Efficient antibacterial textile material and production and preparation process thereof

A kind of textile material and high-efficiency technology, which is applied in the direction of processing textile material equipment configuration, processing textile material carrier, textile and paper making, etc. Not good and other problems to achieve the effect of avoiding mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] see Figure 1-10 It is a schematic diagram of the overall structure of a high-efficiency antibacterial textile material and the production and preparation process of the high-efficiency antibacterial textile material;

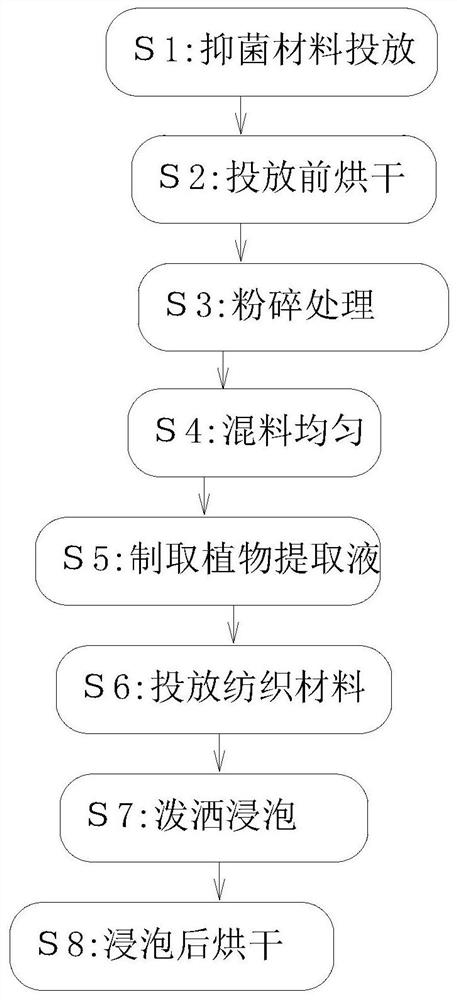

[0050] A method for producing and preparing an efficient antibacterial textile material, comprising the following steps;

[0051] S1. Putting antibacterial materials: put the plants with antibacterial and sterilizing functions into the pulverizer separately;

[0052] S2. Drying before putting in: drying each type of plant separately put in step S1, and putting the dried plants in the pulverizer;

[0053] S3, crushing treatment: each type of plant dried in step S2 is crushed, multiple types of plants are simultaneously put into the grinder for crushing or multiple types of plants are separated and then put into the grinder for crushing separately in sequence;

[0054] S4, uniform mixing: the crushed plants in step S3 fall down into the mixing barrel, an...

Embodiment 2

[0070] see Figure 10 It is the data result form of the present embodiment; the present embodiment has the similarity with the above-mentioned embodiment, and the similarity will not be elaborated again in the present embodiment, and the specific differences are:

[0071] A high-efficiency antibacterial textile material, which is formed by soaking plant extracts into the surface of the textile material and being absorbed by the textile material. The textile material is textile yarn or textile fabric, and the textile fabric is non-woven fabric, cotton cloth or fiber ;

[0072] The plant extract includes Angelica dahurica, Zanthoxylum bungeanum, Dandelion, Asarum, and Scutellaria baicalensis. The Angelica dahurica, Zanthoxylum bungeanum, Dandelion, Asarum, Scutellaria baicalensis, Artemisia argyi and Sophora baicalensis are first dried, and after drying, they are weighed and crushed according to parts by weight. Put 75% pure liquid alcohol to mix and extract the plant extract, ...

Embodiment 3

[0076] see Figure 1-9 It is a schematic diagram of the overall structure of a high-efficiency antibacterial textile material and the production and preparation process of the high-efficiency antibacterial textile material. This embodiment has similarities with the above-mentioned embodiments, and the similarities will not be described in this embodiment. The specific differences The advantage is that:

[0077] This embodiment has similarities with the above-mentioned embodiments, and the similarities will not be described in this embodiment. The specific differences are:

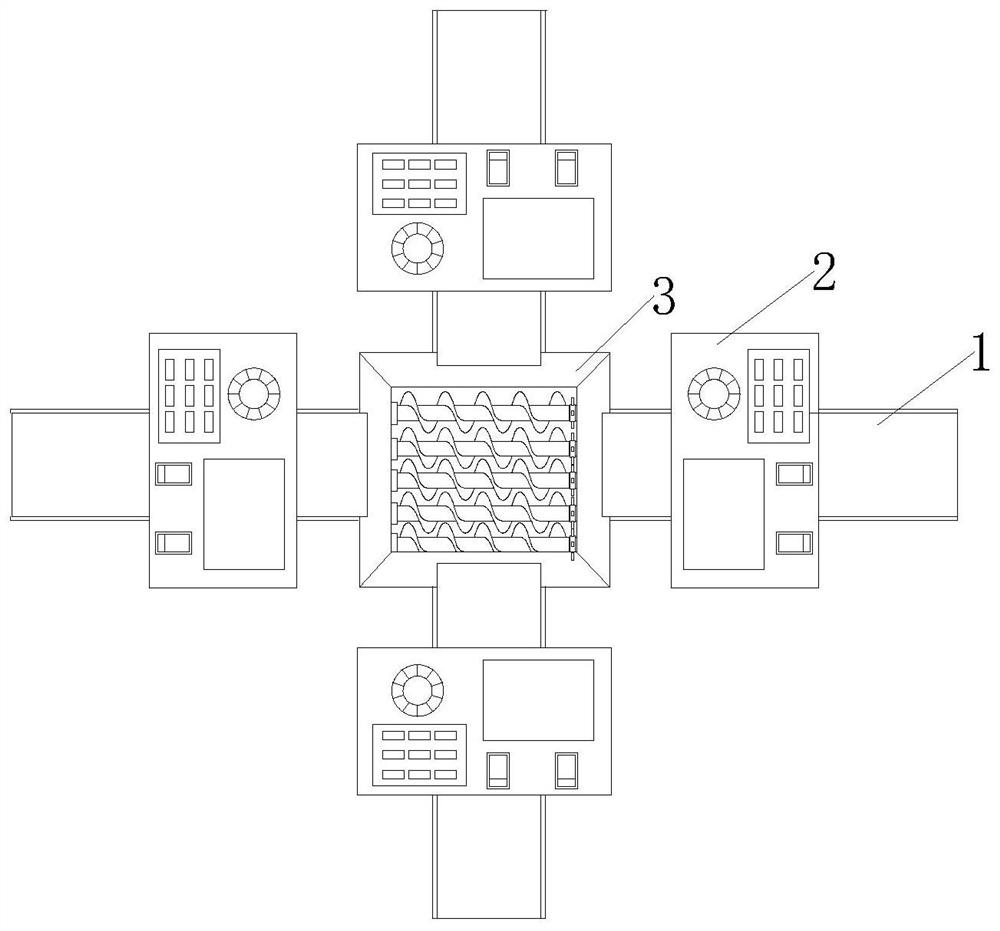

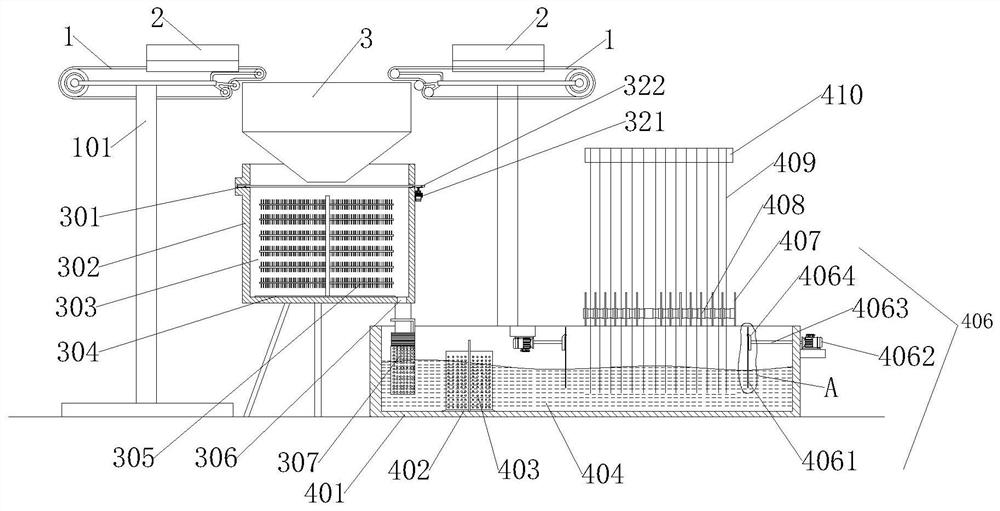

[0078] A high-efficiency antibacterial textile material production and preparation device includes a feeding belt 1, a drying box 2, and a pulverizer 3. There are a plurality of feeding belts 1, and a plurality of feeding belts 1 are arranged at equal intervals around the pulverizer 3. Each Each feeding belt 1 has an independent automatic conveying function, and the bottom end of each feeding belt 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com