Hydrogen fuel cell waste heat utilization system

A technology of fuel cells and fuel cell stacks, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problem of low energy efficiency of hydrogen fuel cells, limited ship space, and inability to install large-scale air-cooled equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

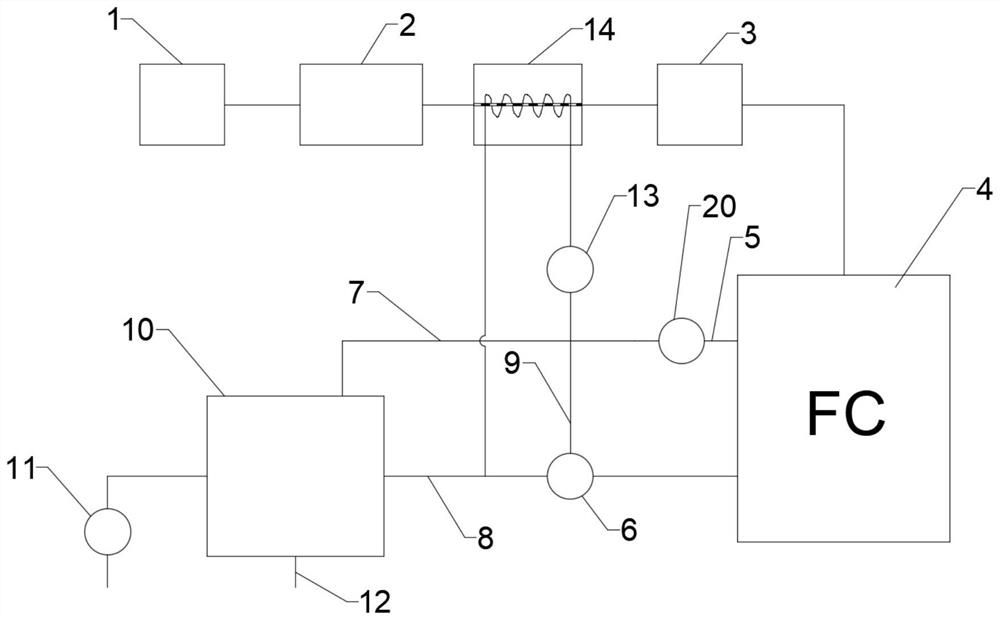

[0038] figure 1 It is a schematic diagram of the overall structure of the hydrogen fuel cell waste heat utilization system in Embodiment 1 of the present invention.

[0039] Such as figure 1 As shown, the hydrogen fuel cell waste heat utilization system provided by the embodiment of the present invention includes: a hydrogen storage tank 1, a gasification device 2, a pressurizing device 3, a fuel cell stack 4, a three-way solenoid valve 6, a first pipeline 5, The second pipeline 7, the third pipeline 9, the fourth pipeline 8, the first heat exchanger 10, the water pump 11, the fifth pipeline 12, the circulation pump 20 and the controller.

[0040]Wherein, the hydrogen storage tank 1 belongs to the prior art and is used for storing liquid hydrogen. The outlet of the hydrogen storage tank 1 communicates with the inlet of the gasification device 2 . The function of the gasification device 2 is to expand and vaporize the hydrogen gas coming out of the hydrogen storage tank 1, s...

Embodiment 2

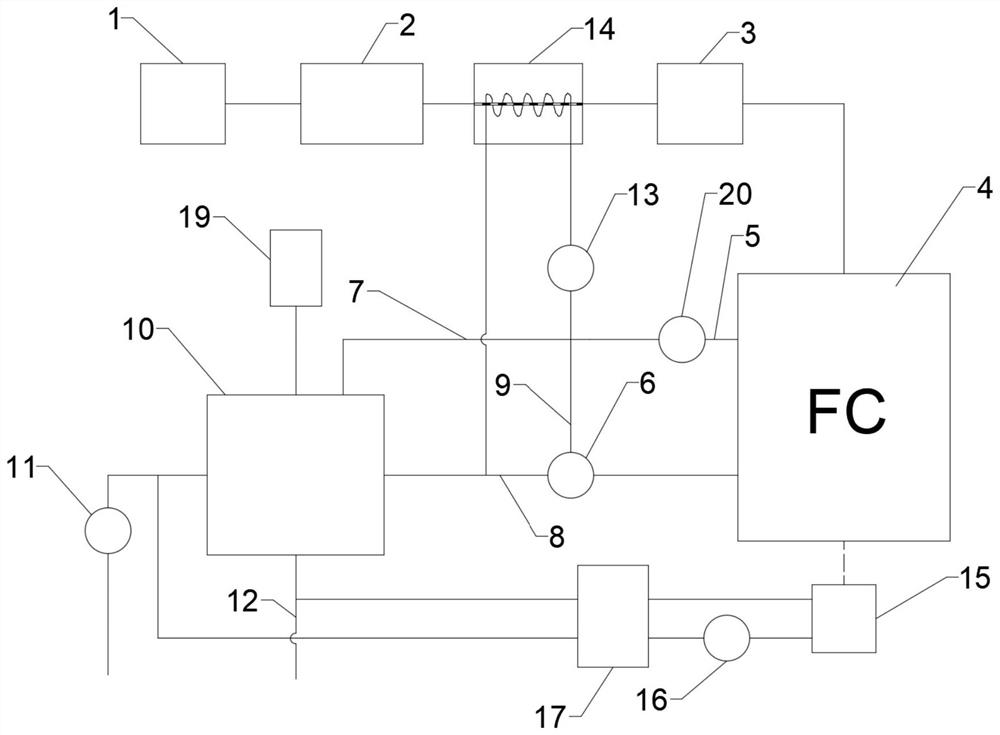

[0059] figure 2 It is a schematic diagram of the overall structure of the hydrogen fuel cell waste heat utilization system in Embodiment 2 of the present invention.

[0060] Such as figure 2 As shown, on the basis of the first embodiment, the hydrogen fuel cell waste heat utilization system provided by the embodiment of the present invention further includes: a heat dissipation device.

[0061] The output end of the fuel cell is provided with a DC-DC converter 15 . The DC-DC converter 15 will generate a certain amount of waste heat during operation.

[0062] The cooling device includes: a second auxiliary pump 16 and a third heat exchanger 17 .

[0063] The third heat exchanger 17 is arranged on the DC-DC converter 15, the second auxiliary pump 16 is connected in series on the heat exchange circuit between the third heat exchanger 17 and the DC-DC converter 15, the second auxiliary The pump 16 is electrically connected to the controller, the condensed water inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com