Large-particle beef sauce and preparation method thereof

A beef paste and large-grain technology, which is applied in climate change adaptation, food science, etc., can solve the problems of not meeting the requirements of healthy diet, lack of grainy beef, and too spicy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A large-grain beef sauce, mainly comprising the following raw materials in parts by mass: 5000 parts of beef, 3000 parts of edible oil, 1500 parts of sauce, 2000 parts of pepper, 500 parts of garlic, 250 parts of ginger, 250 parts of onion, and 50 parts of white sugar 50 servings of white wine.

[0027] A kind of large particle beef sauce, its preparation method is as follows:

[0028] 1) Rinse the beef in running water with a pressure of 0.8atm and a water temperature of 42°C for 20 minutes to remove residual blood and other fishy substances in the raw beef;

[0029] 2) Prepare brine: add 50 parts of salt, 50 parts of monosodium glutamate, 100 parts of light soy sauce, 50 parts of dark soy sauce, 50 parts of oil consumption, 10 parts of fragrant leaves, 5 parts of star anise, 5 parts of cinnamon bark, 5 parts of grass fruit, cardamom 5 parts, 5 parts of Radix Paeoniae Alba, 10000 parts of water, heated and boiled for 15 minutes, then turned off the heat and cooled for...

Embodiment 2

[0035] A kind of large-grain beef paste, the specific preparation method is with reference to embodiment 1, difference is:

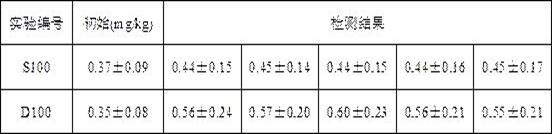

[0036] Step 1) Pretreatment uses the following pressures and flushing times, as shown in the table below.

[0037]

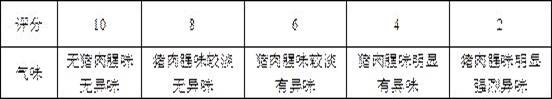

[0038] Carry out sensory evaluation on the beef pretreated in step 1) in Example 2, use filter paper to blot the grease and water on the surface of the beef block to be tested, and ask 8 evaluators to use the blind test method according to the scoring standard of smell sensory Sensory evaluation was performed on the beef pretreated in step 1) in Example 2 respectively.

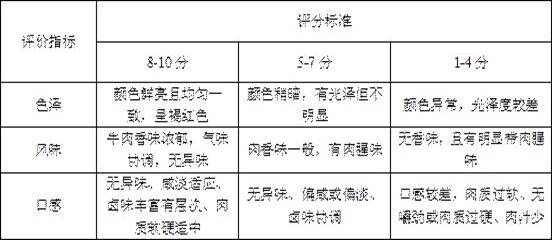

[0039] The sensory flavor evaluation invites 10 food major students and teachers with professional theoretical knowledge and rich experience to form a sensory evaluation team to judge and score from four aspects: texture, color, flavor, and taste. Keep the samples at room temperature during the test, randomly number the samples, and place them in disposable paper cups. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com