Instant liquid phase connection method of alumina ceramics

A technology of instantaneous liquid phase connection and alumina ceramics, which is applied in the field of welding, can solve the problems of insufficient high temperature resistance of joints, and achieve the effect of good high temperature resistance and high joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

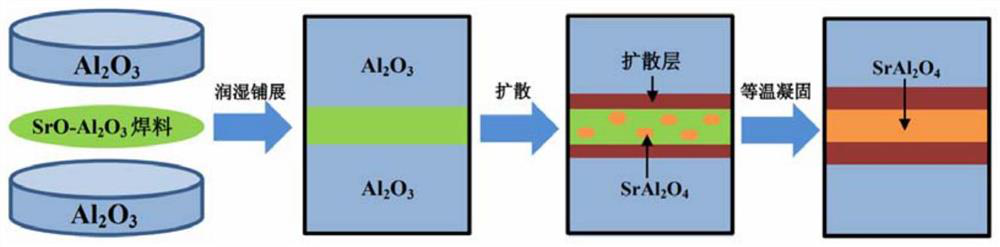

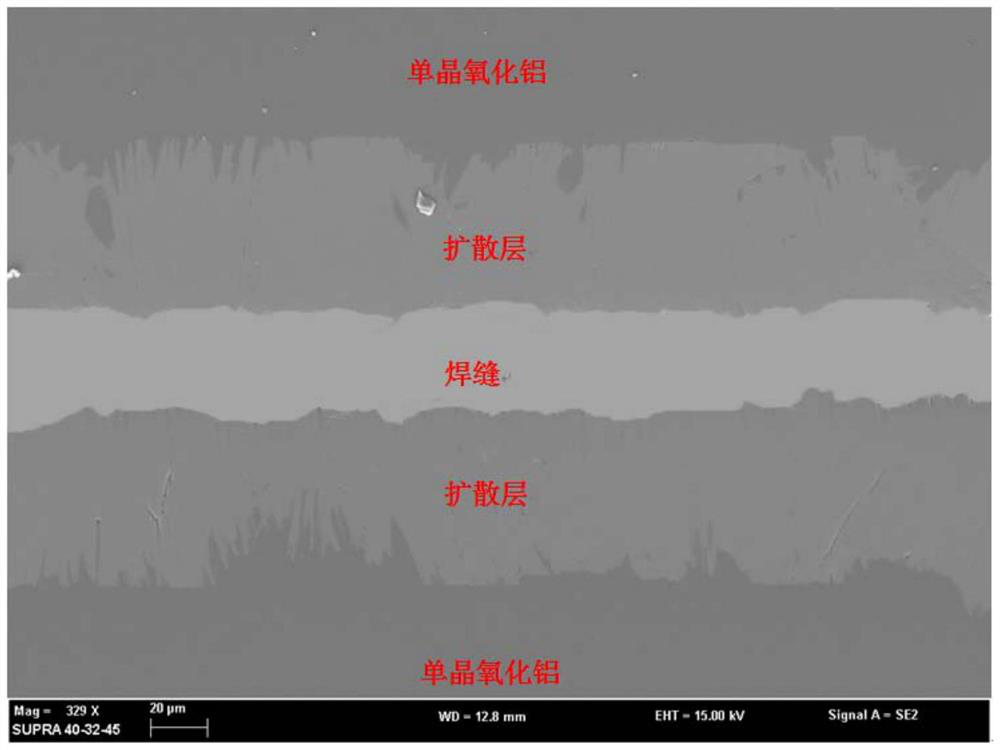

[0031] This embodiment provides a method for instant liquid-phase bonding of single-crystal alumina ceramics, which specifically includes the following steps:

[0032] (1) Material preparation: use 400#, 800#, 1200# sandpaper to polish in sequence, and then use diamond polishing paste with a particle size of 2.5 μm and 1.5 μm to polish the single crystal alumina ceramics to be welded. After polishing, the alumina ceramics were ultrasonically cleaned with acetone for 20 minutes, and then dried for later use.

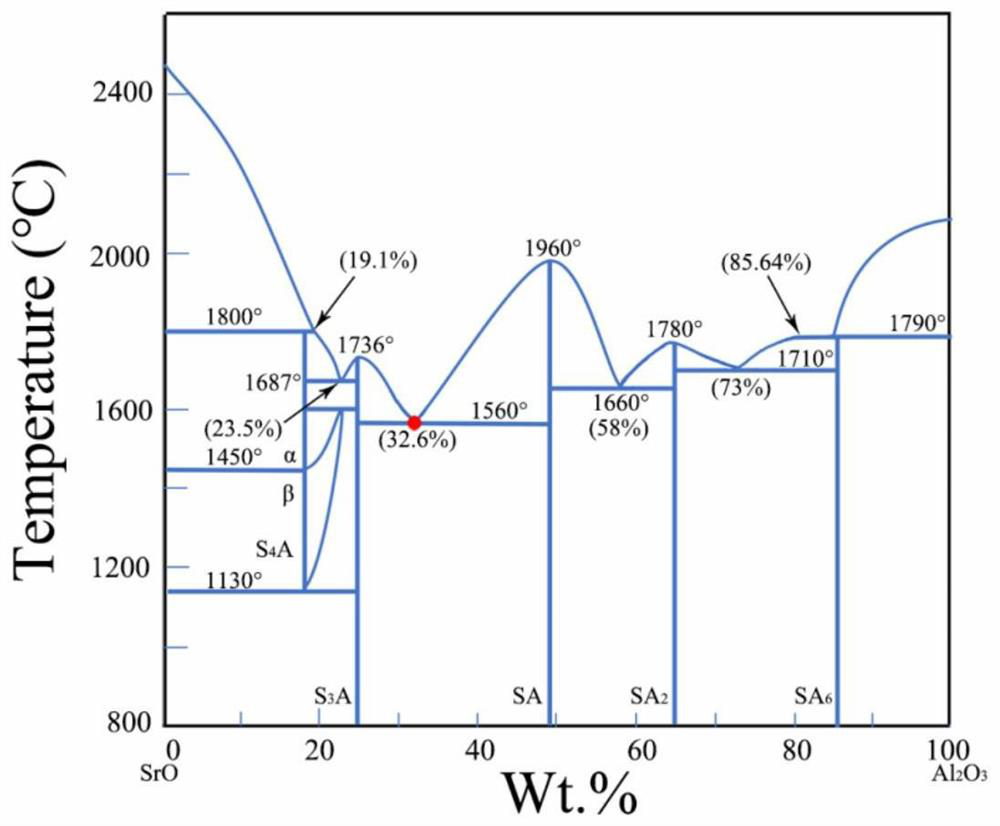

[0033] (2) Solder preparation: The weight percentage of solder is composed of: SrO is 67.4%, Al 2 o 3 was 32.6%. Weigh the oxide raw material according to the above ratio, put it into an agate ball mill jar for ball milling, the ball milling medium is ethanol, the balls are agate balls, the milling speed is 400 rpm, and the ball milling time is 15 hours. Drying after ball milling is completed, adding 1% PVA and 6% alcohol to the mixed powder weight after drying, and un...

Embodiment 2

[0038] This embodiment provides a method for instant liquid-phase bonding of single-crystal alumina ceramics, which specifically includes the following steps:

[0039] (1) Material preparation: use 400#, 800#, 1200# sandpaper to polish in sequence, and then use diamond polishing paste with a particle size of 2.5 μm and 1.5 μm to polish the single crystal alumina ceramics to be welded. After polishing, the alumina ceramics were ultrasonically cleaned with acetone for 20 minutes, and then dried for later use.

[0040] (2) Solder preparation: The weight percentage of solder is composed of: SrO is 67.4%, Al 2 o 3 was 32.6%. Weigh the oxide raw material according to the above ratio, put it into an agate ball mill jar for ball milling, the ball milling medium is ethanol, the balls are agate balls, the milling speed is 400 rpm, and the ball milling time is 15 hours. Drying after ball milling is completed, adding 1% PVA and 6% alcohol to the weight of the mixed powder into the drie...

Embodiment 3

[0045] This embodiment provides a method for instant liquid-phase bonding of single-crystal alumina ceramics, which specifically includes the following steps:

[0046] (1) Material preparation: use 400#, 800#, 1200# sandpaper to polish in sequence, and then use diamond polishing paste with a particle size of 2.5 μm and 1.5 μm to polish the single crystal alumina ceramics to be welded. After polishing, the alumina ceramics were ultrasonically cleaned with acetone for 20 minutes, and then dried for later use.

[0047] (2) Solder preparation: The weight percentage of solder is composed of: SrO is 67.4%, Al 2 o 3 was 32.6%. Weigh the oxide raw material according to the above ratio, put it into an agate ball mill jar for ball milling, the ball milling medium is ethanol, the balls are agate balls, the milling speed is 400 rpm, and the milling time is 10 h. Drying after ball milling is completed, adding 1% PVA and 6% alcohol to the mixed powder weight after drying, and uniformly m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com