Smelting equipment for manganese-silicon alloy

A manganese-silicon alloy and equipment technology, which is applied in the field of manganese-silicon alloy preparation equipment, can solve problems affecting the quality of output products and uneven heating of smelting furnaces, and achieve the effects of improving quality, accelerating combustion, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

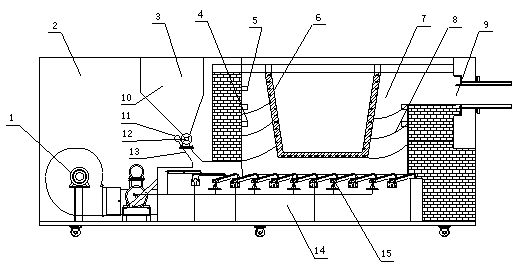

[0016] Embodiment 1 of the present invention: a kind of smelting equipment of manganese-silicon alloy, comprises melting furnace, and described melting furnace comprises melting furnace body 2, and the lower part of melting furnace body 2 is provided with blower 1 and air inlet pipe 14, and blower 1 and inlet The air duct 14 communicates, the top of the air inlet duct 14 is provided with a fire grate 15, the top of the fire grate 15 is provided with a combustion chamber 7, and one side of the combustion chamber 7 is provided with a fuel supply device 3, and the fuel supply device 3 and the combustion chamber 7 are connected; the combustion chamber 7 is cylindrical, and the combustion chamber 7 is provided with a melting pool 6, and the melting pool 6 is in the shape of a truncated cone, and the side of the combustion chamber 7 away from the fuel supply device 3 is provided with a fire outlet 9; A deflector 8 is provided on the inner wall, the deflector 8 is a spiral plate, one ...

Embodiment 2

[0018] Embodiment 2: A kind of smelting equipment of manganese-silicon alloy, comprises melting furnace, and described melting furnace comprises melting furnace body 2, and the lower part of melting furnace body 2 is provided with air blower 1 and air inlet pipe 14, and air blower 1 and air inlet pipe 14 Communication, the top of the air inlet pipe 14 is provided with a fire grate 15, the top of the fire grate 15 is provided with a combustion chamber 7, and one side of the combustion chamber 7 is provided with a fuel supply device 3, and the fuel supply device 3 communicates with the combustion chamber 7; The combustion chamber 7 is cylindrical, and the combustion chamber 7 is provided with a molten pool 6, and the molten pool 6 becomes a truncated cone, and the side of the combustion chamber 7 away from the fuel supply device 3 is provided with a fire outlet 9; There are deflectors 8, the deflectors 8 are spiral plates, one side of the deflectors 8 is fixed on the combustion c...

Embodiment 3

[0020] Embodiment 3: A kind of smelting equipment of manganese-silicon alloy, comprises melting furnace, and described melting furnace comprises melting furnace body 2, and the lower part of melting furnace body 2 is provided with air blower 1 and air inlet pipe 14, and air blower 1 and air inlet pipe 14 Communication, the top of the air inlet pipe 14 is provided with a fire grate 15, the top of the fire grate 15 is provided with a combustion chamber 7, and one side of the combustion chamber 7 is provided with a fuel supply device 3, and the fuel supply device 3 communicates with the combustion chamber 7; The combustion chamber 7 is cylindrical, and the combustion chamber 7 is provided with a molten pool 6, and the molten pool 6 becomes a truncated cone, and the side of the combustion chamber 7 away from the fuel supply device 3 is provided with a fire outlet 9; There are deflectors 8, the deflectors 8 are spiral plates, one side of the deflectors 8 is fixed on the combustion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com