Full-anti-corrosion servo quantitative cylinder canning machine

A technology of quantitative cylinder and canning machine, which is used in packaging, liquid bottling, transportation and packaging, etc., can solve the problems of environmental pollution and volatilization of solutions in the operation room, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

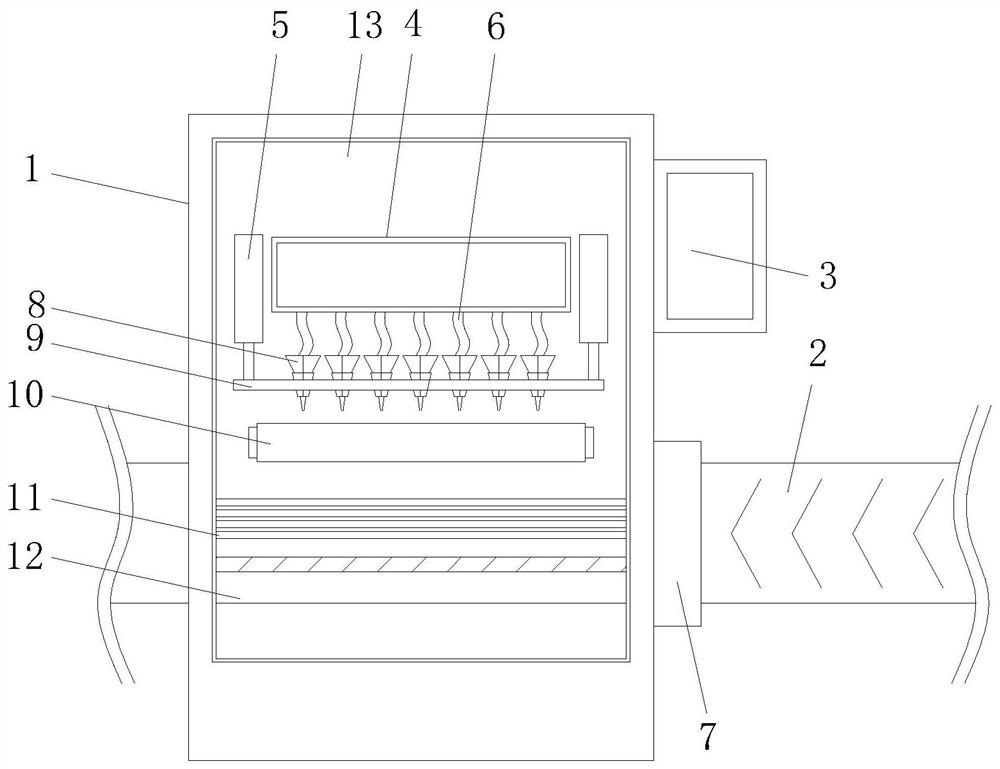

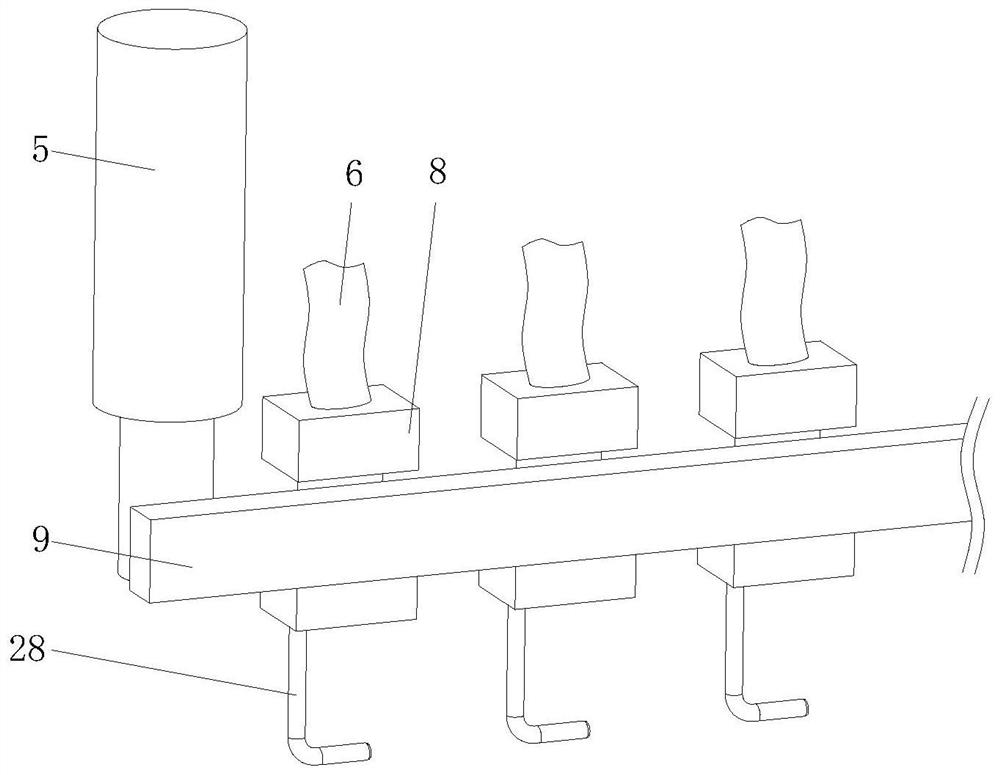

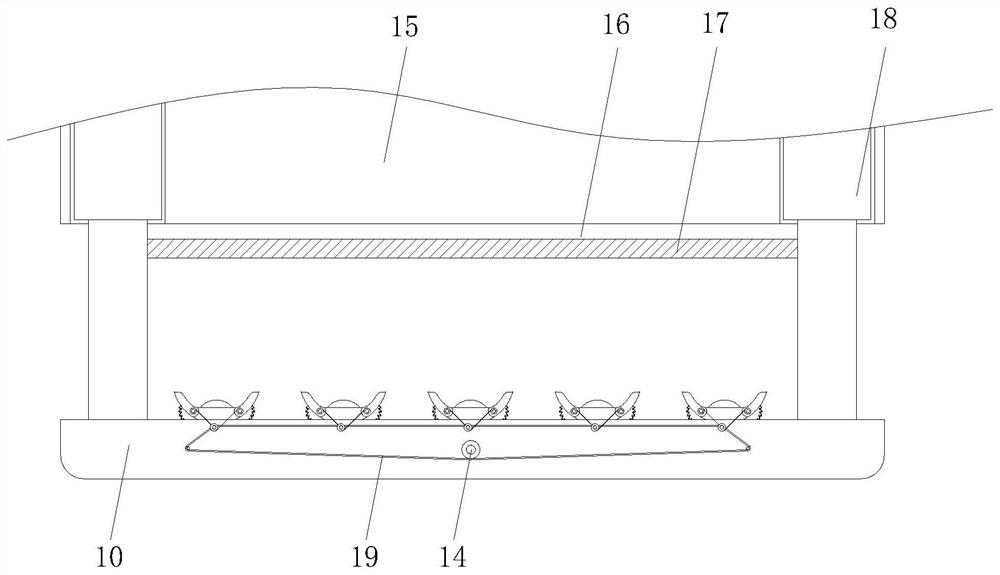

[0026] see Figure 1-5 As shown, the full anti-corrosion servo quantitative cylinder filling machine includes a sealing box 1; a protection box 2 is fixedly installed through one side of the sealing box 1, and a sealing Cover 7, the inner side of the protection box 2 is fixedly installed with a conveyor belt 12, the front end of the sealed box 1 is movably connected with a glass door 13, and the inner side of the protection box 2 is fixedly installed with two groups of hydraulic rods-5, the two groups of A connecting rod 9 is fixedly installed between the bottom ends of the hydraulic rod 1, and several groups of servo quantitative cylinders 8 are fixedly installed on one side of the connecting rod 9, and a transmission pipe 6 is fixedly installed on the top of the servo quantitative cylinder 8, The bottom end of the servo quantitative cylinder 8 is fixedly equipped with an adding pipe 28, and the inner side of the sealed box 1 is fixedly installed with a raw material box 4, an...

Embodiment 2

[0035] see Figure 6 As shown in Comparative Example 1, as another embodiment of the present invention, an exhaust fan 33 is fixedly installed on the top of the sealed box 1, and the bottom end of the exhaust fan 33 is connected to the inner side of the sealed box 1, and the exhaust fan 33 The bottom end is clamped with a filter cover 34; when working, start the exhaust fan 33 to discharge the air in the sealed box 1 outwards, cooperate with the setting of the filter cover 34 to purify the air, and prevent a large amount of corrosive gas from opening when the glass door 13 is opened. Spraying outwards, causing operator injury problems, further improves the safety of the device.

[0036] Working principle, when working, put the bottle to be filled on the conveyor belt 12 in the protective box 2, then start the conveyor belt 12, transport the bottle to the bottom of the servo quantitative cylinder 8 in the sealed box 1, cooperate with the setting of the guide rod 11, It can red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com