An Indoor Soil Explosion Dust Test System

A testing system and soil technology, applied in the field of explosion testing, can solve the problems of lack of test verification, high risk, poor repeatability, etc., and achieve the effects of controllable test conditions, strong repeatability, and easy movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

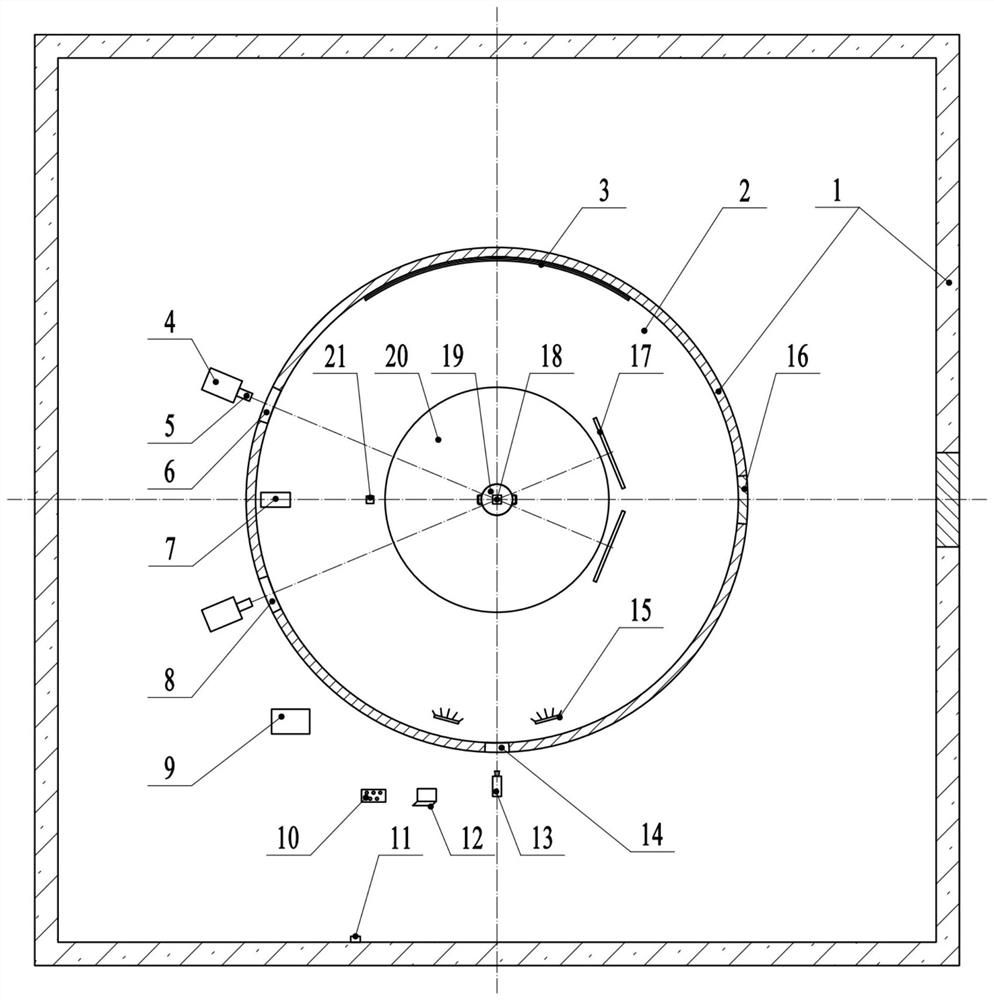

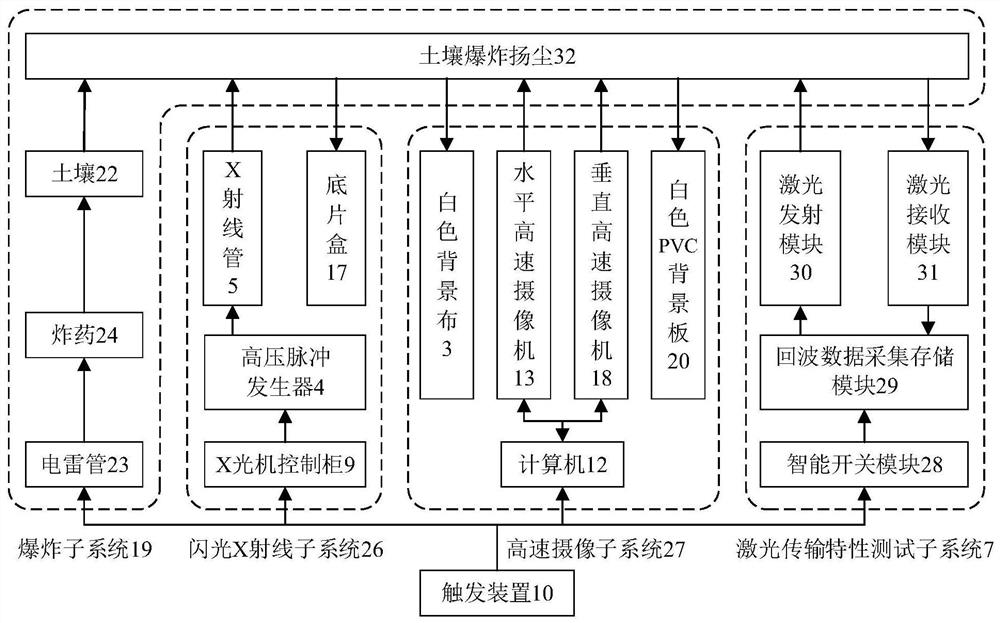

[0032] as attached figure 1 And attached figure 2 As shown, the present invention provides a kind of indoor soil explosion dust test system, and this system is triggered by explosion hole 1, explosion subsystem 19, flash X-ray subsystem 26, high-speed camera subsystem 27, laser transmission characteristic test subsystem 7, The device 10 and the temperature-hygrometer 21 are composed.

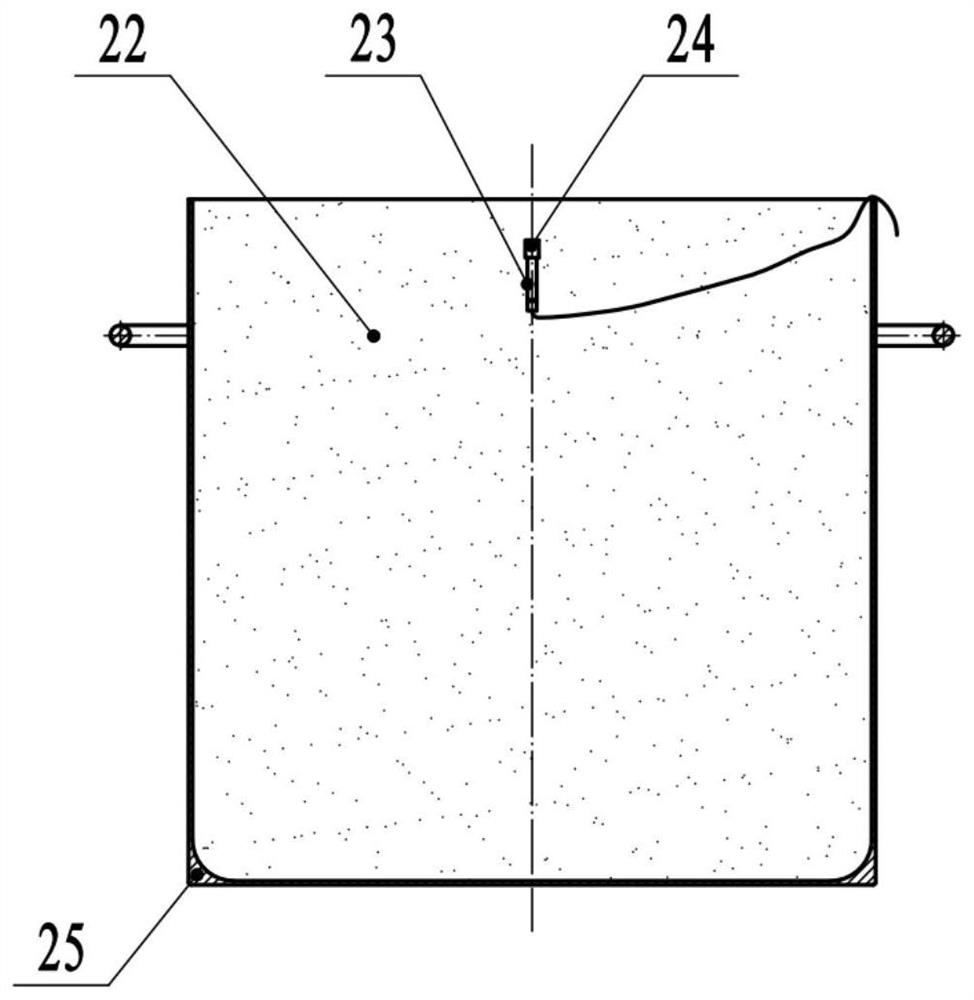

[0033] Wherein, the explosion subsystem 19 includes a steel drum 25, soil 22, explosives 24 and an electric detonator 23, the steel drum 25 is placed at the center of the ground in the inner layer 2 of the explosion hole, the soil 22 is installed in the steel drum 25, the explosives 24 and the electric detonator 23 After being connected by pressure-sensitive adhesive tape, they are buried in the soil 22 at a certain depth, and the axis lines of the two are coincident with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com