Preparation method of polyvinyl chloride resin with large particle size and narrow distribution

A technology of polyvinyl chloride resin and narrow distribution, which is applied in the field of polymer materials to achieve the effect of high chlorine content, loose particle structure, and favorable chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

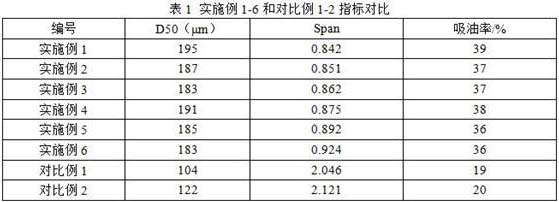

Examples

Embodiment 1

[0026] S1. Mix 100kg vinyl chloride monomer, 0.05kg polyvinyl alcohol with 72% degree of alcoholysis, 0.03kg hydroxypropyl cellulose with 10% hydroxypropyl content, 0.04kg di(2-ethyl)hexyl peroxydicarbonate Ester, 0.05kg sodium bicarbonate, 0.05kg dibutyltin dilaurate and 160kg deionized water were added into the polymerization kettle and mixed evenly. Stir at 20°C for 30 minutes;

[0027] S2, heat up, and carry out the polymerization reaction under the reaction condition of 50° C., and the polymerization time is 1 hour;

[0028] S3, add 100kg vinyl chloride monomer, 0.02kg polyvinyl alcohol with 72% alcoholysis degree, 0.01kg hydroxypropyl cellulose with 10% hydroxypropyl content, 0.02kg di(2-ethyl) peroxydicarbonate Hexyl ester, 160kg deionized water, polymerized under the reaction conditions of 60°C, the polymerization time was 2 hours;

[0029] S4, adding 0.1kg bisphenol A terminator to terminate the polymerization reaction;

[0030] S5. The above resin slurry is stripp...

Embodiment 2

[0033] S1. Mix 100kg vinyl chloride monomer, 0.05kg polyvinyl alcohol with 78% degree of alcoholysis, 0.03kg hydroxypropyl cellulose with 10% hydroxypropyl content, 0.05kg di(2-ethyl)hexyl peroxydicarbonate Ester, 0.05kg sodium bicarbonate, 0.05kg dibutyltin dilaurate and 160kg deionized water were added into the polymerization kettle and mixed evenly. Stir at 20°C for 30 minutes;

[0034] S2, heat up, and carry out the polymerization reaction under the reaction condition of 50° C., and the polymerization time is 1 hour;

[0035] S3, add 100kg vinyl chloride monomer, 0.02kg polyvinyl alcohol with 78% alcoholysis degree, 0.01kg hydroxypropyl cellulose with 10% hydroxypropyl content, 0.02kg di(2-ethyl) peroxydicarbonate Hexyl ester, 160kg deionized water, polymerized under the reaction conditions of 60°C, the polymerization time was 2 hours;

[0036] S4, adding 0.1kg bisphenol A terminator to terminate the polymerization reaction;

[0037] S5. The above resin slurry is stripp...

Embodiment 3

[0040] S1. Mix 100kg vinyl chloride monomer, 0.05kg polyvinyl alcohol with 78% degree of alcoholysis, 0.03kg hydroxypropyl cellulose with 10% hydroxypropyl content, 0.02kg di(2-ethyl)hexyl peroxydicarbonate Ester, 0.05kg sodium bicarbonate, 0.05kg dibutyltin dilaurate and 160kg deionized water were added into the polymerization kettle and mixed evenly. Stir at 20°C for 30 minutes;

[0041] S2, heat up, and carry out the polymerization reaction under the reaction condition of 50° C., and the polymerization time is 2 hours;

[0042] S3, add 100kg vinyl chloride monomer, 0.02kg polyvinyl alcohol with 78% alcoholysis degree, 0.01kg hydroxypropyl cellulose with 10% hydroxypropyl content, 0.02kg di(2-ethyl) peroxydicarbonate Hexyl ester and 160kg deionized water were polymerized under the reaction conditions of 60°C, and the polymerization time was 2 hours;

[0043] S4, adding 0.1kg bisphenol A terminator to terminate the polymerization reaction;

[0044] S5. The above resin slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com