Overflow dyeing machine uniform in dyeing

An overflow dyeing machine and uniform technology, applied in the field of dyeing machines, can solve the problems of poor quality of finished fabrics, complicated structure of dyeing machines, uneven dyeing of fabrics, etc., and achieve the effects of saving costs, improving dyeing uniformity and smooth dyeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

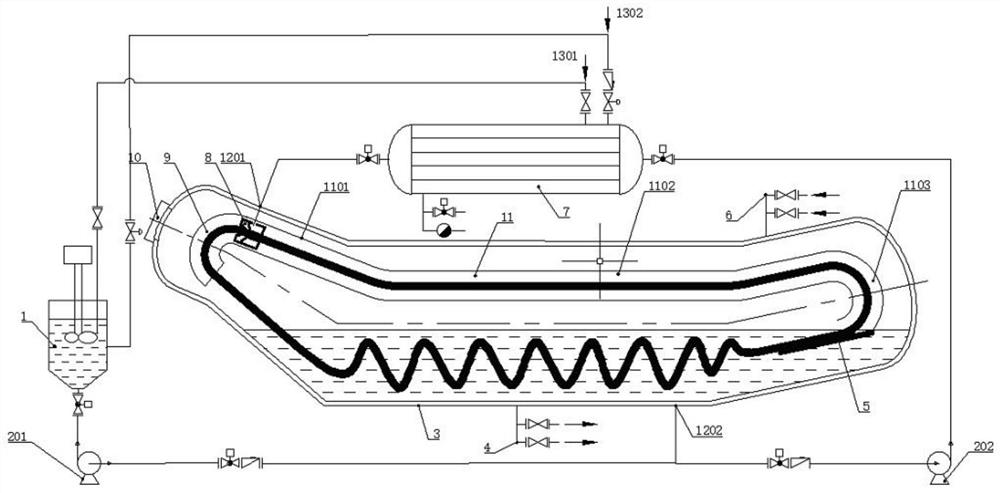

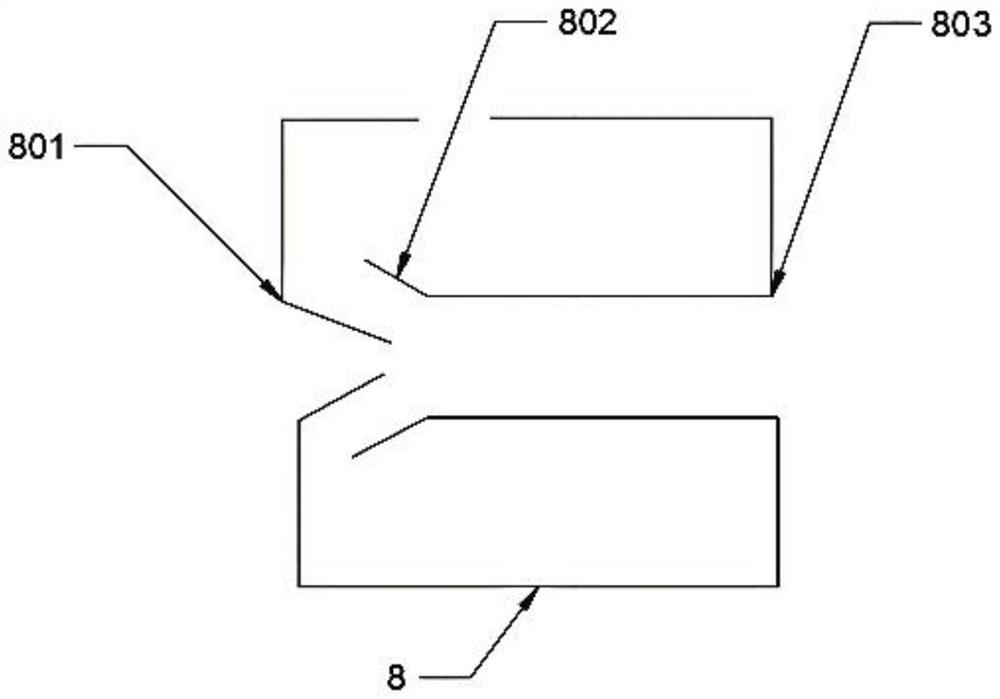

[0024] Such as Figure 1-2 As shown, the present invention discloses an overflow dyeing machine with uniform dyeing, which is characterized in that: it includes a cylinder body 3; a cloth guide pipe 11 is arranged inside the cylinder body 3; A guideable elbow 9 is installed on the top; a nozzle 8 is provided at the connection position between the elbow 9 and the cloth guide pipe 11; the nozzle 8 and the cloth guide pipe 11 are connected by a flange; the bottom of the cylinder body is provided with a cloth guide groove 5. The position of the cloth guide groove 5 is determined by the nozzle 8, the cloth guide groove 5 determines the forward kinetic energy of the cloth, and is arranged radially, so that the cloth guide groove 5 regulates the slack of the cloth in the dye solution, so that the cloth in the dye solution space is reasonable distribution, so that the cloth is not easy to wrinkle in the dye solution. Especially for light fabrics or fabrics that wrinkle easily. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com