Dry and wet coal layered treatment automatic dust falling device and using method thereof

A dust suppression device, dry and wet technology, applied in the direction of separation methods, combined devices, chemical instruments and methods, etc., can solve problems affecting the health of workers, dust accumulation and blockage, and reduced production efficiency, so as to improve efficiency and reduce dust removal Cost, Effect of Avoiding Splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

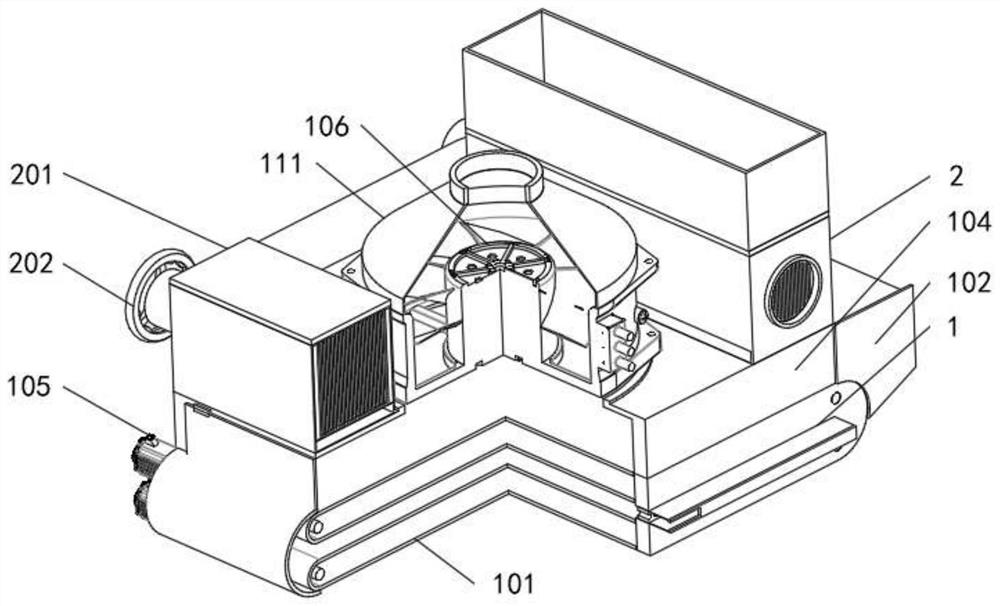

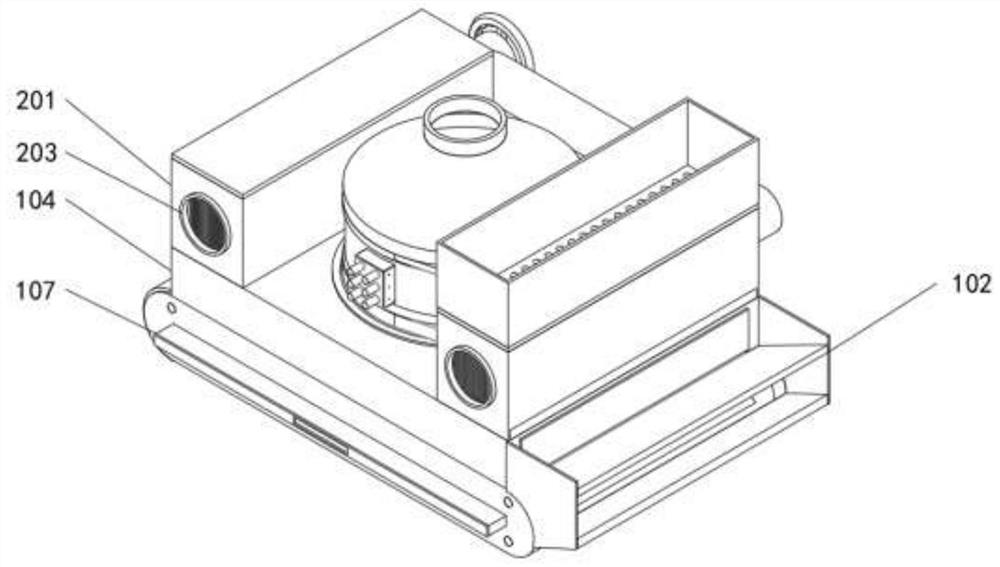

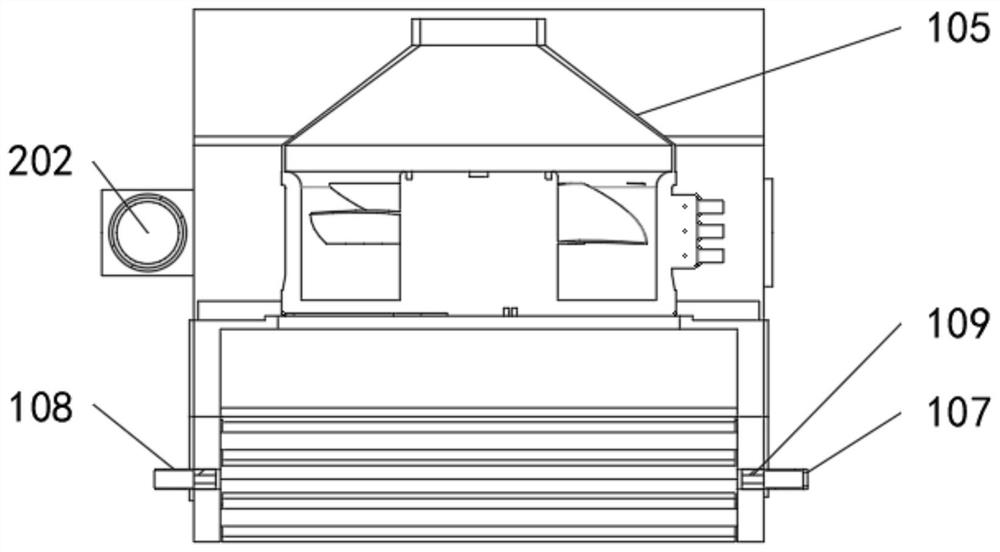

[0034] Embodiment one, with reference to Figure 1 to Figure 10 : An automatic dedusting device for dry and wet coal layered treatment, including a transport structure 1 and a dust removal structure 2, the transport structure 1 includes two conveyor belts 101, a feeding baffle 102, a sealing plate 103, a sealing shell 104, a negative pressure fan 106 and a sealing Blocking plate 110, two conveyor belts 101 are set up and down through the bracket, and the two conveyor belts 101 are installed through the bracket to ensure the vertical alignment, and assist the sealing shell 104 to realize the sealing of the conveyor belt 101, and the feeding baffle 102 is installed at one end of the conveyor belt 101 , the sealing plate 103 is hingedly arranged on the inner wall of the feeding baffle 102, the sealing plate 103 can prevent dust from splashing out from the feeding position, and ensure the air quality of the working environment. The sealing shell 104 is fixedly arranged on the top o...

Embodiment 2

[0035] Embodiment two, refer to Figure 1 to Figure 10: the top of the outer wall of the negative pressure fan 106 is connected with a concentrating pipe 111 through bolts, and the top of the concentrating pipe 111 is connected to the input end of one of the connecting pipes 203 through a flexible pipe, and the top of the outer wall of one of the treatment boxes 201 is fixedly provided with a water tank 204, the bottom of the inner wall of the two treatment boxes 201 is embedded with a collection box 208, through the collection box 208, waste water and dust can be collected, and the collection box 208 is connected to the input end of the water tank 204 through a booster pump, and the water tank 204 A plurality of dust removal holes 205 are equidistantly opened at the bottom of the inner wall, and the bottom ends of the plurality of dust removal holes 205 are connected to the top of the treatment box 201. The outer walls of the two conveyor belts 101 are embedded with porous pla...

Embodiment 3

[0036] Embodiment three, refer to Figure 1 to Figure 10 : a kind of using method of dry and wet coal stratification processing automatic dust suppression device, has used a kind of dry and wet coal stratification processing automatic dust suppression device according to any one in claim 1-9, comprises: step 1, at first utilizes feeding block Board 102 puts dry and wet coal onto the conveyor belt 101 respectively, dry coal is put into the upper conveyor belt 101, and wet coal is put into the top of the outer wall of the lower conveyor belt 101. 104 forms a sealed framework. Through step 1, it is possible to carry out layered treatment of coal, complete the sealing treatment before dust removal, and avoid dust splashing. Step 2, open the conveying pipeline, start the negative pressure fan 106, and absorb dry powdery dust , transported to the inside of the processing box 201, the airflow carrying the dust passes through the grid plate 206 wetted by the water tank 204 to complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com