Method for improving strength of steel-niobium laser welding joint

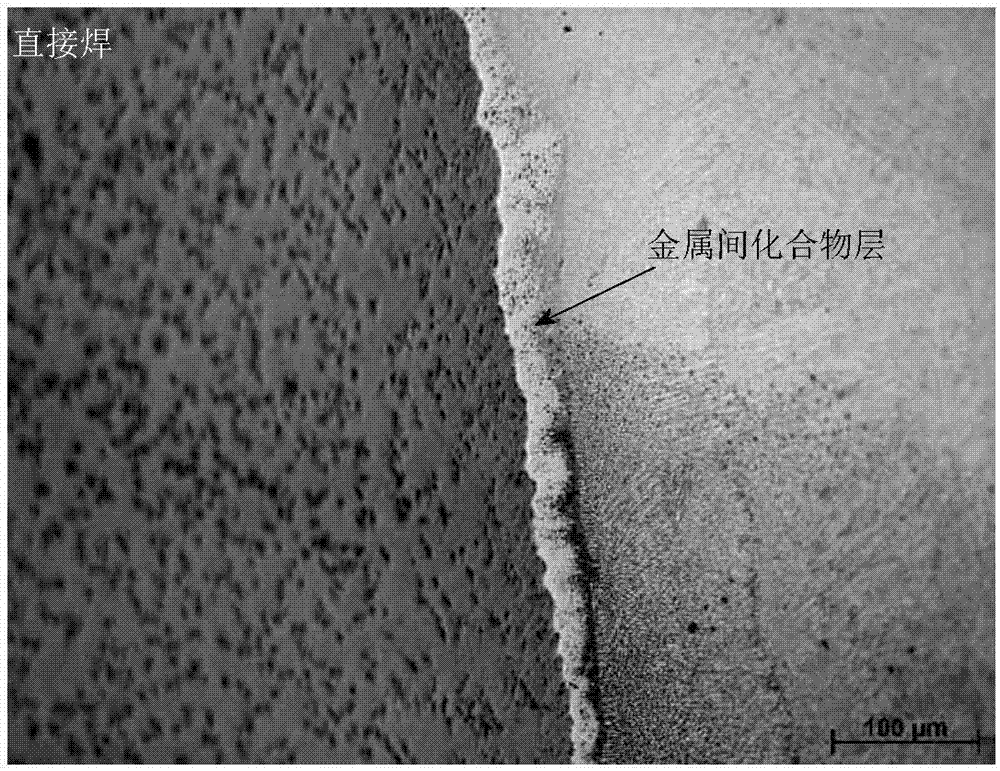

A joint strength, laser welding technology, applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problem of low joint strength, improve joint strength, inhibit the formation of intermetallic compounds, and improve tensile strength the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

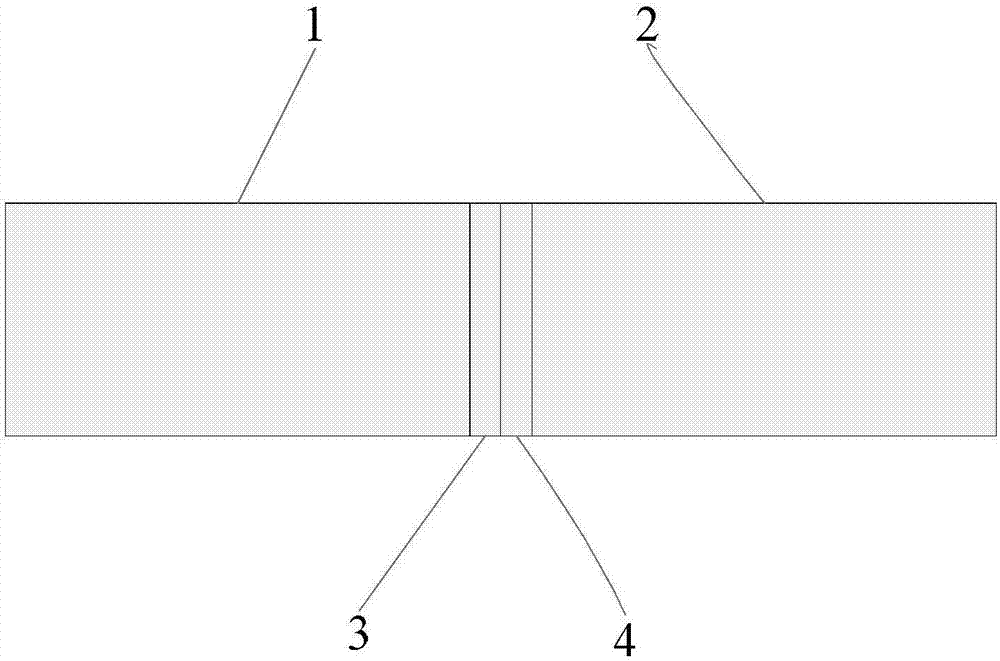

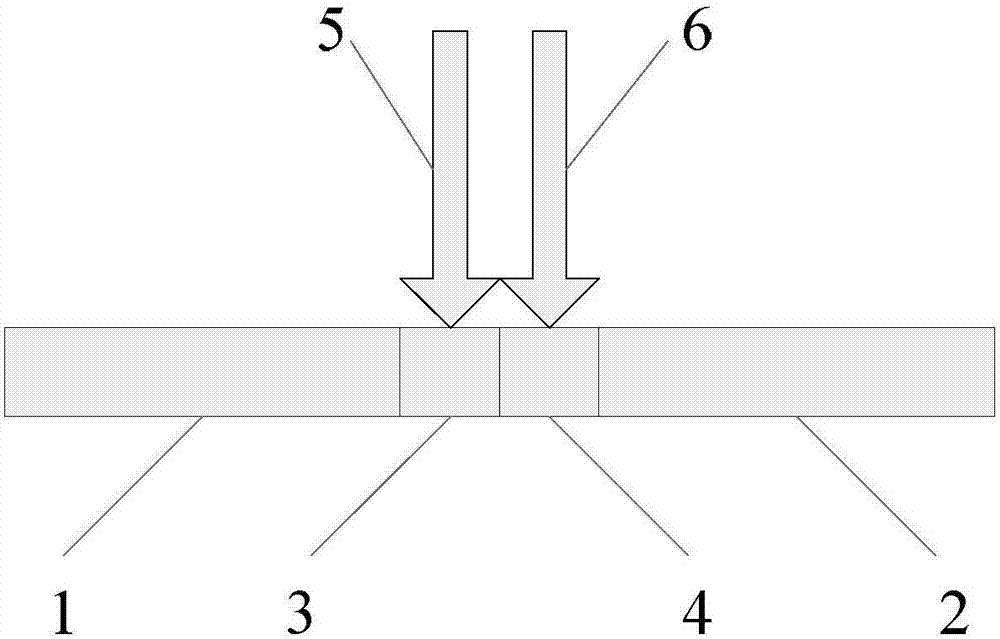

[0026] Embodiment 1: the welding method of this embodiment is realized according to the following steps (see figure 1 , figure 2 ):

[0027] (1) The base metal is Nb521 alloy and 304 stainless steel, and the size is 50mm×25mm×2mm. The middle layer is pure copper plate and pure tantalum plate, the size is 50mm×2mm×1mm;

[0028] (2) Polish the surface of the stainless steel plate, niobium plate, copper sheet and tantalum sheet with 80# water-resistant sandpaper to remove the surface oxide film and oil stains, and then use absorbent cotton to clean the surface of the test piece with acetone and alcohol respectively to ensure that the surface of the material is clean. pollute;

[0029] (3) The copper sheet and the tantalum sheet are pre-placed between the steel plate and the niobium sheet as a composite intermediate layer, the copper sheet is located on the side of the steel base material, and the tantalum sheet is located on the side of the niobium base material, that is, the...

Embodiment 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness of the copper sheet and the tantalum sheet in the intermediate layer is 0.8 mm. Others are the same as in Example 1.

[0033] No intermetallic compound is formed in the welded joint of this embodiment. The tensile strength of the joint is 136MPa.

Embodiment 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the thickness of the copper sheet and the tantalum sheet in the intermediate layer is 0.6 mm. Others are the same as in Example 1.

[0035] No intermetallic compound is formed in the welded joint of this embodiment. The tensile strength of the joint is 121MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com