Quick loading and unloading tube furnace

A technology for loading and unloading materials and tube furnaces, which is applied in the field of material processing, can solve problems such as difficult control of strength, complicated operation process, and poor control, and achieve the effects of preventing heat loss, simple operation, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

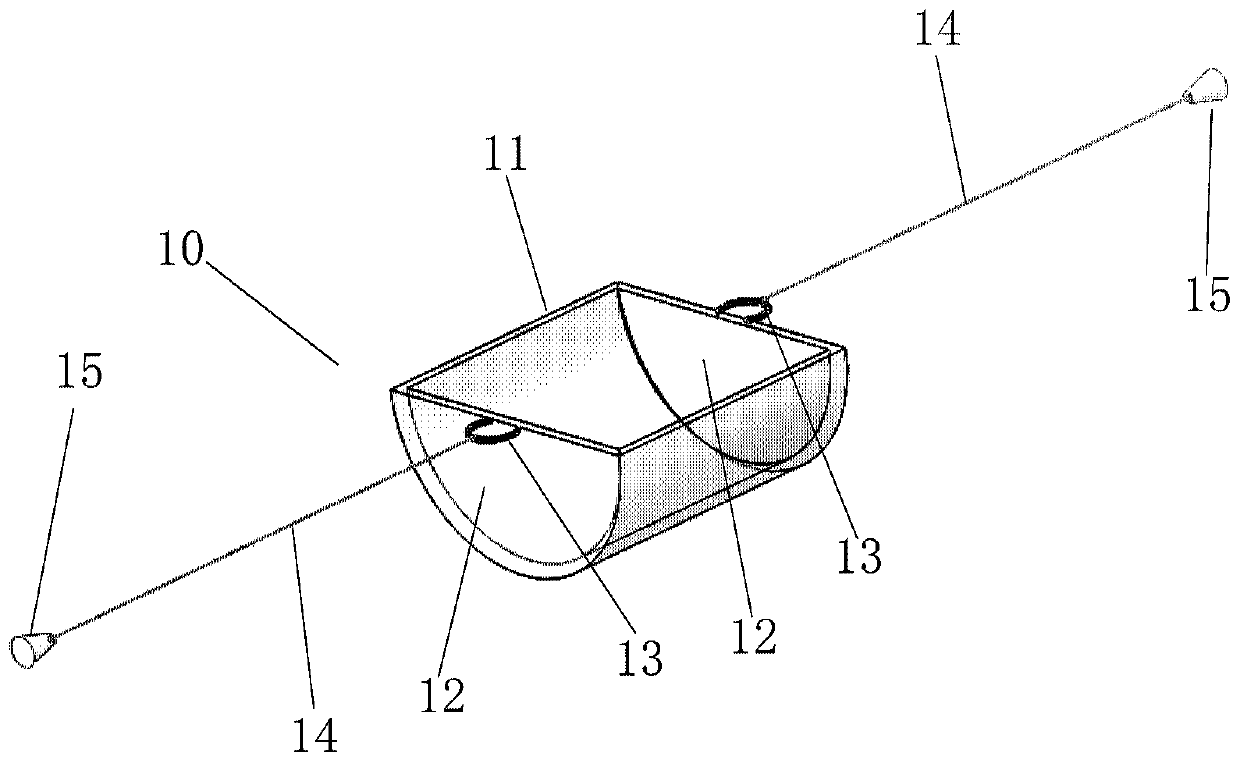

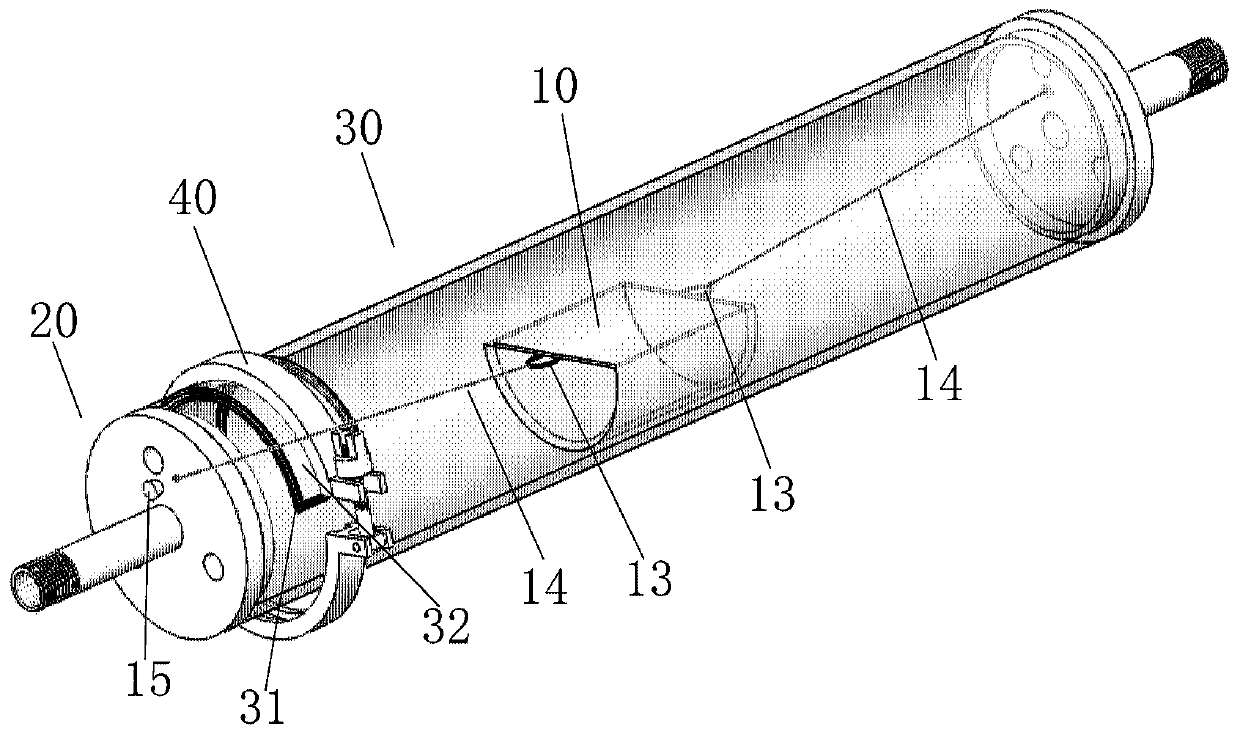

[0022] see Figure 1 to Figure 3 As shown, the present invention provides a kind of fast loading and unloading tube furnace, comprising:

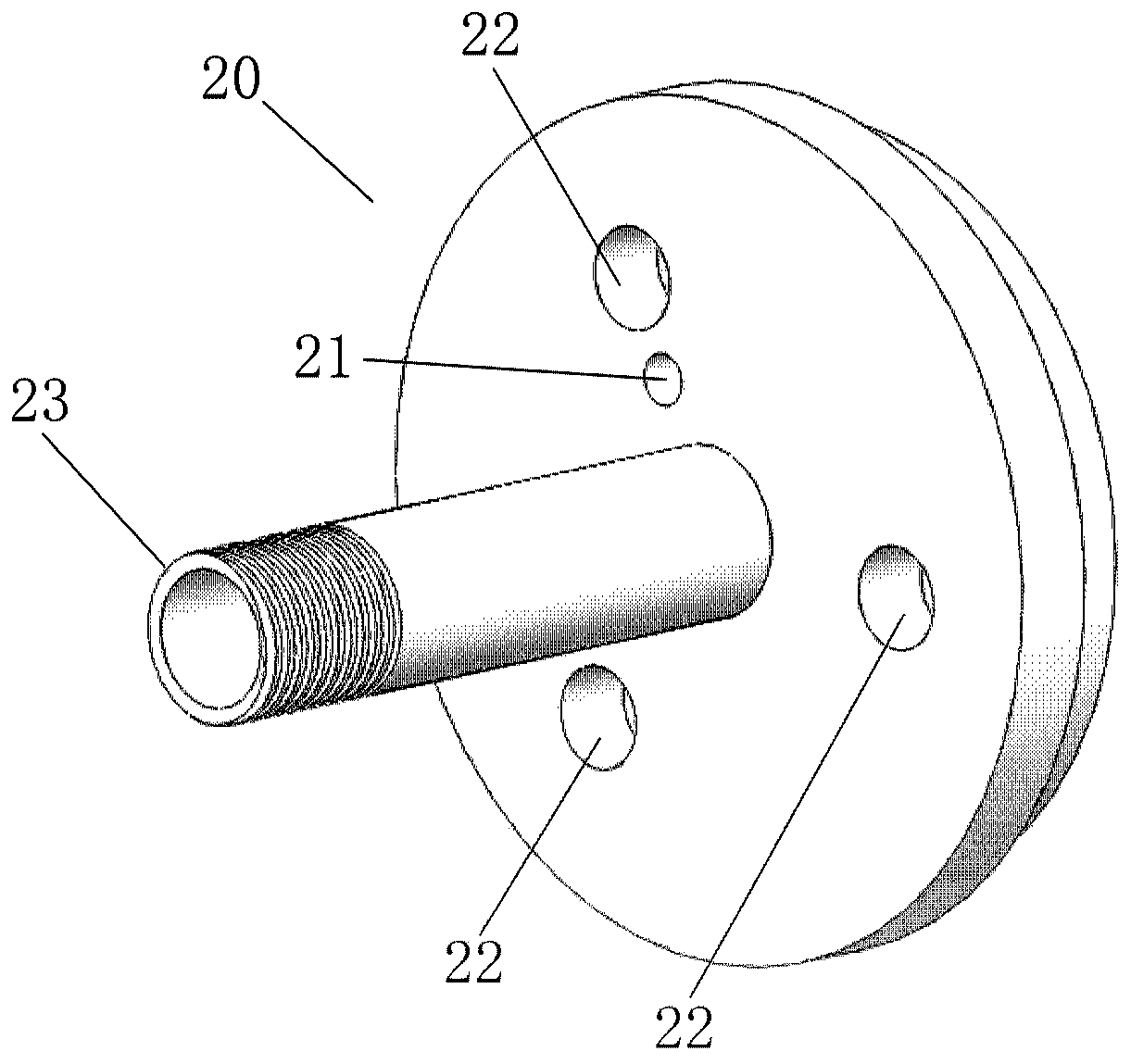

[0023] A quartz boat 10, which is a semi-cylindrical tank body 11, has a circular ring 13 on both ends 12 of the quartz boat 10, a chain 14 is connected to each of the circular rings 13, and a metal plug 15 is connected to the other end of the chain 14 , the quartz boat 10 and the ring 13 are an integral structure, and the material is quartz; the quartz boat 10 is a semi-cylindrical structure with a double-ended ring, and its size should be determined in conjunction with the furnace tube 30. Generally, the outer surface of the quartz boat 10 is The diameter is smaller than the inner diameter of the furnace tube, which can ensure free movement in the furnace tube 10; the inner bottom of the quartz boat 10 should be designed to match the shape of the clamp used, so that the contact surface between the clamp and the quartz boat 10 is the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com