Cold-chain anti-virus and anti-bacteria ethylene gas absorption preservative film (bag) and preparation method thereof

A technology of anti-virus and plastic wrap, applied in the chemical industry, can solve the problems of wasting manpower, financial resources, and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

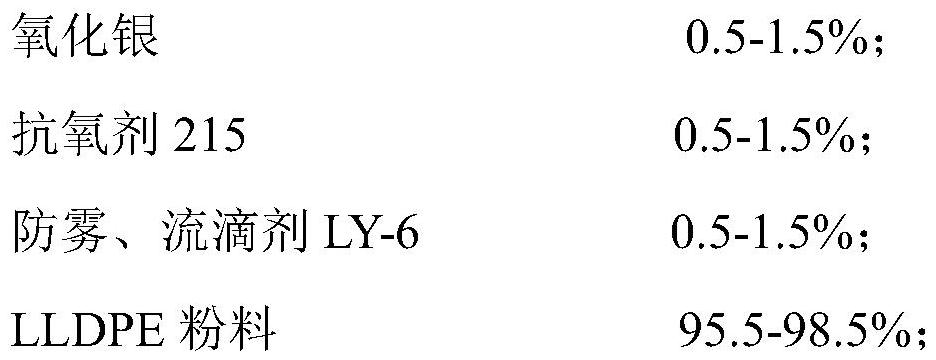

[0058] The cold-chain anti-virus and anti-bacteria masterbatch is made of the following raw materials in mass percentage:

[0059]

[0060] Its preparation method concrete steps are as follows:

[0061] Weigh a certain weight of materials according to the formula, put them into a high-speed mixer and stir for 5 minutes, transport the uniformly mixed materials into the hopper of the extruder, and extrude and granulate through the twin-screw extruder. Rotational speed: 65N / min; temperature control: 160°C; the masterbatch is obtained by air-cooling and hot-cutting at the machine head, packed into bags (25kg / bag), and put into storage for standby.

Embodiment 2

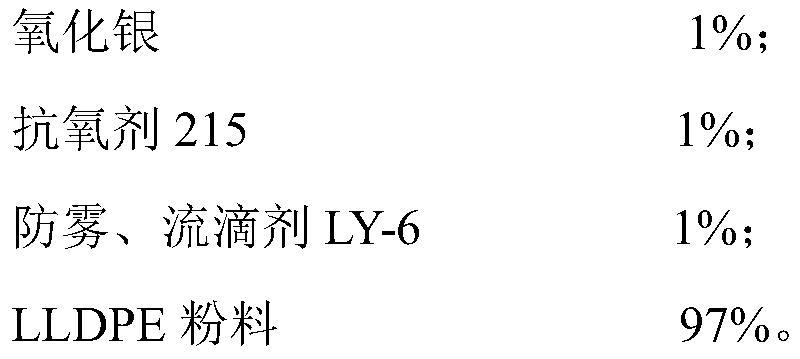

[0063] The cold-chain anti-virus and anti-bacteria masterbatch is made of the following raw materials in mass percentage:

[0064]

[0065] Its preparation method concrete steps are as follows:

[0066]Weigh a certain weight of materials according to the formula, put them into a high-speed mixer and stir for 5 minutes, transport the uniformly mixed materials into the hopper of the extruder, and extrude and granulate through the twin-screw extruder. Rotational speed: 50N / min; temperature control: 150°C; the masterbatch is obtained by air-cooling and hot-cutting at the machine head, and after bagging (25kg / bag), it is put into storage for standby.

Embodiment 3

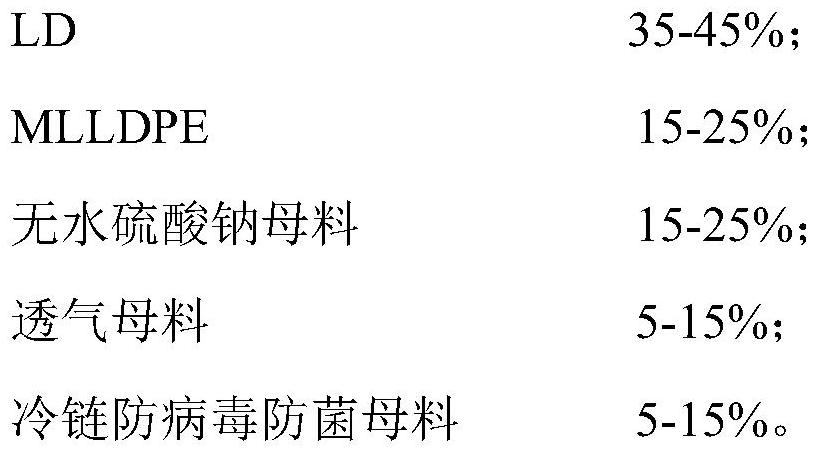

[0068] The cold-chain anti-virus and anti-bacteria masterbatch is made of the following raw materials in mass percentage:

[0069]

[0070] Its preparation method concrete steps are as follows:

[0071] Weigh a certain weight of materials according to the formula, put them into a high-speed mixer and stir for 5 minutes, transport the uniformly mixed materials into the hopper of the extruder, and extrude and granulate through the twin-screw extruder. Rotational speed: 80N / min; temperature control: 175°C; the masterbatch is obtained by air-cooling and hot-cutting at the machine head, and after being bagged (25kg / bag), it is put into storage for standby.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com