Method for measuring content of acetic acid in acetic acid production in real time

A technology for real-time measurement of acetic acid content, applied in measuring devices, identification of molecular entities, instruments, etc., can solve the problems of not being able to grasp the quality of acetic acid in real time, and achieve the effect of simple operation and improved data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

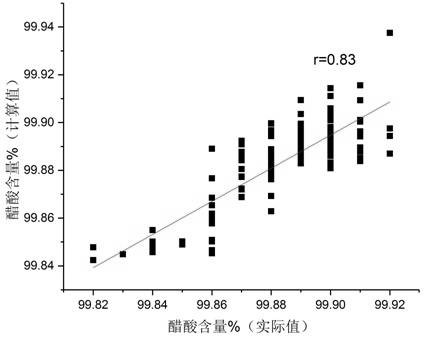

[0042] Example 1: The modeling result of the quantification of acetic acid content based on partial least squares regression, such as figure 1 Indicated.

[0043] Depend on figure 1 It can be seen that the model of the forecast value of the model and the correlation coefficient of the measured value are 0.83.

Embodiment 2

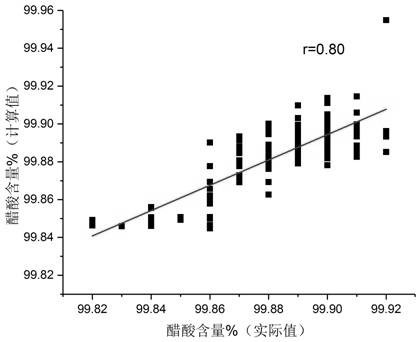

[0044] Example 2: For 125 data, the quantification of the acetic acid content quantitative forecast model based on partial least squares regression, such as figure 2 Indicated.

[0045] Depend on figure 2 It can be seen that the prediction value of the model and the correlation coefficient of the measured value are 0.8.

Embodiment 3

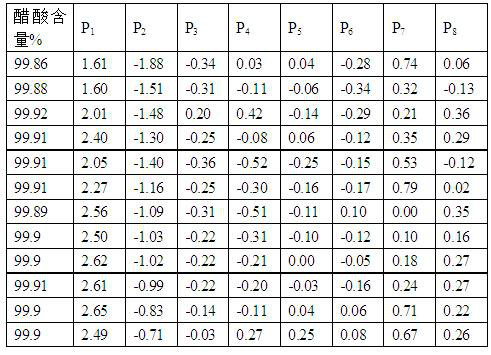

[0046] Example 3: The acetic acid content forecast model based on 31 bias minimum multiplied regression is predicted to the newly collected 31 samples, and the results are shown in Table 5.

[0047] Serial number Acetic acid content% Serial number Acetic acid content% Serial number Acetic acid content% 1 99.88 12 99.89 23 99.90 2 99.89 13 99.90 24 99.89 3 99.90 14 99.90 25 99.90 4 99.89 15 99.91 26 99.88 5 99.90 16 99.87 27 99.84 6 99.87 17 99.86 28 99.86 7 99.87 18 99.90 29 99.90 8 99.88 19 99.85 30 99.88 9 99.86 20 99.89 31 99.85 10 99.88 21 99.91 11 99.88 22 99.89

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com