Novel superposition process for rock plate surface decoration and rock plate

A technology for surface decoration and slate, applied in the field of architectural ceramics, can solve the problems of complex equipment, low quality rate, high equipment price, etc., and achieve the effect of stable production and low equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

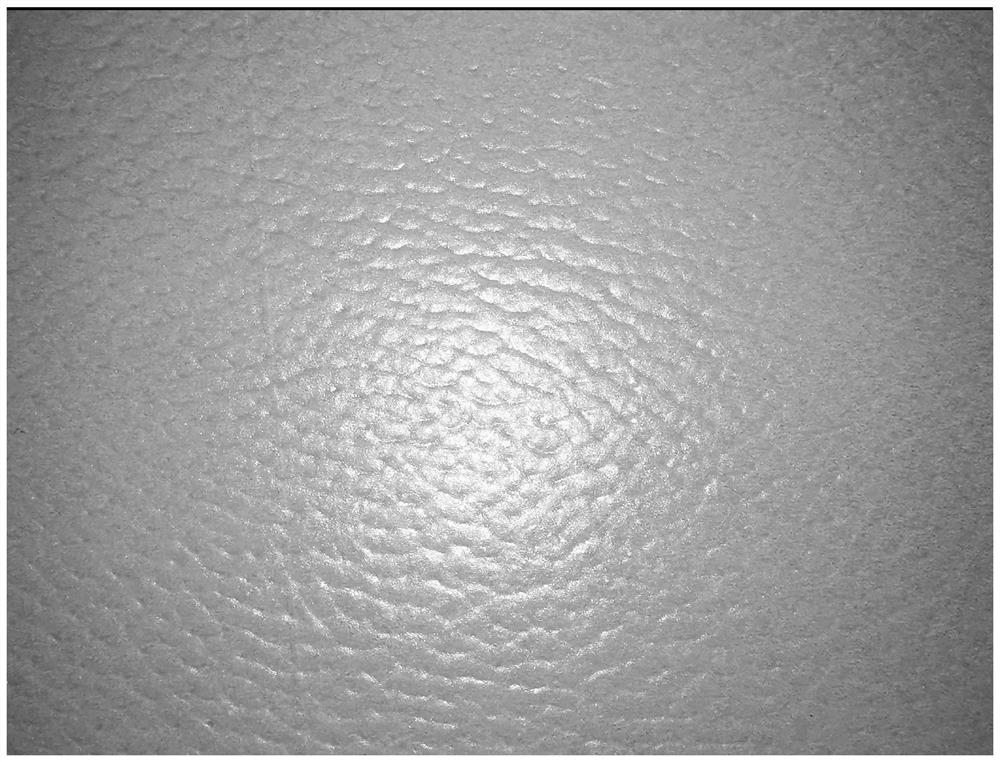

Embodiment 1

[0037] A slate, comprising the steps of:

[0038] S1. Print the concave-convex pattern of leather texture on the green body with matte oily ink;

[0039] S2. Apply zirconium white matt surface glaze, the application amount is 600 grams per square meter, and dry;

[0040] S3. Print leather color patterns with ceramic inkjet ink;

[0041]S4. apply imitation leather grain glaze, the application amount is 250 grams per square meter;

[0042] S5. Burning;

[0043] S6. Polishing and edging.

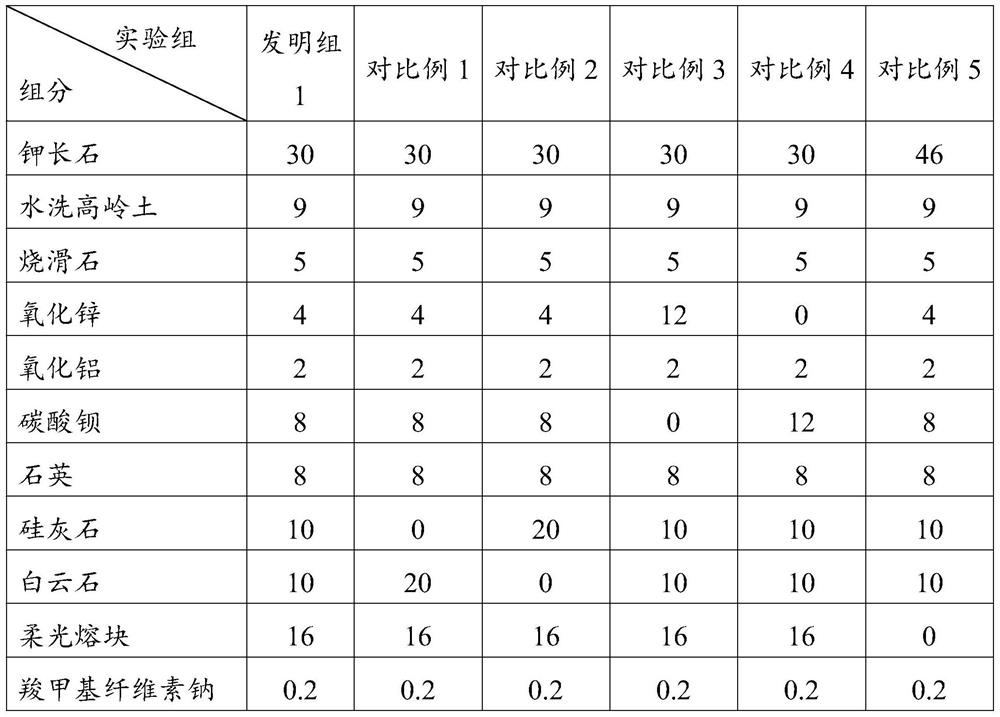

[0044] Wherein, the zirconium white matt glaze comprises the following components in parts by weight:

[0045] 15-20 parts by weight of potassium feldspar; 5-8 parts by weight of quartz; 20-25 parts by weight of nepheline; 6-8 parts by weight of zirconium silicate; 9-11 parts by weight of white alumina stone; 5-8 parts by weight of dolomite; 1-3 parts by weight of calcined talc; 2-5 parts by weight of albite; 15-20 parts by weight of washed kaolin.

[0046] The described leather-like glaz...

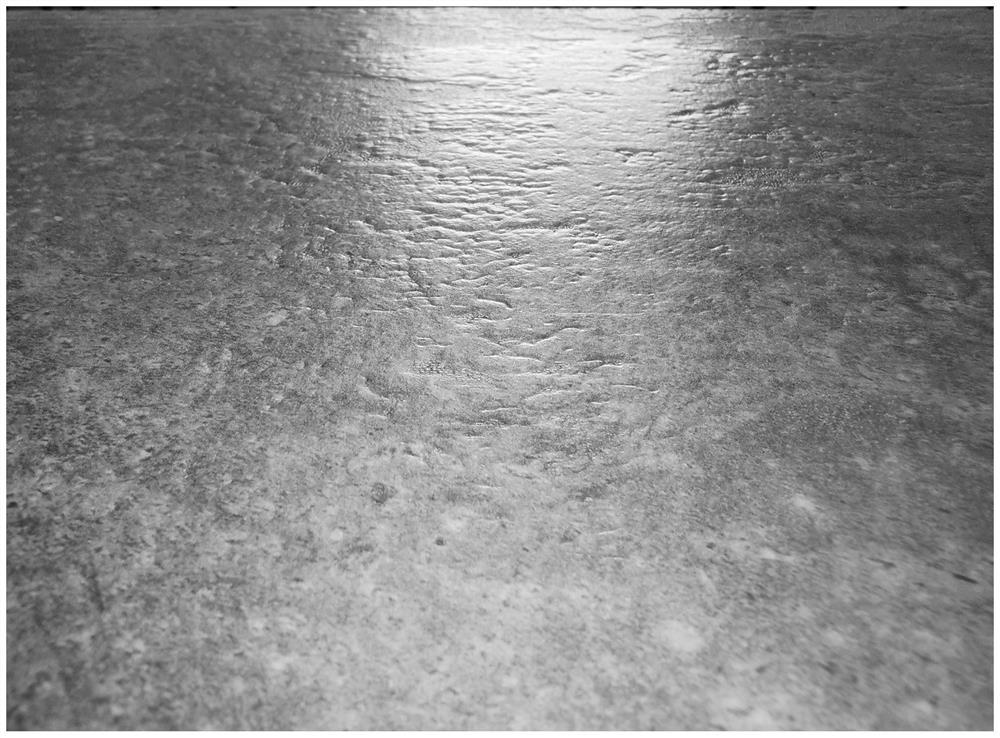

Embodiment 2

[0050] A slate, comprising the steps of:

[0051] S1. Print the concave-convex pattern of the volcanic rock texture on the green body with matte oily ink;

[0052] S2. Apply zirconium white matt surface glaze, the application amount is 600 grams per square meter, and dry;

[0053] S3. Print the volcanic rock color pattern with ceramic inkjet ink;

[0054] S4. Applying imitation volcanic rock glaze, the application amount is 250 grams per square meter;

[0055] S5. Burning;

[0056] S6. Polishing and edging.

[0057] Wherein, the zirconium white matt glaze comprises the following components in parts by weight:

[0058] 15-20 parts by weight of potassium feldspar; 5-8 parts by weight of quartz; 20-25 parts by weight of nepheline; 6-8 parts by weight of zirconium silicate; 9-11 parts by weight of white alumina stone; 5-8 parts by weight of dolomite; 1-3 parts by weight of calcined talc; 2-5 parts by weight of albite; 15-20 parts by weight of washed kaolin.

[0059] Describe...

Embodiment 3

[0063] A slate, comprising the steps of:

[0064] S1. Print concave-convex patterns on the green body with matte oily ink;

[0065] S2. Apply zirconium white matt surface glaze, the application amount is 600 grams per square meter, and dry;

[0066] S3. Print the color pattern with ceramic inkjet ink;

[0067] S4. Apply soft light effect glaze (commercially available product), the application amount is 250 grams per square meter;

[0068] S5. Burning;

[0069] S6. Polishing and edging.

[0070] Wherein, the zirconium white matt glaze comprises the following components in parts by weight:

[0071] 15-20 parts by weight of potassium feldspar; 5-8 parts by weight of quartz; 20-25 parts by weight of nepheline; 6-8 parts by weight of zirconium silicate; 9-11 parts by weight of white alumina stone; 5-8 parts by weight of dolomite; 1-3 parts by weight of calcined talc; 2-5 parts by weight of albite; 15-20 parts by weight of washed kaolin.

[0072] Due to the use of the soft lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com