Local superposed beam and prefabricated column node steel bar staggered connection structure and construction method thereof

A beam-column joint and superimposed beam technology, which is applied to building structures, structural elements, building components, etc., can solve problems such as low construction efficiency and poor seismic performance, so as to enhance seismic performance, reduce reinforcement work and concrete pouring amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

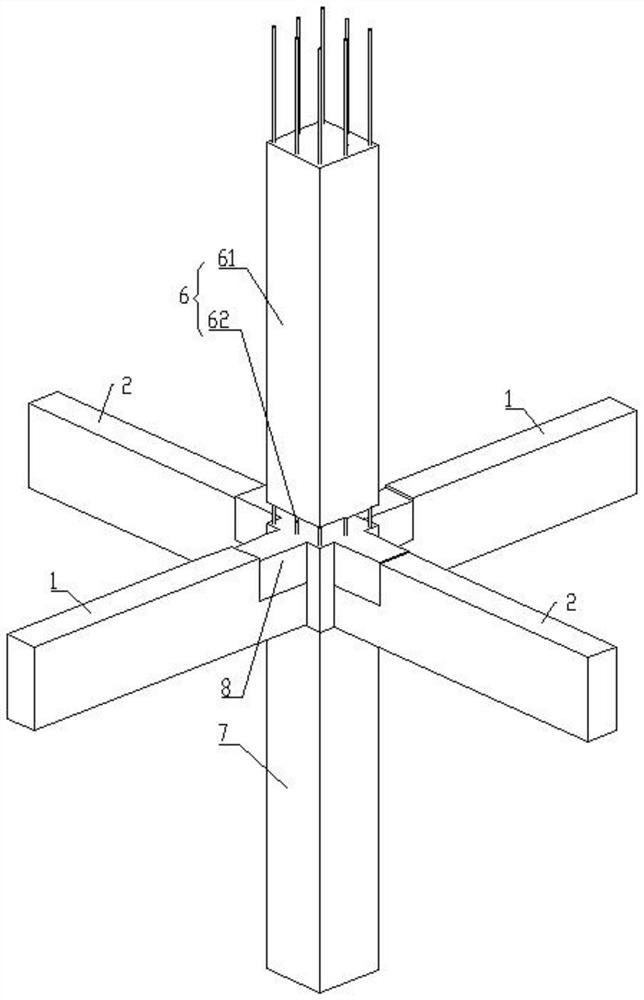

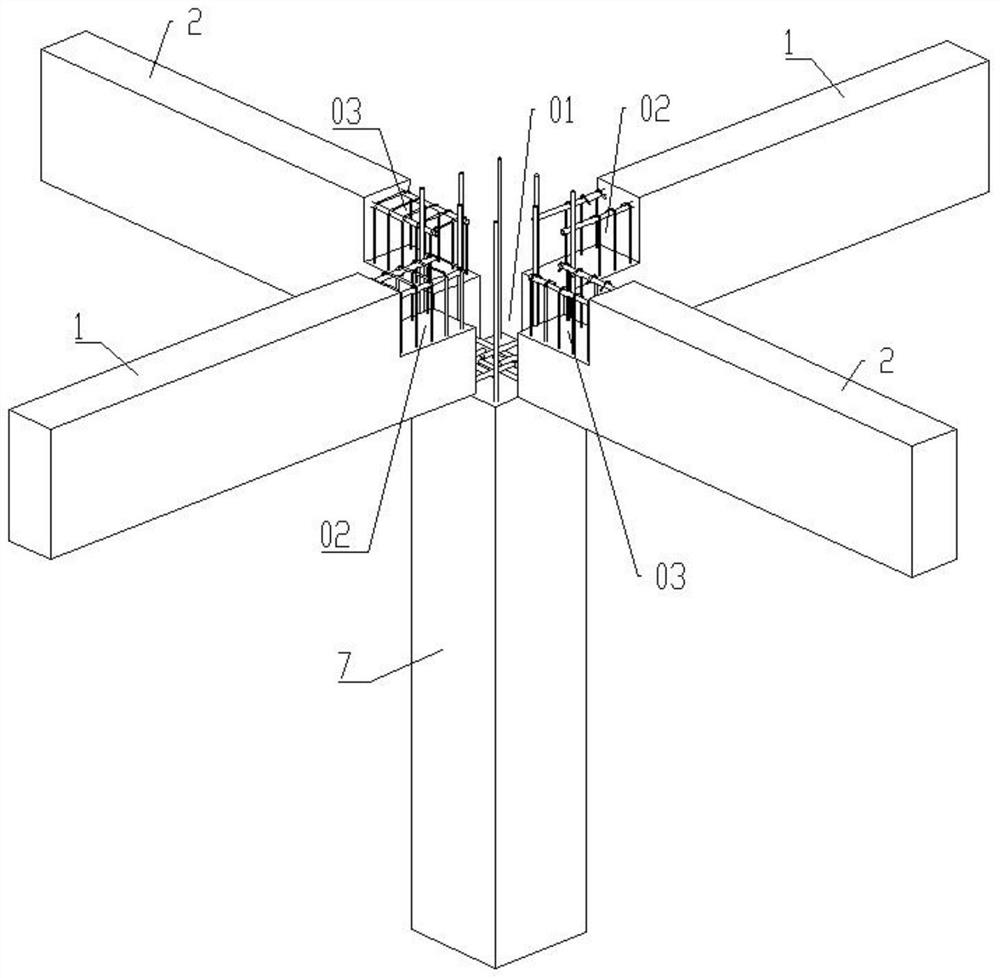

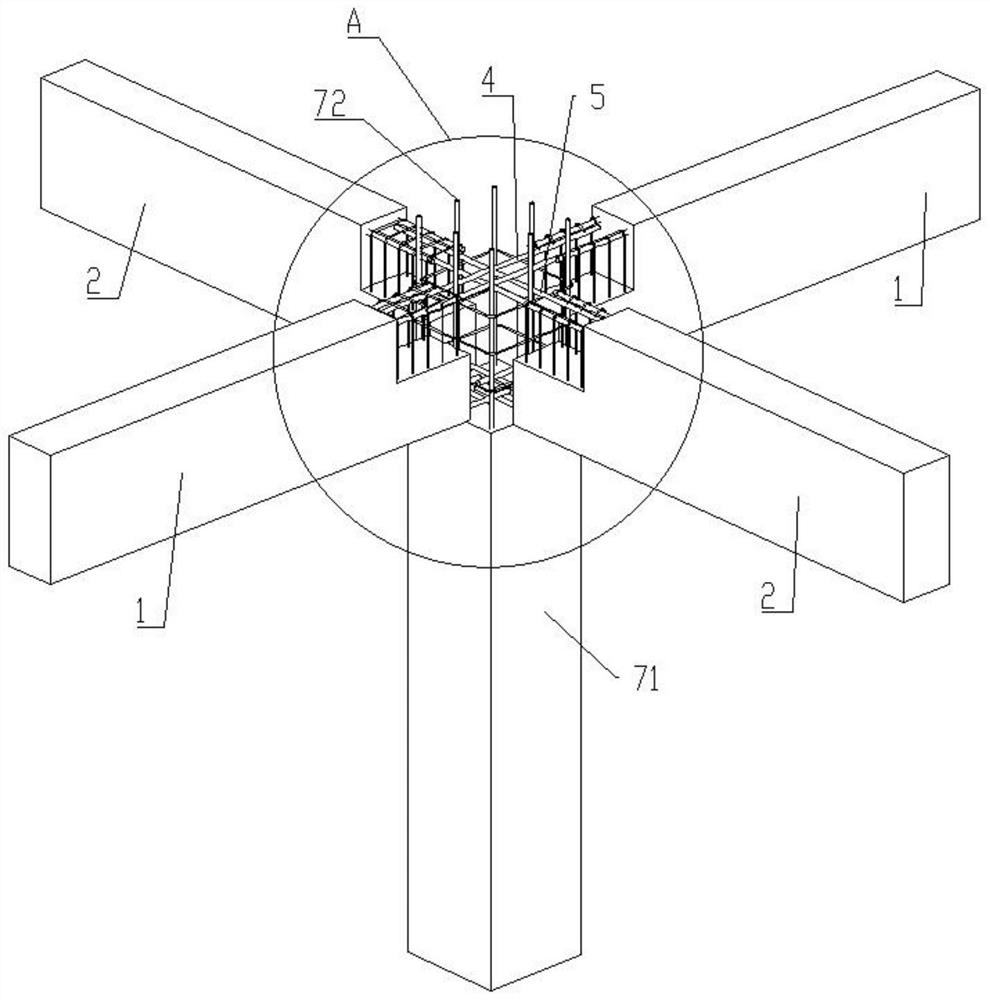

[0049] Please refer to the attached Figure 2-4 , a partial composite beam and prefabricated column joint reinforcement dislocation connection structure, including the prefabricated lower column 7 which is prefabricated by reinforced concrete, the first direction partial composite beam 1, the second direction partial composite beam 2, the prefabricated lower The column 7 includes a lower column main body 71 and a lower column longitudinal steel bar 72, the beam-column joint core area 01 is directly above the lower column main body 71, one end of the lower column longitudinal steel bar 72 is located in the lower column main body 71, and the other end of the lower column longitudinal steel bar 72 One end extends into the core area 01 of the beam-column joint; the partial laminated beam 1 in the first direction includes a first laminated body, and the first laminated body includes a first fully prefabricated beam section 11 and a beam located near the first fully precast beam sect...

Embodiment 2

[0062] The invention also discloses a construction method for the dislocation connection structure of local composite beams and prefabricated column nodes. The construction method of column node steel bar dislocation connection structure includes the following steps:

[0063] S1, making prefabricated components: complete the prefabrication of the prefabricated lower column 7, the partial composite beam 1 in the first direction, the partial composite beam 2 in the second direction, and the prefabricated upper column 6 according to the design requirements.

[0064] S2, hoisting the prefabricated lower column 7: hoist the prefabricated lower column 7 to the designed position by using a spreader, and install the prefabricated lower column 7.

[0065] During specific implementation, before hoisting the prefabricated lower column 7, it is necessary to measure and set out the line to determine the specific position of the component, correct the position of the longitudinal steel bar ...

Embodiment 3

[0073] The invention also discloses a construction method for the dislocation connection structure of local composite beams and prefabricated column nodes. The construction method of column node steel bar dislocation connection structure includes the following steps:

[0074] S1, making prefabricated components: complete the prefabrication of the prefabricated lower column 7, the partial composite beam 1 in the first direction, the partial composite beam 2 in the second direction, and the prefabricated upper column 6 according to the design requirements.

[0075] S2, hoisting the prefabricated lower column 7: hoist the prefabricated lower column 7 to the designed position by using a spreader, and install the prefabricated lower column 7.

[0076] S3, hoisting the partial laminated beam 1 in the first direction: measuring and setting out, placing the support of the partial laminated beam, hoisting the partial laminated beam 1 in the first direction to the corresponding position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com