Self-adaptive clamping mechanism of numerically controlled lathe

A self-adaptive, clamping mechanism technology, applied in the field of machine tools, can solve problems such as inability to cut shaft workpieces, inability to rotate the spindle, and low clamping accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

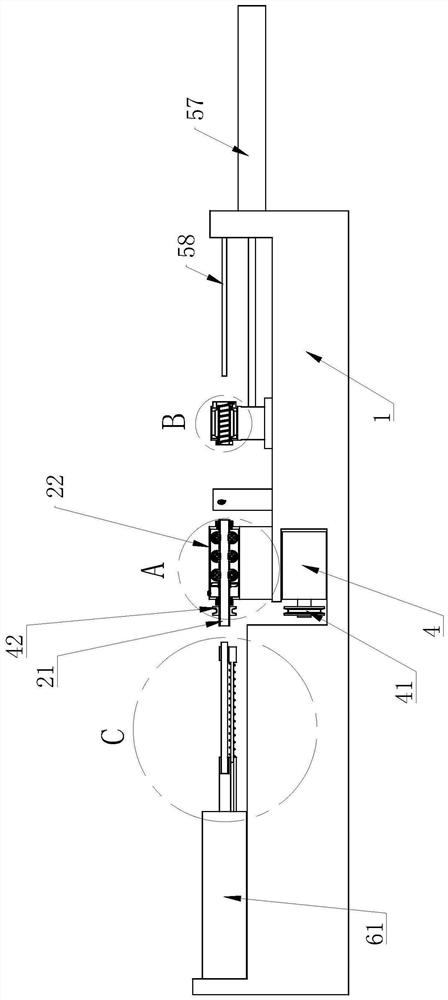

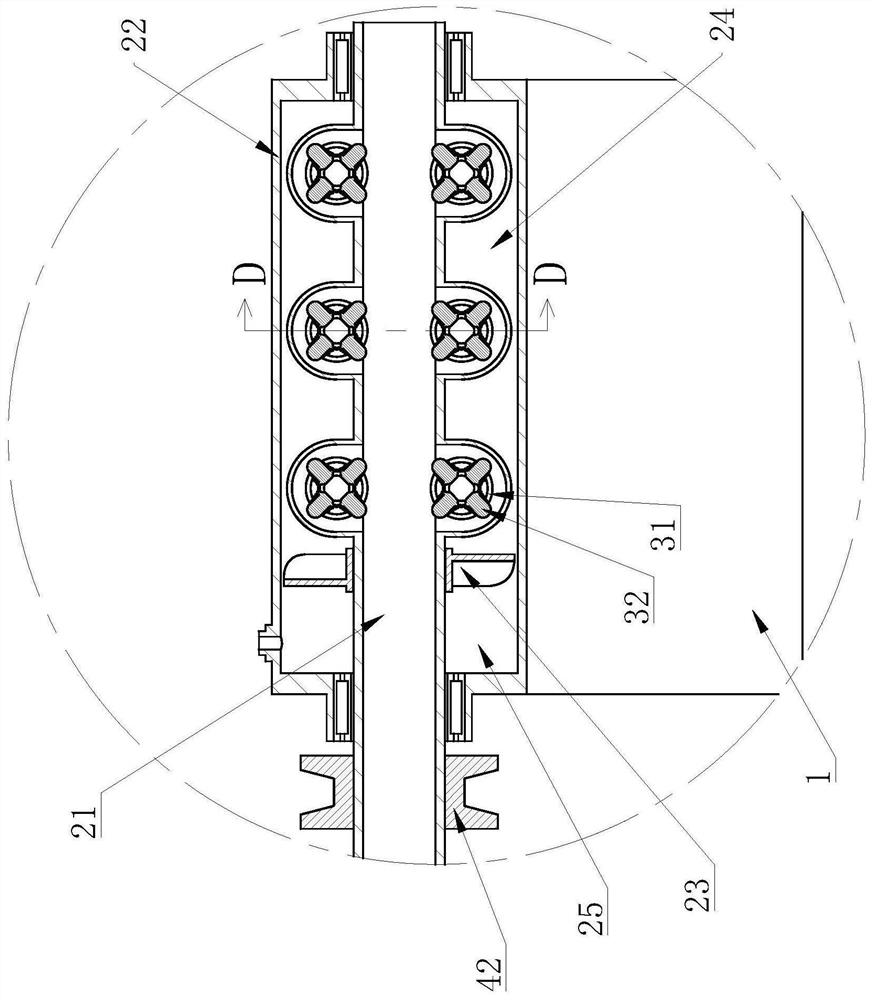

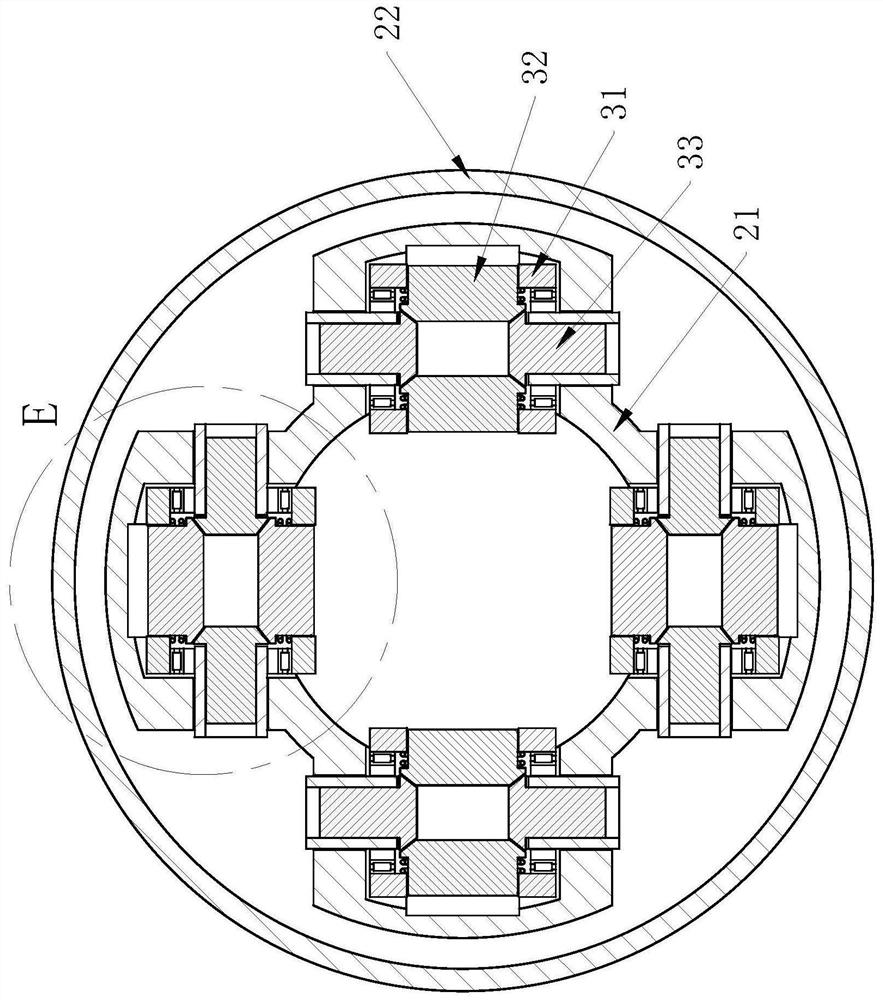

[0026] Such as figure 1 , figure 2 , image 3 with Image 6 As shown, the automatic feeding and discharging CNC lathe includes a main body 1, several workpiece clamping mechanisms, a feeding mechanism and a material discharging mechanism. The clamping assembly located on the main shaft 21, the clamping assembly includes a running wheel 31 rotatably connected to the main shaft 21, several clamping blocks 32 evenly distributed in the circumferential direction on the running wheel 31 and two plunger rods 33, two columns The stopper rod 33 is on the same straight line, the plunger rod 33 is perpendicular to the main shaft 21, each clamping block 32 is in the same plane, and the runner 31 is provided with a guide hole corre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap