Control method and control system for executing mechanism of garbage compression equipment

An executive mechanism and garbage compression technology, applied in presses, manufacturing tools, etc., can solve the problems that affect the efficiency of garbage compression treatment and transfer in garbage transfer stations, garbage compression equipment cannot operate normally, and position sensors are easily damaged, etc., to achieve The effect of flexible and convenient equipment debugging, reduced equipment investment cost, and reduced equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

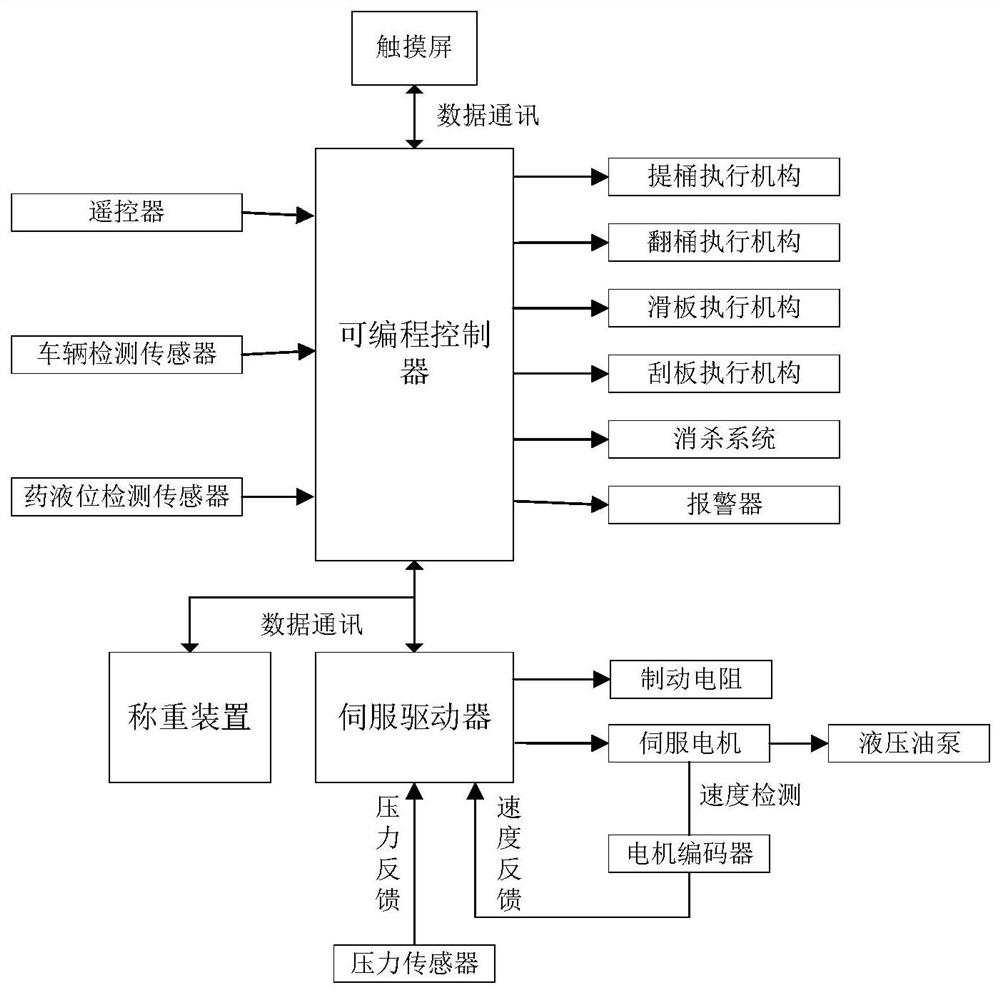

[0045] Such as figure 1 As shown, the control system of the garbage compression equipment includes an editable controller, touch screen, remote control, servo driver, servo motor, hydraulic oil pump, motor encoder, braking resistor, weighing device, pressure sensor, vehicle detection sensor, liquid medicine position detection sensor, bucket carrying actuator, bucket turning actuator, slide actuator, scraper actuator, disinfecting system, alarm; the programmable controller is the core device of the control system, and the logic control program and the logic control program of the control system are solidified Control Method. The Ethernet port of the programmable controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com