Cable bent tower beam light-weight support design and construction method

A design method and lightweight technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as unreasonable structural design of beam support, large design load, waste of resources, etc., and achieve a wide range of applications. , Improve safety and ensure the effect of design accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

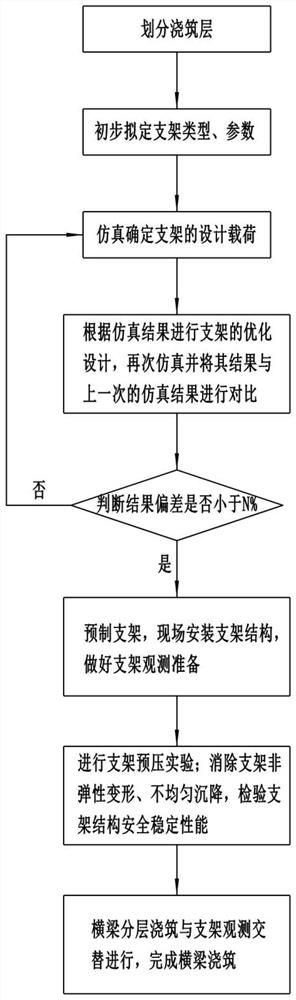

[0031] The specific steps of the design method of the present embodiment are:

[0032] Step 1, dividing each pouring layer of the cable tower beam and determining the height of each pouring layer, the present embodiment divides the horizontal beam into two layers of equal height;

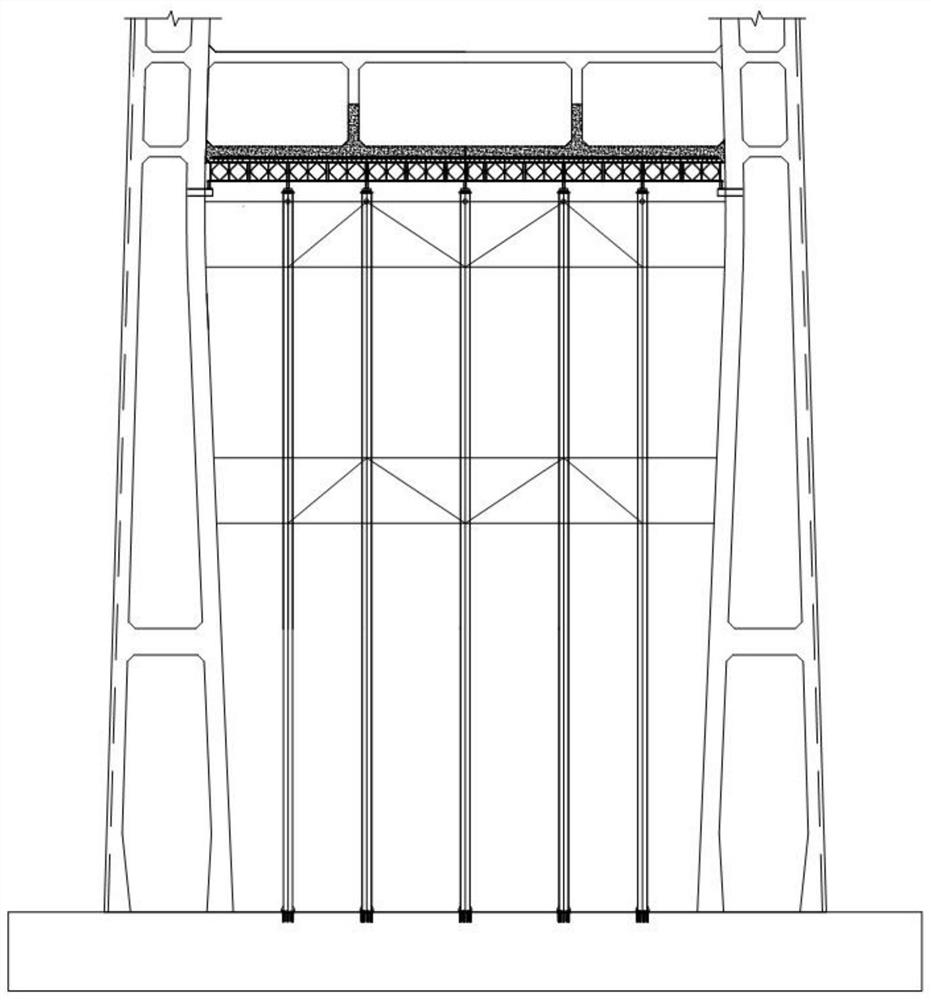

[0033] Step 2: Preliminarily draw up the structural form of the beam support, the type and parameters of the support section according to the division results of step 1; the tentative value Q=Q1+Q2*A% of the design load of the preliminary design of the beam support, where Qi is the i-th For the weight of concrete layered by layer, the proportion value A% is 60%; with Q as the tentative design load, the preliminary design of parameters such as the support structure form and support section type is carried out in combination with the spatial position and type of the beam. The preliminary design of this embodiment is floor-standing Steel pipe support;

[0034] Step 3, use the simulation software to si...

Embodiment 2

[0043] The specific steps of the design method of the present embodiment are:

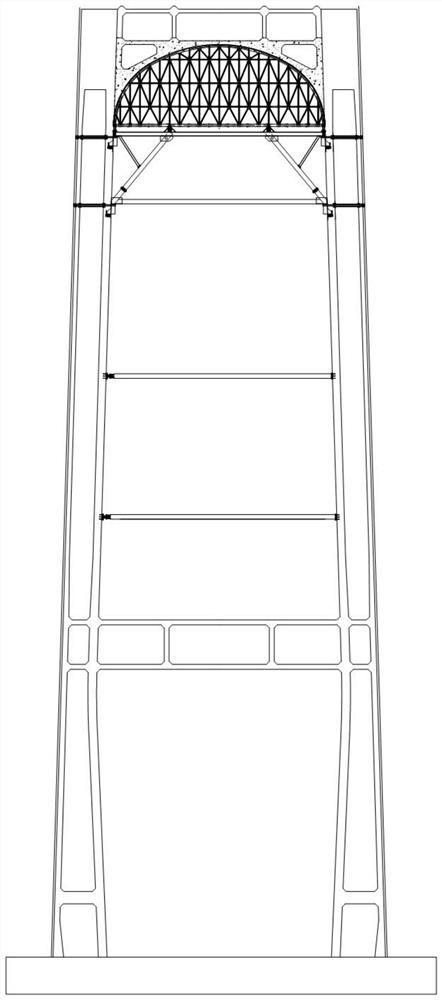

[0044] Step 1: Divide each pouring layer of the cable tower beam and determine the height of each pouring layer. In this embodiment, the arc-shaped beam is divided into four layers, and the first three layers of beams are closed after pouring is completed. Therefore, Q1 in the original equation should be The sum of the quality of the first three layers of concrete in the present embodiment;

[0045] Step 2: Preliminarily draw up the structural form of the beam support, the type and parameters of the support section according to the division results of step 1; the tentative value Q=(Q1+Q2+Q3)+Q4*A% of the design load of the preliminary design of the beam support , the proportional value A% is taken as 60%; with Q as the tentative design load, the preliminary design of parameters such as the support structure form and the support section type is carried out in combination with the spatial position an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com