of HEMT devices, existing off-state leakage current, reducing device performance, etc., to reduce the off-state Effect of leakage current, reduction of off-state leakage current, effect of large forward gate voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Preparation Method of Enhanced GaN-Based High Electron Mobility Transistor

[0046] The first step is to clean the material.

[0047]First, put the sample into the mixture of concentrated sulfuric acid and hydrogen peroxide (concentrated sulfuric acid:hydrogen peroxide=7:3) and soak for 10 minutes. Then put the sample into the diluted ammonia (20%) and hydrogen peroxide mixture (diluted ammonia:hydrogen peroxide=6:1), heat in a water bath for 10 minutes, and set the temperature of the water bath to 85°C. Then put the sample into the aqueous solution of KOH: hydrogen peroxide = 1:2 and soak for 10 minutes, and finally wash it with deionized water. Cleaning the sample with the above-mentioned series of acid and alkali solutions can effectively remove oxides on the surface of the sample, as well as compounds and impurities that are poorly soluble in acetone. Afterwards, the sample is subjected to a traditional cleaning step. First, the sample is placed in aceto...

Embodiment 2

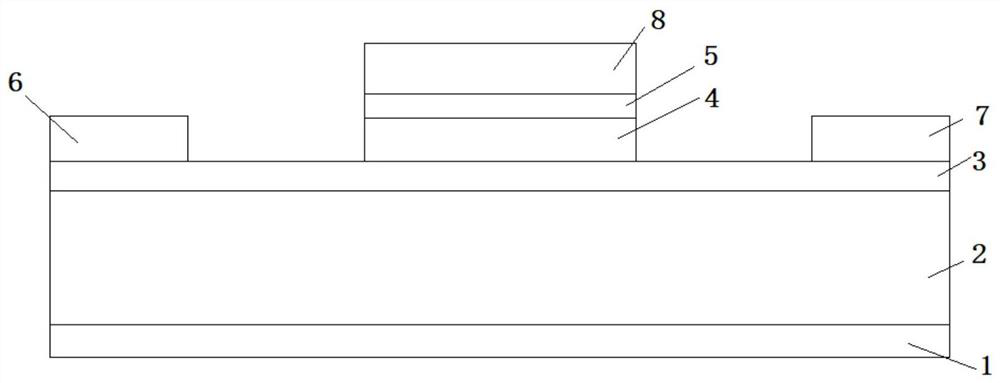

[0068] like figure 1 and Figure 5 As shown, the enhancement mode GaN-based high electron mobility transistor, its structure includes from bottom to top:

[0069] A sapphire substrate layer 1;

[0070] A GaN buffer layer 2, unintentionally doped, with a thickness of 2 μm;

[0071] An AlGaN barrier layer 3 with an Al composition of 0.25 and a thickness of 20 nm;

[0072] An annular p-GaN layer 4 with a Mg doping concentration of 5*10 19 cm -3 , with a thickness of 50nm;

[0073] a ring Ga 2 o 3 Layer 5, the length and width are consistent with the p-GaN layer, and the thickness is 5nm;

[0074] The source electrode 6 and the drain electrode 7 are arranged on the AlGaN barrier layer and are ohmic contacts;

[0075] Ring-shaped gate electrode 8, set on Ga 2 o 3 layer, is a Schottky contact, and the length and width are related to Ga 2 o 3 The layers are consistent and are disposed between the source and drain electrodes, spacing them apart.

[0076] Detect the condu...

Embodiment 3

[0085] like Image 6 As shown, the enhancement mode GaN-based high electron mobility transistor, its structure includes from bottom to top:

[0086] - Si substrate layer;

[0087] A GaN buffer layer, unintentionally doped, with a thickness of 1 μm;

[0088] An AlGaN barrier layer with an Al composition of 0.2 and a thickness of 15 nm;

[0089] Strip p-GaN layer with Mg doping concentration of 1*10 19 cm -3 , with a thickness of 40nm;

[0090] Strip Ga 2 o 3 layer, the length and width are consistent with the p-GaN layer, and the thickness is 3nm;

[0091] The source electrode and the drain electrode are arranged on the AlGaN barrier layer and are ohmic contacts;

[0092] Strip gate electrodes, set on Ga 2 o 3 layer, is a Schottky contact, and the length and width are related to Ga 2 o3 The layers are consistent and are disposed between the source and drain electrodes, spacing them apart.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com