Filament high-temperature steam processor

A high-temperature steam and processing machine technology, which is applied in the heat treatment of artificial filaments, mechanical equipment, engine components, etc., can solve the problems of reducing the utilization rate of steam, achieve the effects of reducing the probability of overflow, increasing the temperature, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

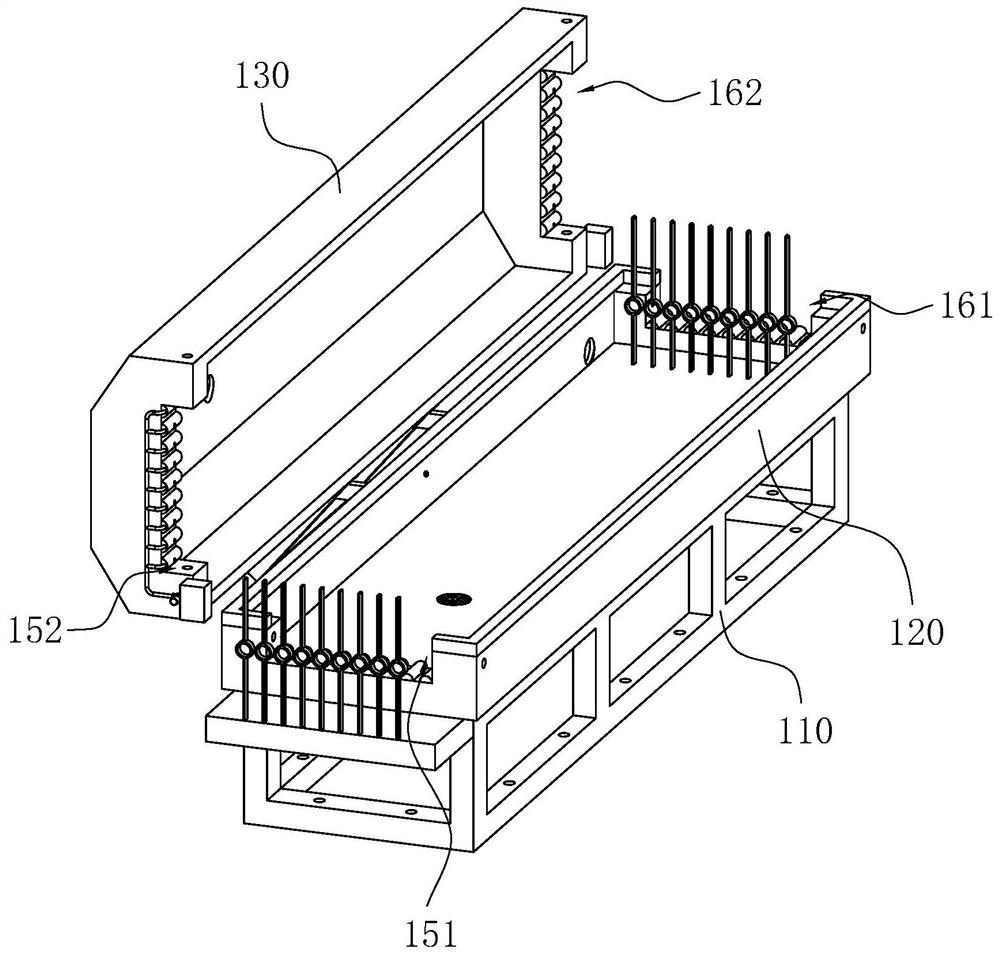

[0041] The following is attached Figure 1-4 The present invention is described in further detail.

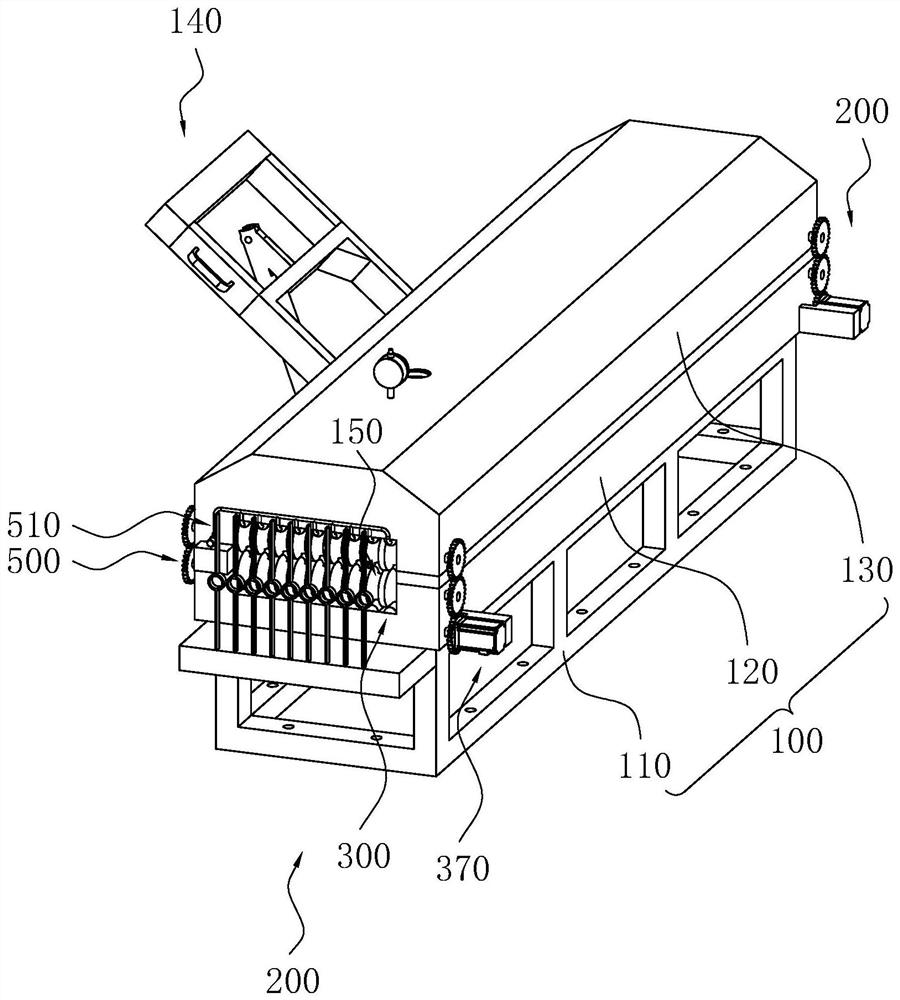

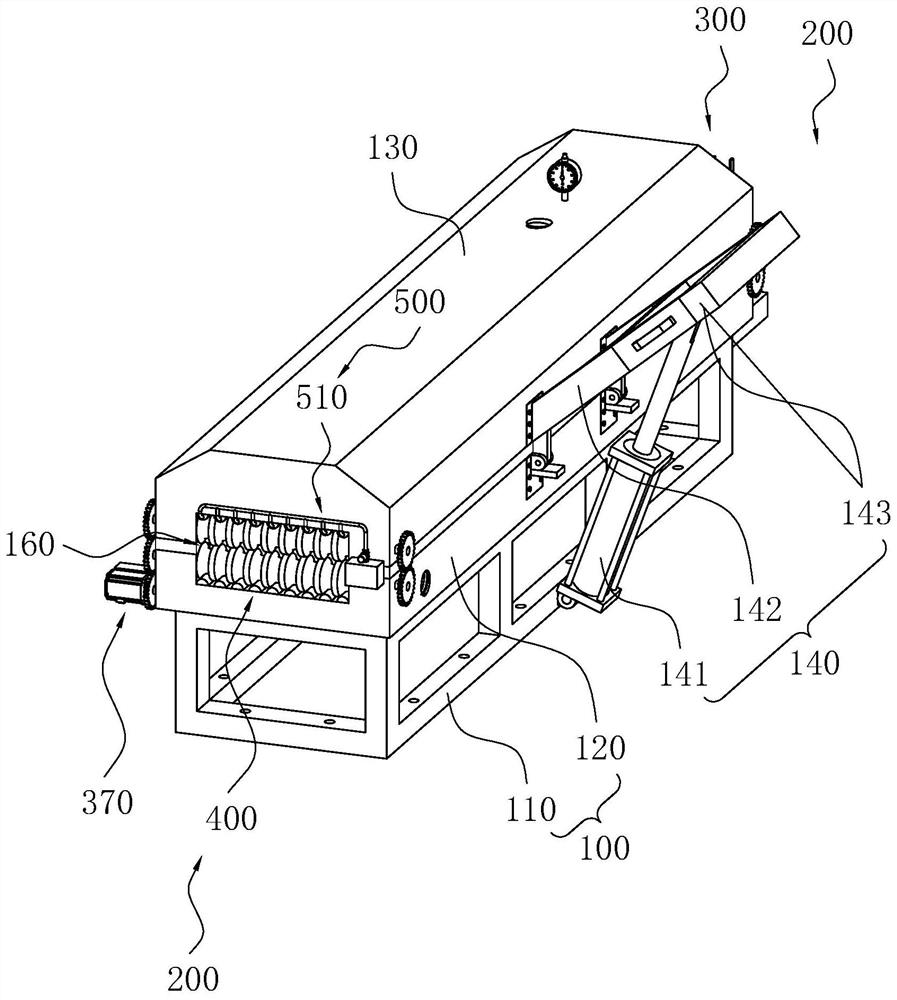

[0042] The embodiment of the present application discloses a filament high-temperature steam processing machine. refer to figure 1 and figure 2 , the filament high-temperature steam processing machine includes a casing 100, one end of the length direction of the casing 100 is provided with a feeding port 150, and the other end is provided with a discharging port 160; the casing 100 is provided with a sealing device 200 for sealing the casing 100 And a lubricating device 500 for lubricating the sealing device 200 , the sealing device 200 includes a first sealing mechanism 300 for sealing the feeding opening 150 and a second sealing mechanism 400 for sealing the feeding opening 160 . When using steam to process filaments, the filaments enter the box body 100 through the first sealing mechanism 300 from the feeding port 150, and then the filaments are processed by the steam in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com