Construction method for stopping underground water of building foundation pit

A groundwater and foundation pit technology, applied in construction, infrastructure engineering, excavation, etc., can solve problems such as hidden safety hazards, poor lap joints, water leakage, etc., and achieve significant water stop effects and cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The technical solutions and features of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be noted that various modifications can be made to the embodiments disclosed herein, therefore, the embodiments disclosed in the specification should not be regarded as limitations on the present invention, but only as examples of embodiments, and its purpose is to make the present invention The features of the invention are self-evident.

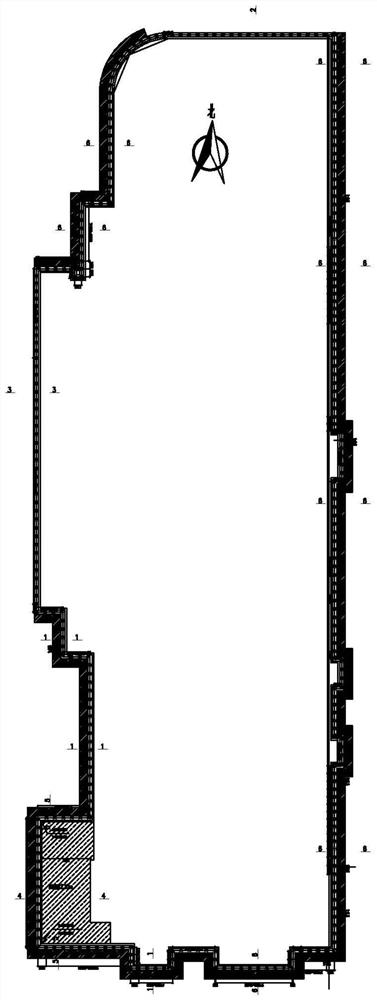

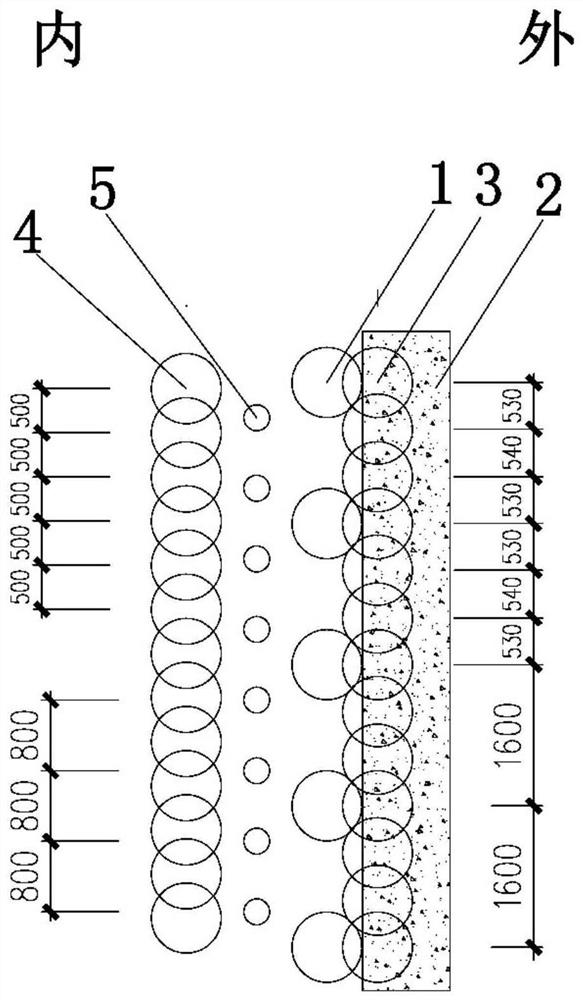

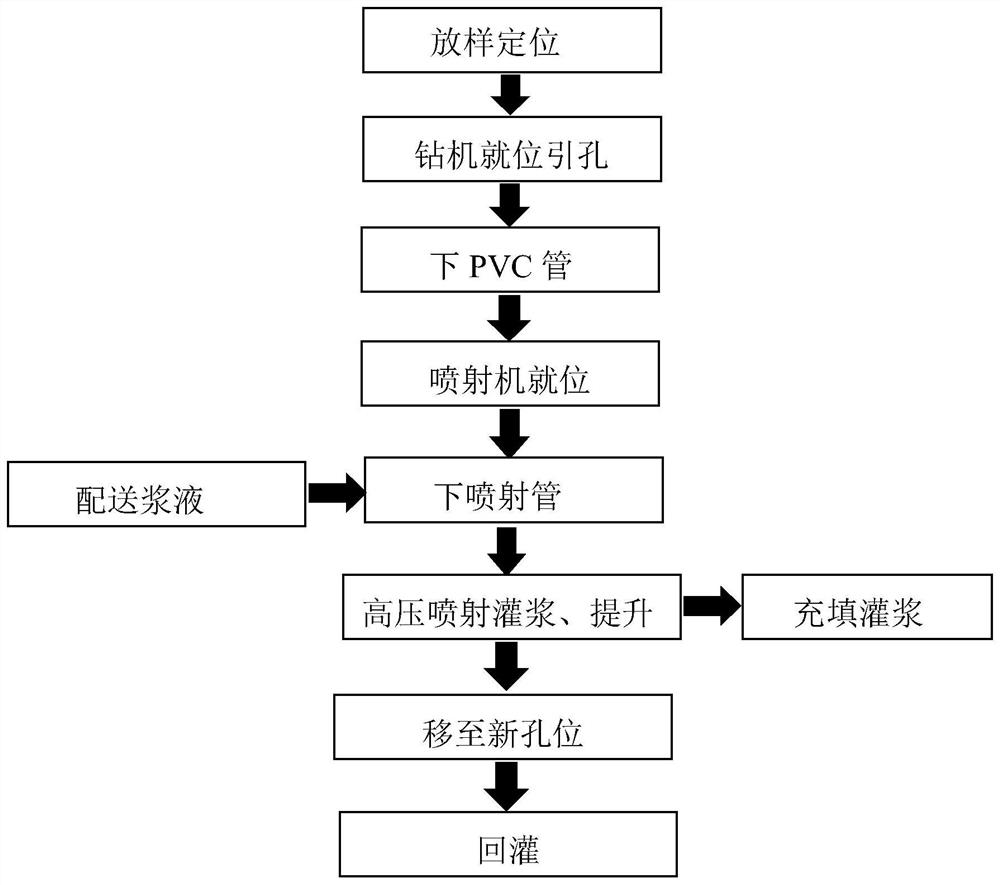

[0083] When digging a building foundation pit, as the depth of the building foundation pit increases, it is necessary to pour a circle of support piles around the building foundation pit, and then pour crown beams on the top of the support piles, and through the crown beams, each support pile Connect them together, and finally, fix several anchor cables and anchor rods between the surroundings of the foundation pit and the support piles / crown beams for further reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com