Control system of hydrostatic pressure compounding equipment for bimetal tube

A technology of hydraulic composite and bimetallic pipes, which is applied in the field of bimetallic pipe processing, can solve the problems of injury, inability to adjust, and danger of workers, and achieve the effects of ensuring safe production and improving processing accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in combination with the accompanying drawings in the examples of the present invention. The described embodiments are only part of the embodiments of the present invention, not all of them. The present invention can also be implemented in other ways than those described here, therefore, the protection scope of the present invention is not limited by the specific embodiments disclosed below.

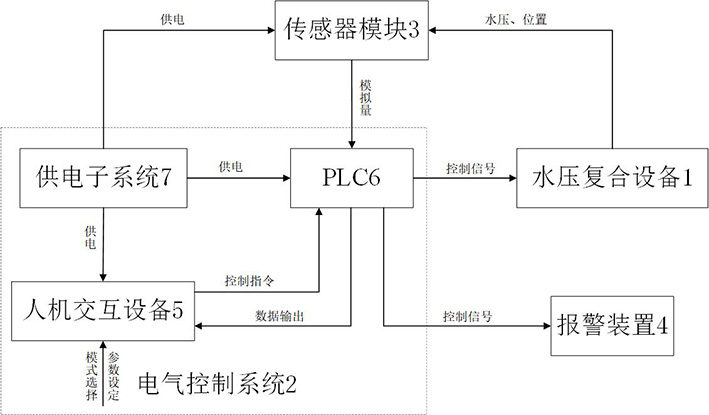

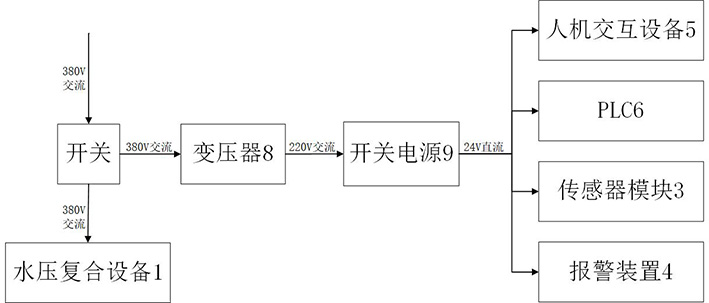

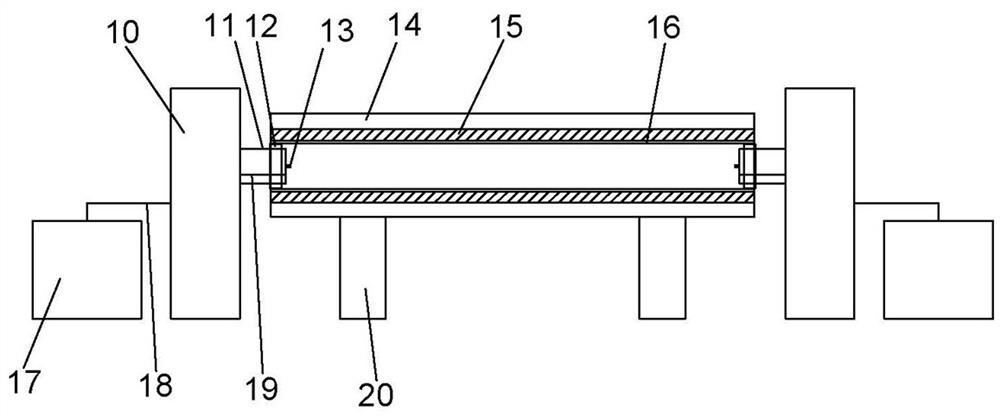

[0028] Such as Figure 1-3 As shown, a bimetallic tube hydraulic composite equipment control system includes hydraulic composite equipment 1, electrical control system 2, sensor module 3 and alarm device 4; hydraulic composite equipment 1 includes a hydraulic press 10, a stamping device 11, and a sealing device 12 and the mold group; the electrical control system 2 includes human-computer interaction equipment 5, PLC6 and power supply system 7; wherein the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com