Semi-outdoor colored terrace construction method

A construction method and floor technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve the problems of separation of colored polyurethane floors, low maintenance costs, color fading, etc., and achieve ground strength. High, reduced maintenance costs, improved wear and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

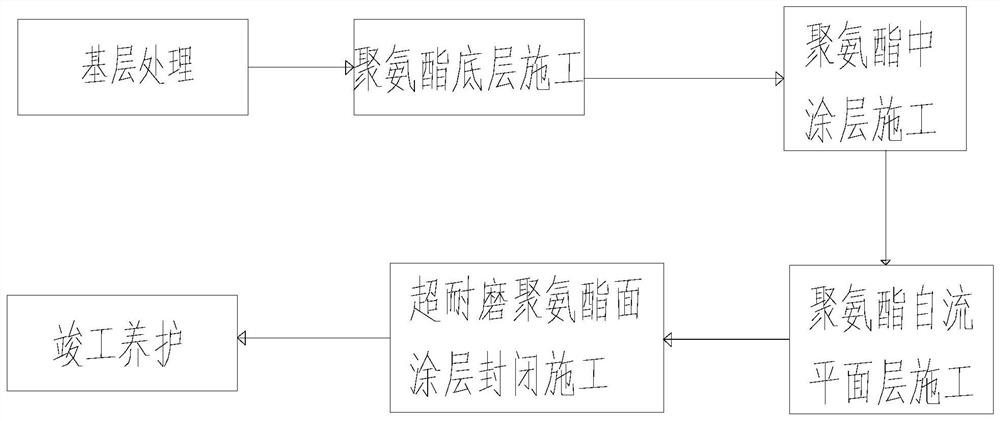

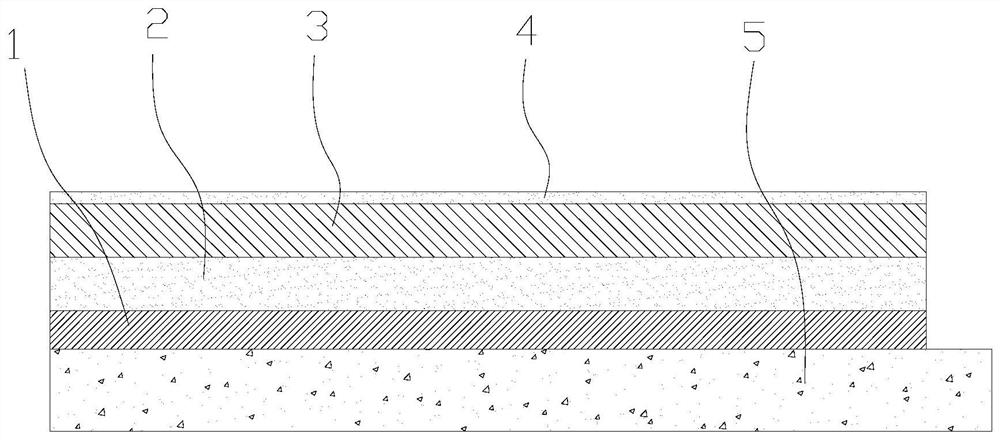

[0026] Such as figure 1 with figure 2 As shown, a semi-outdoor color floor construction method, the construction method process includes,

[0027] S1, base layer 5 treatment, first use a grinder to grind the ground, use a hand-held angle grinder at the corners to grind all the surface of the floor tiles, and then use a small manual cutter to cut out the gaps between all the original floor tiles The depth and width of the gap are twice the thickness of the floor system, and the width is the same as that of the original tile mosaic seam. Finally, the polyurethane material is used to fill up the cut seam;

[0028] When treating the base layer 5, clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com