Zinc sulfate purification system based on high-temperature and high-pressure zinc powder

A purification system, high temperature and high pressure technology, applied to the improvement of process efficiency, etc., can solve the problem of low purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

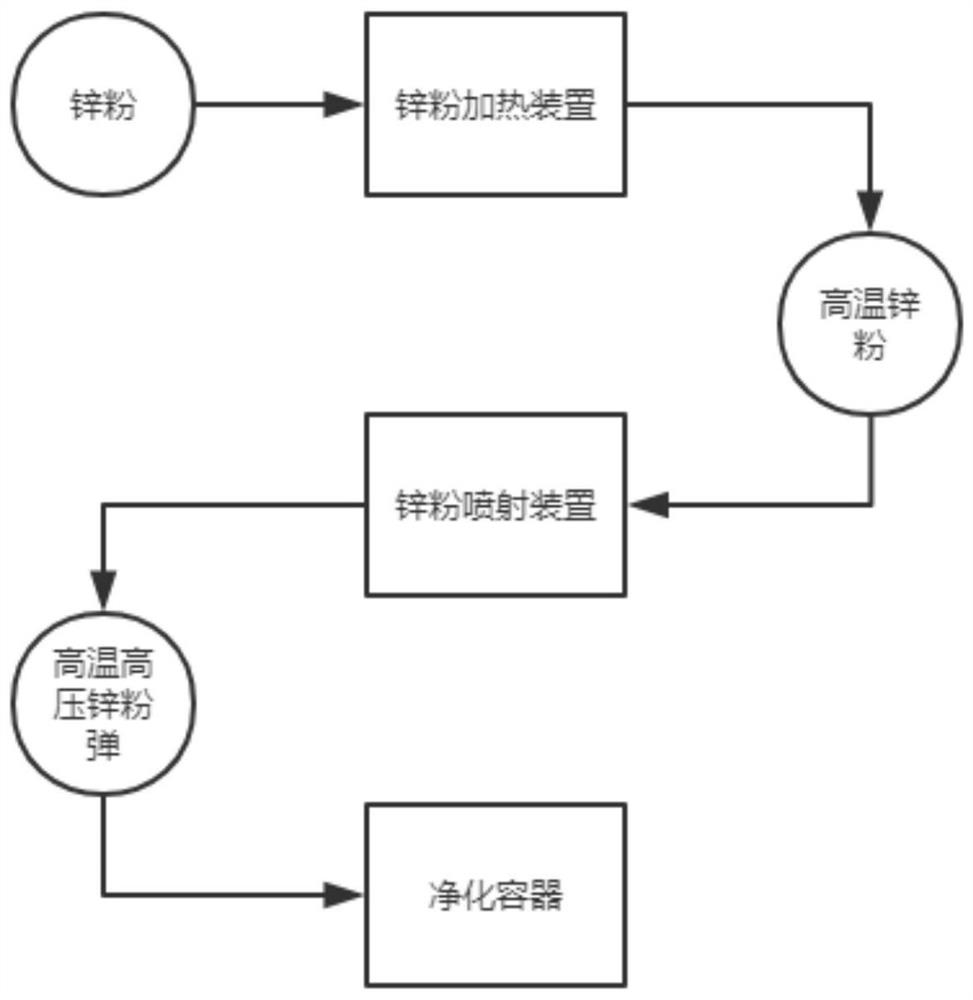

[0035] This embodiment provides a zinc sulfate purification system based on high temperature and high pressure zinc powder, including a zinc powder heating device, a zinc powder spraying device and a purification container, the zinc powder heating device is used to heat the zinc powder to a fixed temperature, the The zinc powder injection device is used to assemble high-temperature zinc powder into a high-pressure zinc powder bomb and spray the zinc powder bomb into the zinc sulfate solution in the purification container, and the purification container is used to absorb the heat generated by the reaction of zinc powder and zinc sulfate solution Keep the zinc sulfate solution at a fixed temperature;

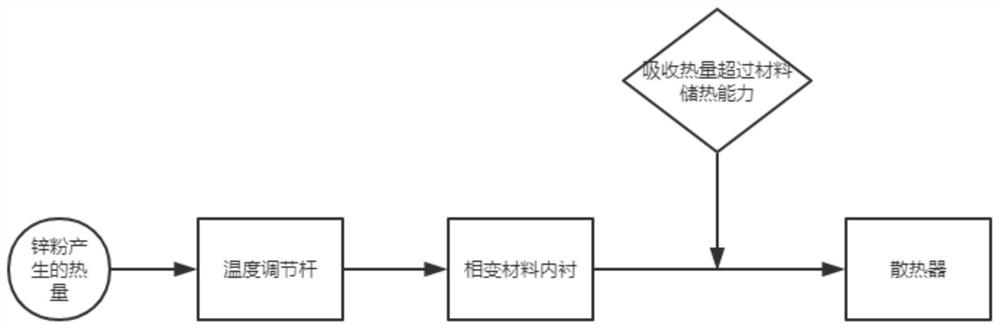

[0036] The purification container contains a container body, a phase change material lining and a temperature regulating rod, the container body is used to carry zinc sulfate liquid, the two ends of the temperature regulating rod are connected to the phase change material lining, t...

Embodiment 2

[0054] This embodiment includes all the content of the above embodiments, combined with figure 1 , the present embodiment provides a zinc sulfate purification system based on high-temperature and high-pressure zinc powder, including a zinc powder injection device, a zinc powder heating device and a purification container, and the zinc powder heating device injects the zinc powder into the zinc powder injection after heating the zinc powder In the device, the zinc powder injection device wraps the high-temperature zinc powder with a layer of high-pressure inert gas to form a zinc powder bomb, and sprays the zinc powder bomb into the zinc sulfate solution in the purification container, and the purification container It is used to store the zinc sulfate solution and provide a temperature-stable environment, so that the zinc powder in the zinc powder bomb can quickly react with the zinc sulfate solution to replace other metal impurities;

[0055] The purge vessel includes a main b...

Embodiment 3

[0071] This embodiment includes all the contents of the above-mentioned embodiments. The control module of this embodiment is used to control the blocking plate of the injection pipe, the valve below the metering pipe, the valve of the drive assembly and the piston of the drive assembly. For the convenience of control , the valve below the metering tube is also arranged on the zinc powder spraying device, and the control module controls the amount of zinc powder sprayed into the zinc sulfate solution each time and two adjacent sprays of zinc powder by controlling the above-mentioned components. The time interval between bombs makes the zinc powder bomb sprayed each time have the most efficient purification effect;

[0072] The total zinc powder volume V required to purify the zinc sulfate solution 总 for:

[0073]

[0074] Among them, V y is the volume of zinc sulfate solution in the purification container, m z is the impurity mass in the unit zinc sulfate solution, ρ Zn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com