Iron core and linear motor

A technology of linear motors and iron cores, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of affecting the performance of iron cores and low service life, and achieve the effects of improving product performance, reducing thickness, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

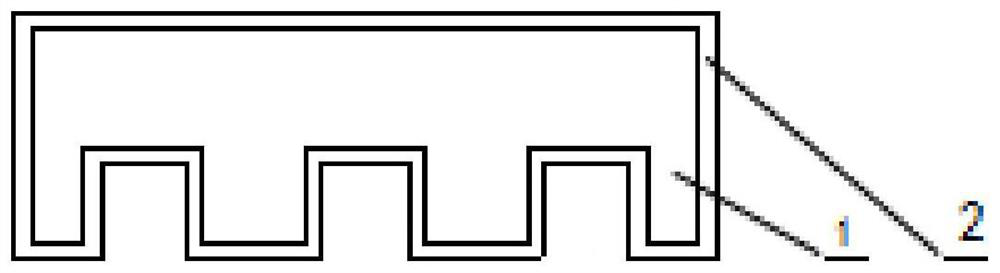

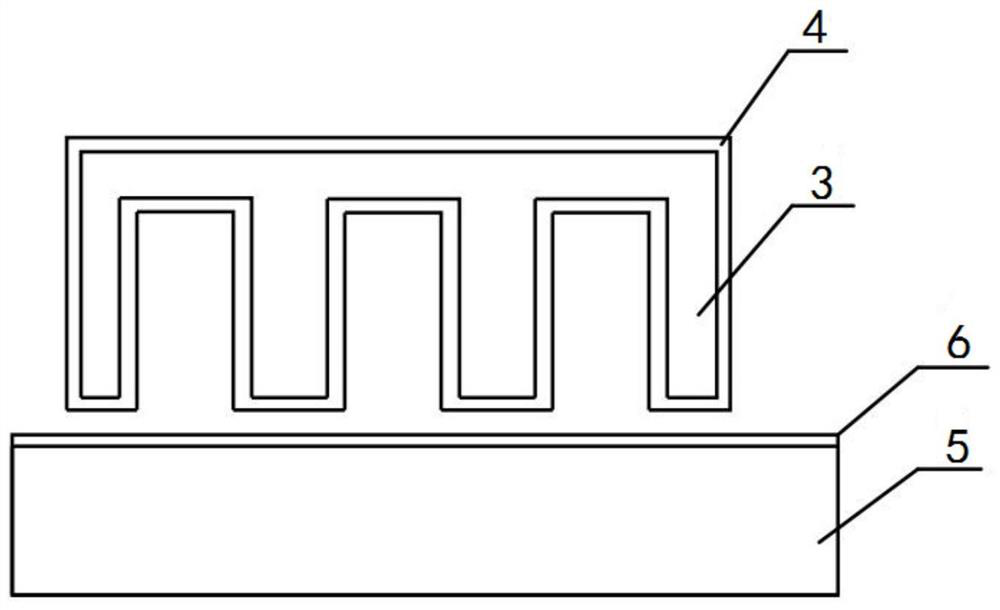

[0036] Using an amorphous strip as the iron core material 1, using a polyurea material as a solidified layer 2 on the outer surface of the amorphous strip, and the thickness of the solidified layer 2 is 0.5mm, to obtain an iron core;

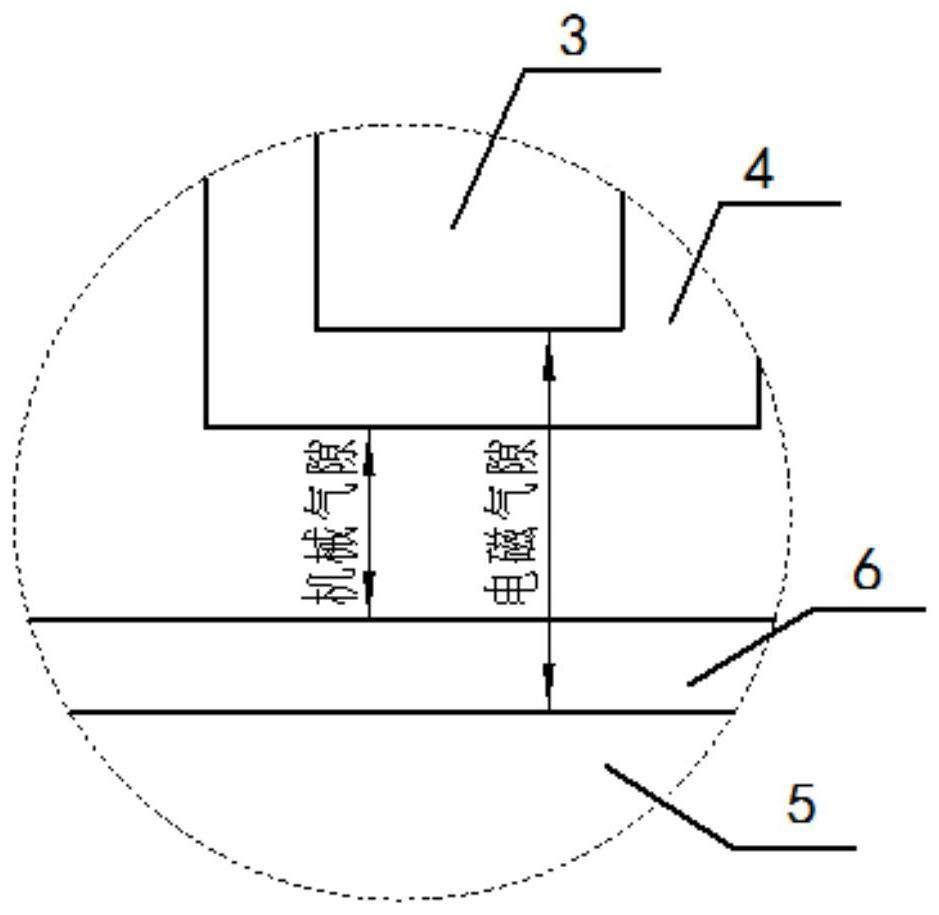

[0037] Use the above-mentioned iron core as the long stator of the linear motor, and ensure that the electromagnetic air gap of the linear motor is 11.5mm, and the mechanical air gap is 10mm;

[0038] The length of the long stator core is 1030mm, the height is 91.5mm, and the thickness is 175mm.

Embodiment 2

[0040] Using an amorphous strip as the iron core material 1, using a polyurea material on the outer surface of the amorphous strip as a solidified layer 2, and the thickness of the solidified layer 2 is 1mm, to obtain an iron core;

[0041] Use the above-mentioned iron core as the long stator of the linear motor, and ensure that the electromagnetic air gap of the linear motor is 12mm, and the mechanical air gap is 10mm;

[0042] Wherein, the external dimensions of the long stator core are the same as those of the long stator core in Embodiment 1.

Embodiment 3

[0044] Using an amorphous strip as the iron core material 1, using a polyurea material as a solidified layer 2 on the outer surface of the amorphous strip, and the thickness of the solidified layer 2 is 1.5 mm to obtain an iron core;

[0045] Use the above-mentioned iron core as the long stator of the linear motor, and ensure that the electromagnetic air gap of the linear motor is 12.5mm, and the mechanical air gap is 10mm;

[0046] Wherein, the external dimensions of the long stator core are the same as those of the long stator core in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com