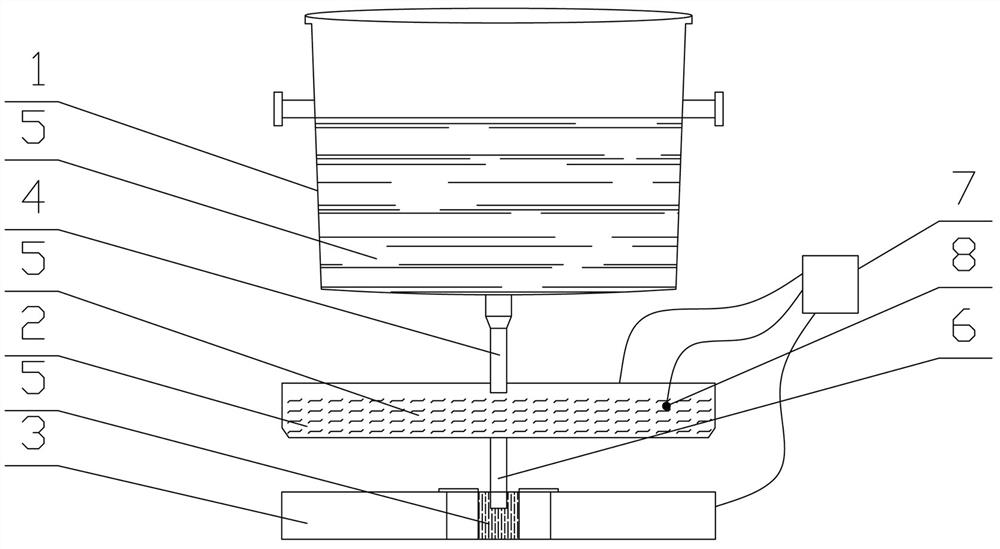

Automatic slag line changing system of slab caster based on molten steel temperature control

A slab continuous caster and molten steel temperature technology, which is applied in the field of iron and steel metallurgy, can solve the problems of slag entrainment on the liquid level of the mold, longitudinal cracks on the surface of the slab, and the influence of the quality of the slab without considering the insertion depth of the submerged nozzle. The effect of cost saving and reduction of longitudinal crack ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

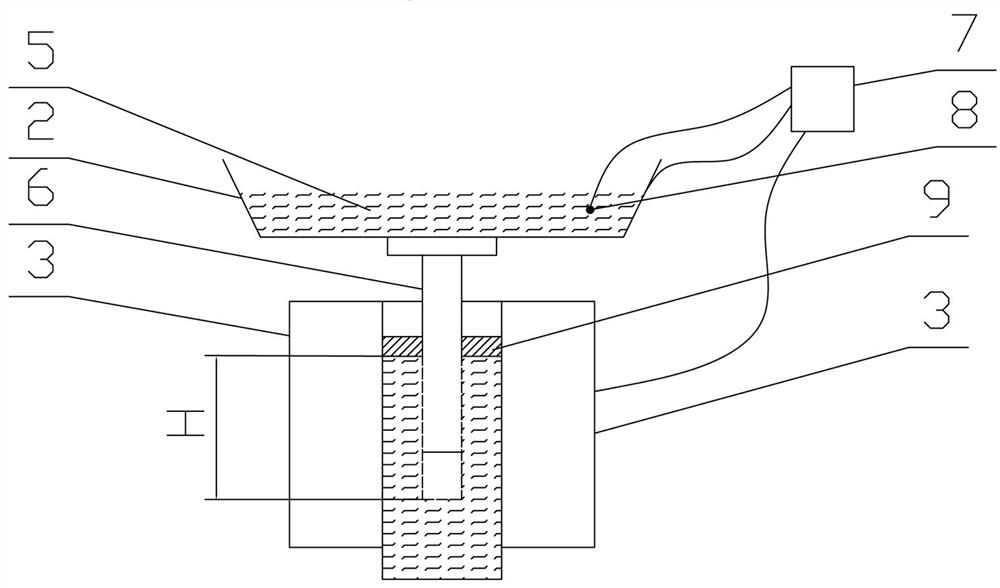

[0031] The automatic slag-changing line system of the slab continuous casting machine in this embodiment based on the temperature control of molten steel is the same as that in Embodiment 1. In this embodiment, the 45 steel with a specification of 300mm*2000mm produced by the slab continuous casting machine is taken as an example, and the liquidus temperature of the steel is 1492°C, the control steps are:

[0032] (1) The steel grade selected to be produced in the primary machine system of the continuous casting machine before pouring is 45 steel;

[0033] (2) Set the superheat range corresponding to the insertion depth range of the submerged nozzle:

[0034] Superheat range ℃ 10~15 15~25 25~35 Insertion depth mm 100~120 120~140 140~160

[0035] (3) The casting machine starts pouring, and the molten steel fills the tundish;

[0036](4) After the pouring starts normally, start the continuous temperature measurement of molten steel in the tundish, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com