Cylindrical surface hole forming equipment

A cylindrical surface and hole-forming technology, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring/drilling, etc., can solve the problems of prolonging the production cycle cost of parts, and achieve saving of processing procedures, simple structure, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

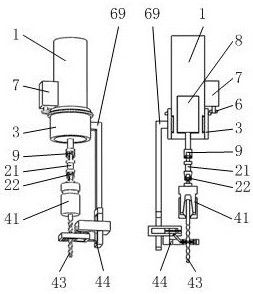

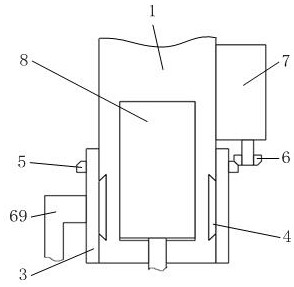

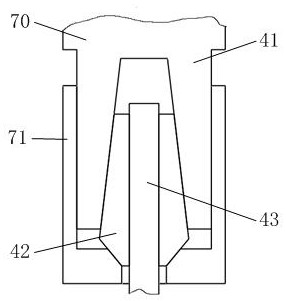

[0039] Such as figure 1 , 2 As shown, it includes mechanical arm 1, electric drive module A7, ring sleeve A3, L rod 69, electric drive module B8, universal joint mechanism A9, connecting rod 21, universal joint mechanism B22, drill bit fixture 41, vibration elimination mechanism 44, where if figure 1 , 3 As shown, the end of the output shaft of the electric drive module B8 installed in the end of the mechanical arm 1 is equipped with a connecting rod 21 through the universal joint mechanism A9, and the connecting rod 21 is equipped with a drill bit for clamping the twist drill bit 43 through the universal joint mechanism B22 Fixture 41; as Figure 6 , 10 As shown, both the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com