Plum cake production line with integrated functions of cleaning, denucleating, flavoring, drying and forming

A production line and integrated technology, which is applied in fruit de-pitting devices, confectionery, confectionery industry, etc., can solve the problems of tools that are easy to damage the human body, high labor costs, slow de-nucleating speed, etc., to achieve convenient extraction, speed up efficiency, improve The effect of the speed of denucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

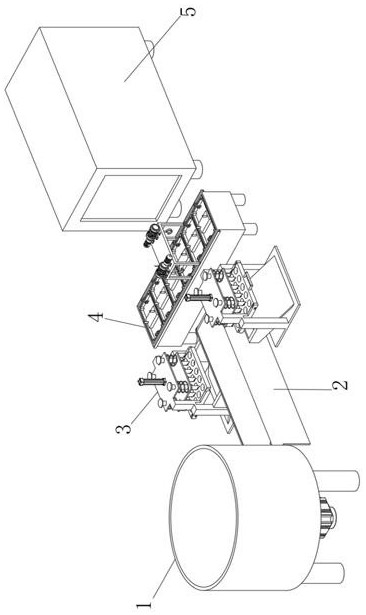

[0048] see Figure 1-Figure 6As shown, there is provided a plum cake production line with integrated functions of cleaning, de-pitting, flavoring, drying and forming, which sequentially includes a cleaning and mixing bucket 1 for cleaning the plums, a conveyor belt 2 for transporting the plums, and a conveyor belt for transporting the plums. A pitting device 3 for removing the pits of plum fruits, a pickling device 4 for pickling and tasting plums, and a drying device 5 for drying and shaping the pickled plums;

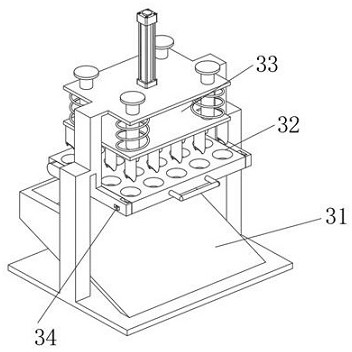

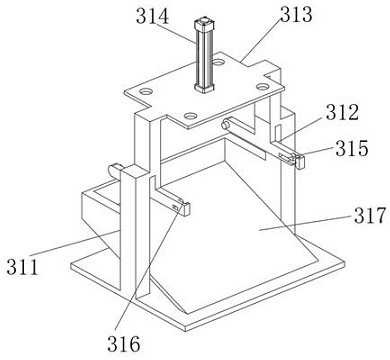

[0049] The coring device 3 includes a mounting frame 31 and a receiving device 32 and a stamping device 33 arranged on the mounting frame 31. The mounting frame 31 includes two support rods 311 whose bottoms are fixedly connected with a placement plate, and between the two support rods 311 is close to the middle The position is fixedly connected with a connecting plate 312, and the tops of the two support rods 311 are fixedly connected with a top plate 313, on which a...

Embodiment 2

[0056] refer to Figure 7-Figure 10 , the pickling device 4 comprises a holding device 41 for holding marinade, and the inside of the holding device 41 is provided with several filling devices 42 for holding plum fruit, and the inside of the holding device 42 is provided with The material pressing device 43 that dialogue plum fruit is pressed.

[0057] The holding device 41 includes a pickling bucket 411 and several dividers 412 fixed on the inner wall of the pickling bucket 411 to divide the inside of the pickling bucket 411 into a plurality of pickling chambers, the bottom of the divider 412 and the pickling bucket The bottom of 411 does not touch, and material holding device 42 comprises material holding frame 421 and the material retaining net 422 that is installed on the material holding frame 421 sidewall, and material holding frame 421 is arranged in the marinating cavity separated by dividing plate 412, sets A plurality of material holding devices 42 undertakes the ye...

Embodiment 3

[0061] In order that pickled Huangmei fruit is taken out from the holding device 41, refer to Figure 9-Figure 11 , the upper side of the bearing device 41 is provided with a lifting device 44, the lifting device 44 includes a lifting frame 441 fixedly connected with moving wheels 445 at the four corners of the bottom, and the two ends of the upper side of the lifting device 44 are provided with winch racks 442 And the motor 443 that is used to drive the rotation of the winch frame 442, the fiber rope is wound on the winch frame 442, and one end of the fiber rope is connected with a hook 444, and the two ends on the upper side of the material holding frame 421 and the pressure plate 431 are fixedly connected with a puller respectively. The ring 424, the pull plate 433, and the hook 444 are hooked up with the pull ring 424 and the pull plate 433 respectively. The sides of the pickling barrel 411 close to the top are fixedly connected with the sideslip track 413, and the moving w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com