Online sensing method for spinning forming state

A spinning forming, state technology, applied in the direction of instrument, design optimization/simulation, electrical digital data processing, etc., can solve the problems of high surface quality requirements, difficult application, inability to meet, etc., to improve the degree of intelligence, reduce flange The degree of fluctuation, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

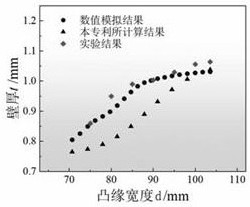

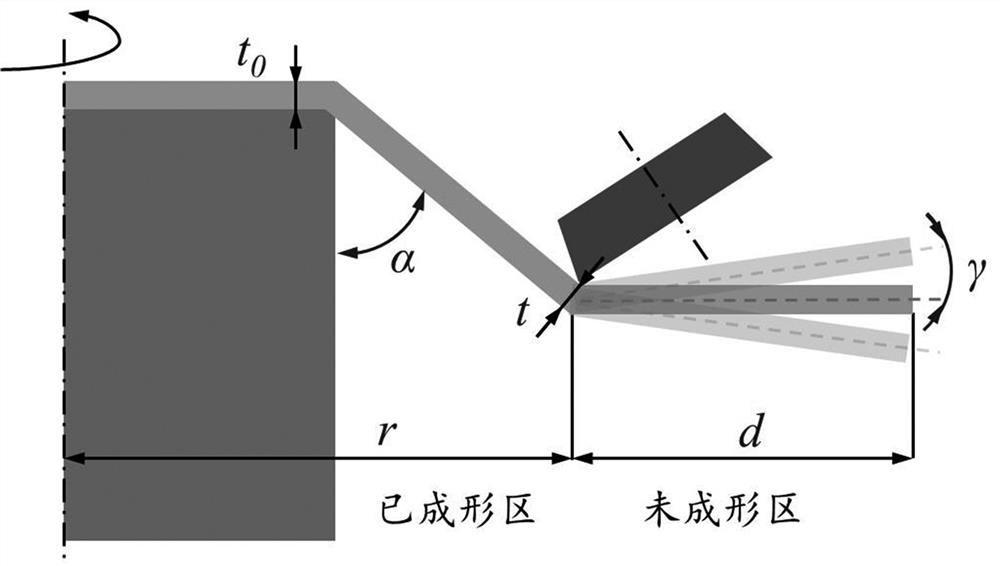

[0042] Example 1 Derivation of Instantaneous Normalized Thinning Rate Formula for Curved Surface Parts

[0043] This embodiment proposes a new mathematical formula that can directly predict the instantaneous normalized thinning rate of curved surface parts, using the radius r of the wheel 2, the width of the flange d, the elastic modulus E of the blank 1, and Poisson's ratio μ4 The key parameters in the spinning forming process can be used to calculate the normalized thinning rate of curved surface parts at a certain moment in the spinning forming process. The specific derivation process of the formula is as follows:

[0044] 1. Determination of important geometric parameters of instantaneous configuration of curved surface parts

[0045] During the spinning forming process of curved surface parts, the workpiece is mainly divided into two areas, the formed area and the unformed area. The unformed area is the flange part, and the flange width characteristics are constantly ch...

Embodiment 2

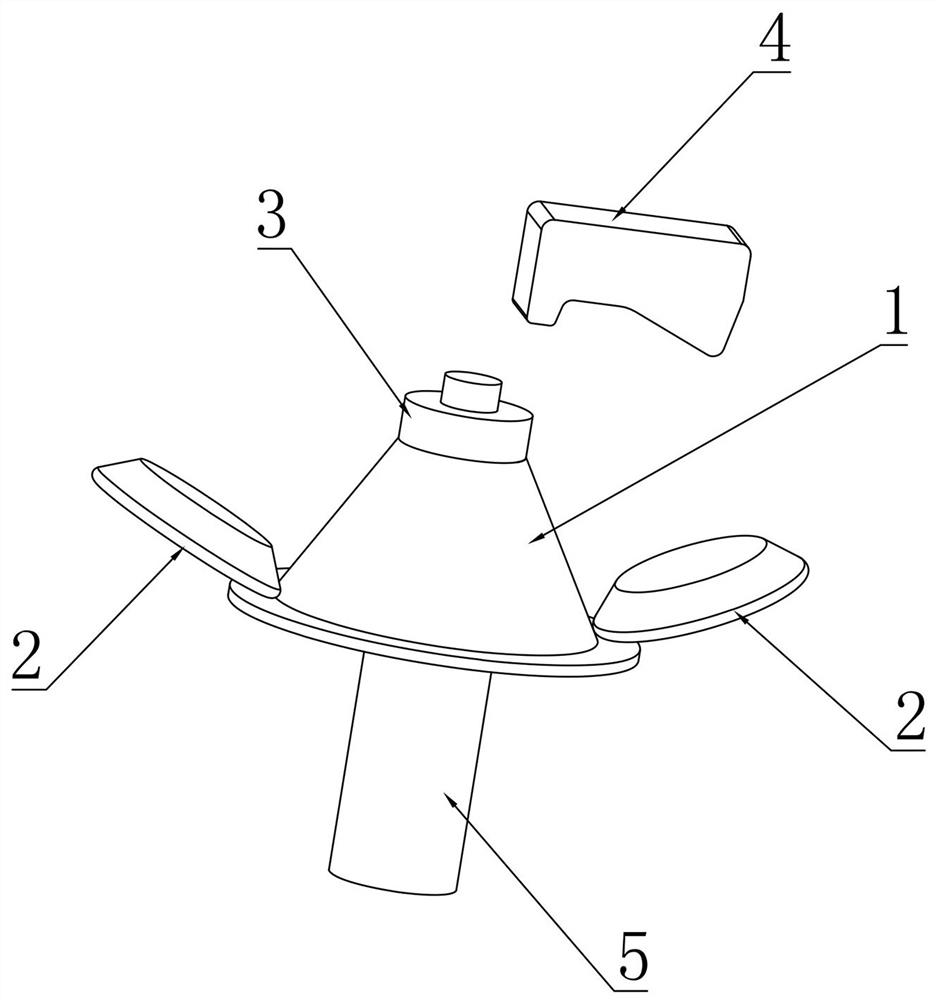

[0068] Embodiment 2 An online sensing method for spinning forming state

[0069] This embodiment obtains the instantaneous configuration of the curved surface part based on the laser scanner 4, and extracts two geometric parameters characterizing the instantaneous configuration of the curved surface part, the action radius r of the wheel 2 and the flange width d; the elastic modulus of the blank 1 is obtained from the unidirectional tensile test. Quantity E and Poisson's ratio μ two material parameters; According to these four parameters combined with the formula 1 in the embodiment 1, the instantaneous normalized thinning rate of the curved surface piece is predicted On this basis, according to the formula 2 in Embodiment 1, the spinning forming state of the curved surface part is judged, and then the online perception of the spinning forming state of the curved surface part is realized.

[0070] like Figure 4 As shown, this implementation includes the following steps, whe...

Embodiment 3

[0081] Embodiment 3 An online sensing method for spinning forming state

[0082] In this embodiment, taking the spinning process of a curved surface piece with a radius of blank 1 of 110mm, a thickness of blank 1 of 1mm, a radius of mandrel 5 of 45mm, and a half-cone angle α of the rotary wheel 2 of 50° as an example, the state of the curved surface piece at a certain moment of spinning judge. Among them, the material of blank 1 is 1060 aluminum alloy, and the initial flange width d 0 =65mm, initial blank 1 thickness t 0 = 1mm. The specific steps are as follows:

[0083] Step S1, install a laser scanner 4 on the upper side of the blank 1 in the machine tool, and ensure that: a, the laser line of the laser scanner is parallel to the direction of the main axis of the machine tool; b, the vertical distance between the laser scanner 4 and the blank 1 is 280-290mm , The vertical distance between the laser scanner 4 and the spindle of the machine tool is 38-43mm.

[0084] In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com