Deoxidation and isomerization catalyst and preparation method and application thereof

A catalyst and isomerization technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of temperature runaway, deactivation, bed heat transfer effect Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

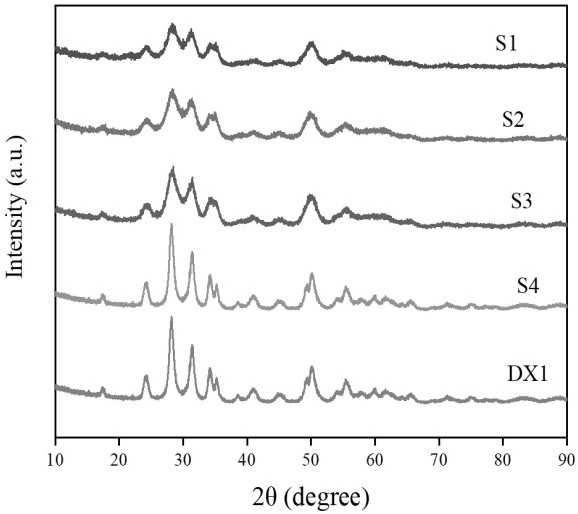

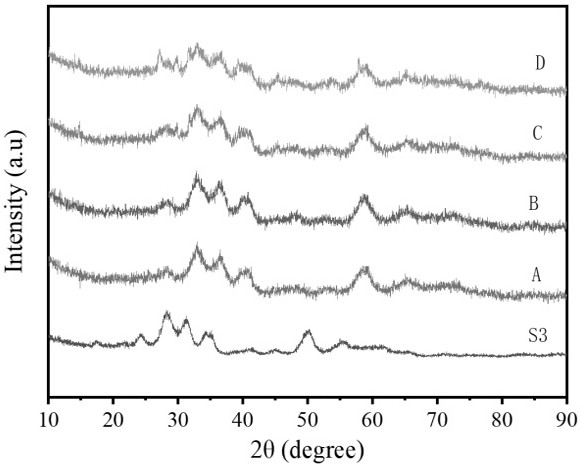

Image

Examples

Embodiment 1

[0034] The modification scheme described in this embodiment is prepared from the following raw materials:

[0035] Zirconium oxychloride, ZrOCl 2 ·H 2 o

[0036] Phosphoric acid, H 3 PO 4

[0037] 0.1mol / L ammonium molybdate tetrahydrate aqueous solution

[0038] where ZrOCl 2 ·8H 2 O, 41.8g, phosphoric acid is 4.84g, and the mass ratio of phosphorus to zirconium is 1:3.

[0039] Modification method described in the present embodiment is:

[0040] (1) Dissolving zirconium oxychloride in a certain amount of deionized water, and reacting in a hydrothermal kettle, the reaction temperature is 150° C., and the hydrothermal time is 6 hours.

[0041] (2) Add a certain amount of ammonia water to the product obtained after hydroheating in step (1) to make its pH value 8.8. The obtained white precipitate was centrifuged and washed. And dried at 110°C for 12h.

[0042] (3) Roast the product obtained in step (2) in a muffle furnace at 350°C for 4 hours, and cool to obtain the ...

Embodiment 2

[0049]The modification scheme described in this embodiment is prepared from the following raw materials:

[0050] Zirconium oxychloride, ZrOCl 2 ·H 2 o

[0051] Phosphoric acid, H 3 PO 4

[0052] 0.1mol / L ammonium molybdate tetrahydrate aqueous solution

[0053] where ZrOCl 2 ·8H 2 O, 41.8g, phosphoric acid is 2.91g, and the mass ratio of phosphorus to zirconium is 1:5.

[0054] Modification method described in the present embodiment is:

[0055] (1) Dissolving zirconium oxychloride in a certain amount of deionized water, and reacting in a hydrothermal kettle, the reaction temperature is 150° C., and the hydrothermal time is 6 hours.

[0056] (2) Add a certain amount of ammonia water to the product obtained after hydroheating in step (1) to make its pH value 8.8. The obtained white precipitate was centrifuged and washed. And dried at 110°C for 12h.

[0057] (3) The product obtained in step (2) was calcined in a muffle furnace at 450° C. for 4 hours and cooled to ob...

Embodiment 3

[0064] The modification scheme described in this embodiment is prepared from the following raw materials:

[0065] Zirconium oxychloride, ZrOCl 2

[0066] Phosphoric acid, H 3 PO 4

[0067] 0.1mol / L ammonium molybdate tetrahydrate aqueous solution

[0068] where ZrOCl 2 ·8H 2 O, 41.8g, phosphoric acid is 2.08g, and the mass ratio of phosphorus to zirconium is 1:7.

[0069] Modification method described in the present embodiment is:

[0070] (1) Dissolving zirconium oxychloride in a certain amount of deionized water, and reacting in a hydrothermal kettle, the reaction temperature is 150° C., and the hydrothermal time is 6 hours.

[0071] (2) Add a certain amount of ammonia water to the product obtained after hydroheating in step (1) to make its pH value 8.8. The obtained white precipitate was centrifuged and washed. And dried at 110°C for 12h.

[0072] (3) The product obtained in step (2) was calcined in a muffle furnace at 350° C. for 4 hours to obtain the carrier X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com