Spot welding method for aluminum material and aluminum material

A technology of aluminum and spot welding, applied in welding equipment, resistance welding equipment, welding/welding/cutting items, etc., can solve the problems of delay in welding operation, decrease in productivity, decrease in nugget roundness, etc., and achieve high joint strength , the effect of high-quality welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

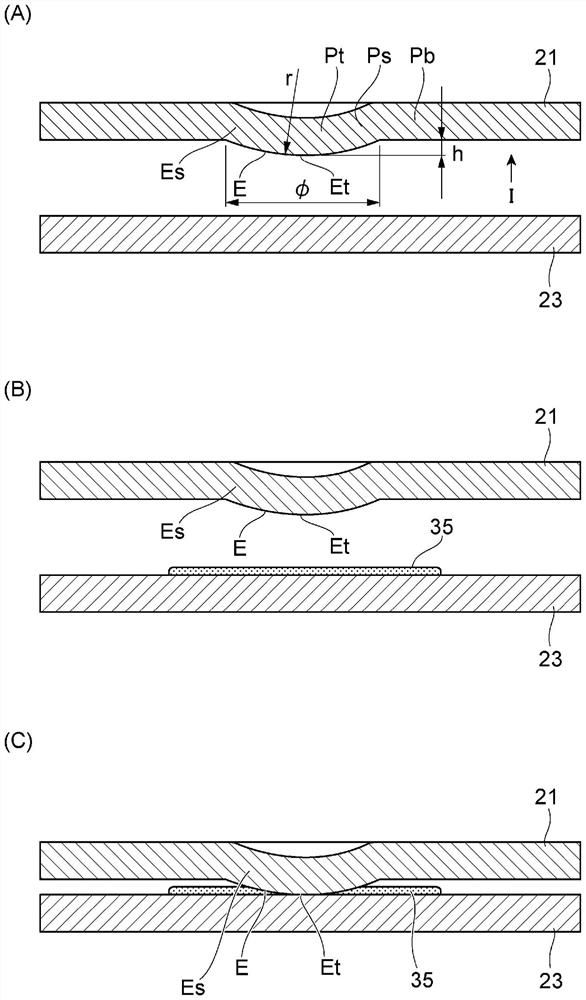

[0081] When two aluminum plates were spot-welded to form a joined body, reliefs of different heights were previously formed on one of the aluminum plates, and the state of the nugget formed in the prepared joined body was evaluated. Specifically, regarding the nugget after welding, the nugget diameter, roundness, penetration rate, penetration depth, weld thickness, and fracture diameter were measured and evaluated. In addition, evaluation was performed in the cases where no adhesive was applied (Test Example 1) and when the adhesive was applied (Test Example 2).

[0082]

[0083] (aluminum)

[0084] Material: A6022

[0085] Plate thickness t: 1.0mm

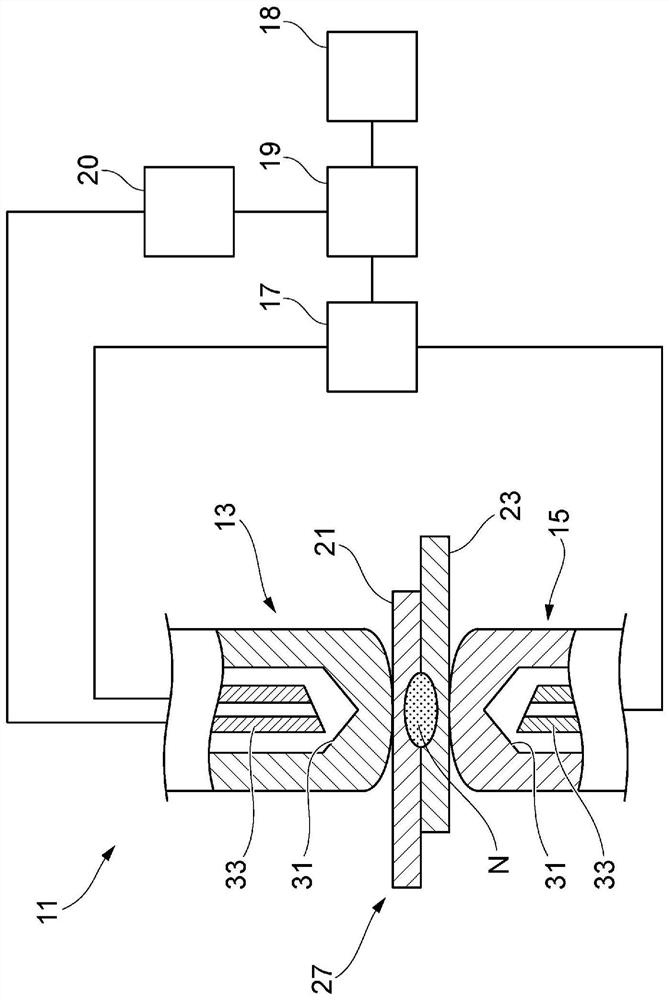

[0086] (electrode)

[0087] Type: Chromium copper (CrCu) R-shaped electrode

[0088] Front end curvature radius: 100mm

[0089] Electrode diameter (root diameter): 19mm

[0090] Pressure between electrodes: 2.7kN

[0091] Welding current: 22kA

[0092]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com