Double-air-passage self-pressure-relief single-mode microwave reaction system

A single-mode microwave and reaction system technology, applied in the field of analytical instruments, to avoid accumulation, simplify the structure of test tube assemblies, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

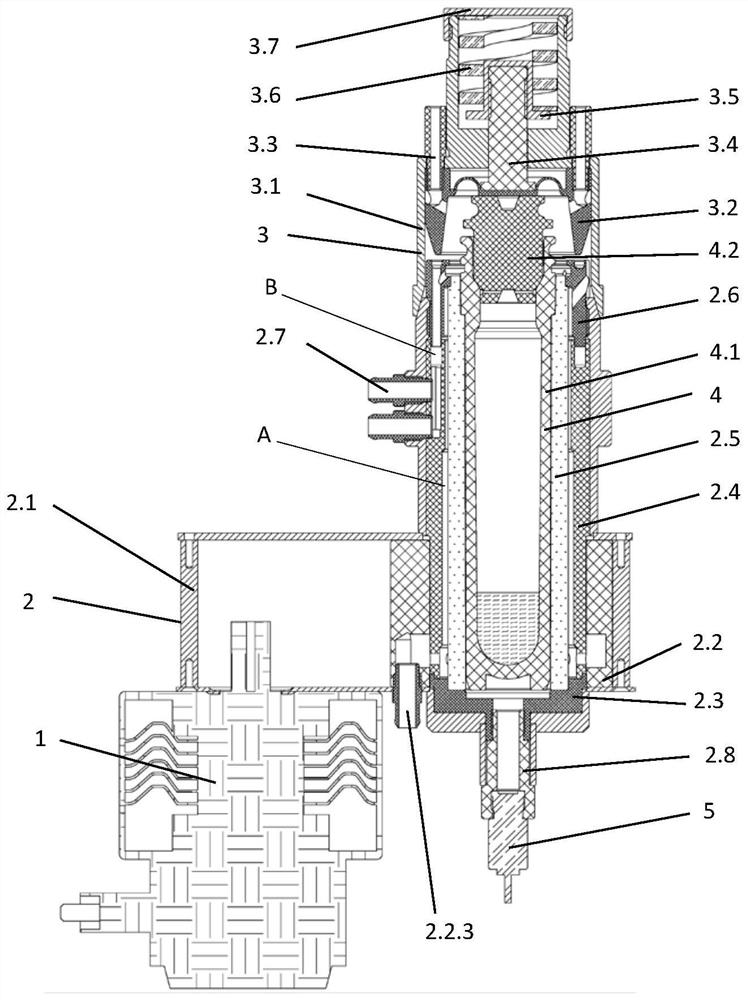

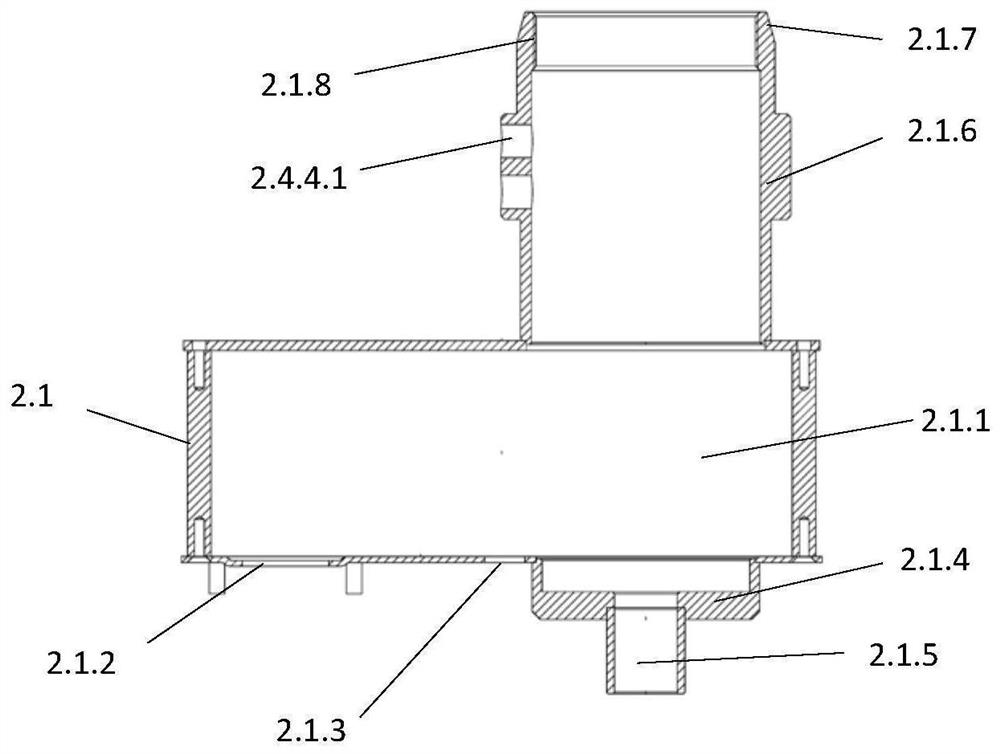

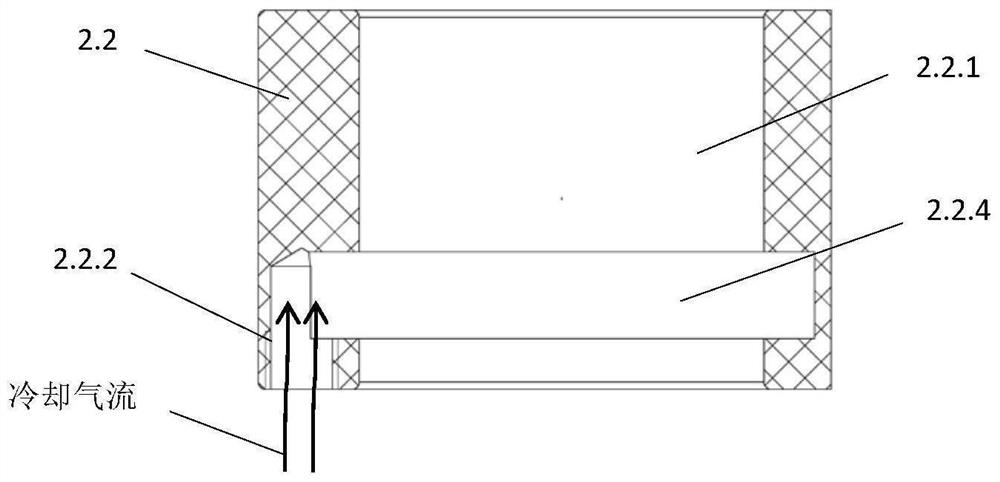

[0083] According to the technical solution of the present invention, a double-airway self-relieving single-mode microwave reaction system is provided, including a magnetron, a single-mode cavity assembly, a single-mode sealing cover assembly, a test tube assembly and an infrared temperature sensor; it is mainly used in Fully automatic microwave digestion instrument.

[0084]In this technical solution, the magnetron is used to generate microwaves and feed them into the single-mode cavity to heat the samples in the cavity; the single-mode cavity assembly is used to fix the test tube assembly, and forms a seal around the test tube assembly The microwave heating cavity; the single-mode sealing cover assembly is used to seal the test tube and realize the self-relieving function of the single-mode test tube assembly; the test tube assembly is used to accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com