A laser tracker plane coordinate high precision lofting device and method

A technology of laser tracker and plane coordinates, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as tilt errors, errors, and debris, so as to eliminate coordinate lofting errors, improve accuracy and efficiency, and reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

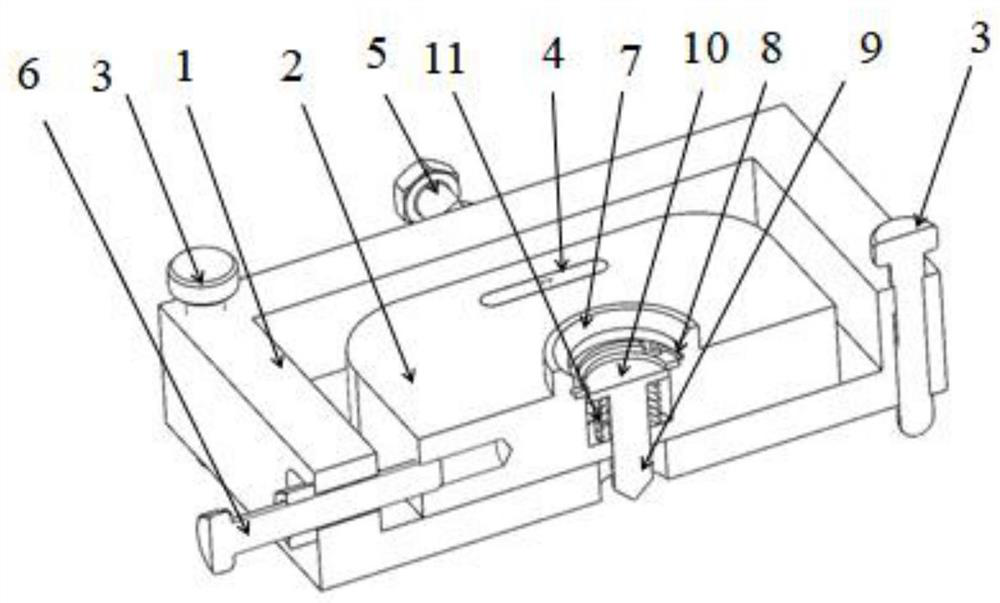

[0048] According to an embodiment of the present invention, the base body 2 is a regular tetrahedron, and two horizontal bubble meters 4 are respectively disposed on adjacent two sides of the base body 2 .

[0049] However, the distance between the horizontal bubble meter 4 and the center of the base body 2 should not be too large, otherwise the overall structure will be too large and complex, the machining accuracy will not be guaranteed, and the cost will be high.

[0050] According to an embodiment of the present invention, the distance between the center of the horizontal bubble meter 4 and the center of the base body 2 is 50±5 mm.

[0051] According to an embodiment of the present invention, the horizontal adjustment part is a horizontal adjustment screw rod 3, the horizontal adjustment screw rod 3 is a group, and the group of horizontal adjustment screw rods 3 is distributed on the periphery of the base 1 to adjust the vertical screw rod Height of different positions of ...

Embodiment 1

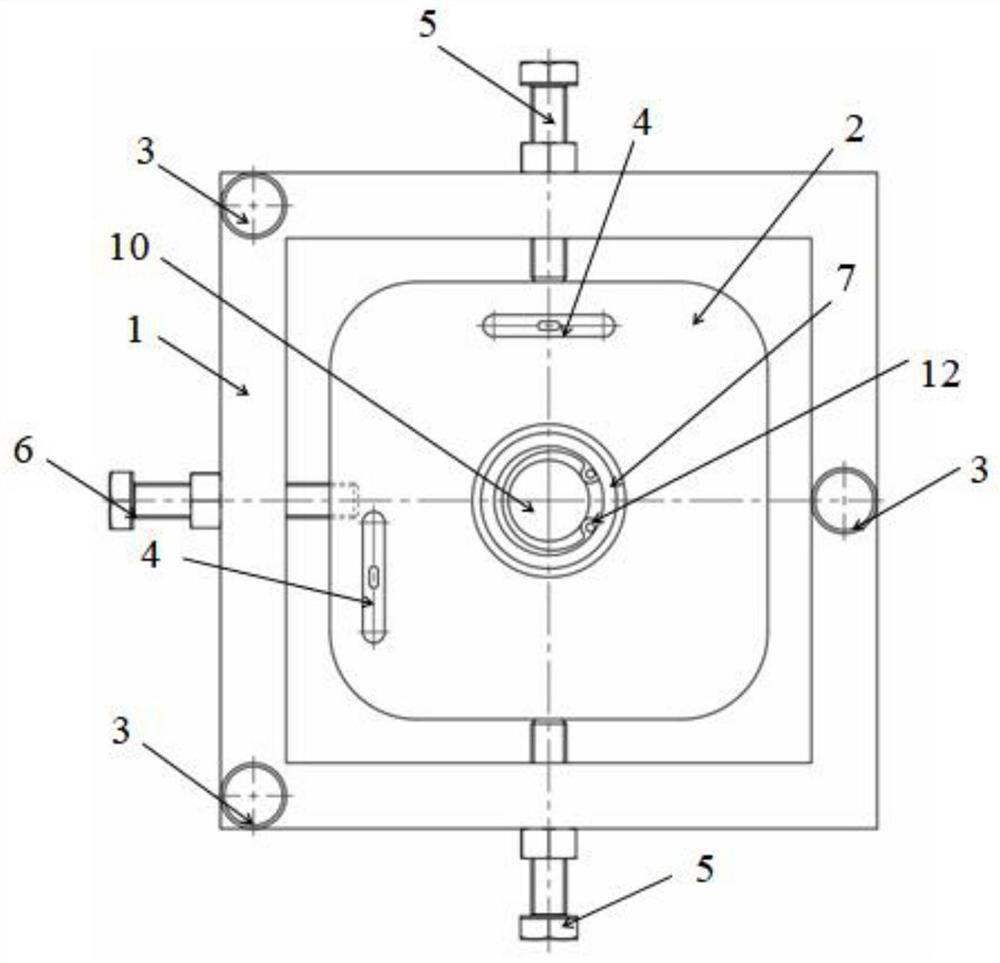

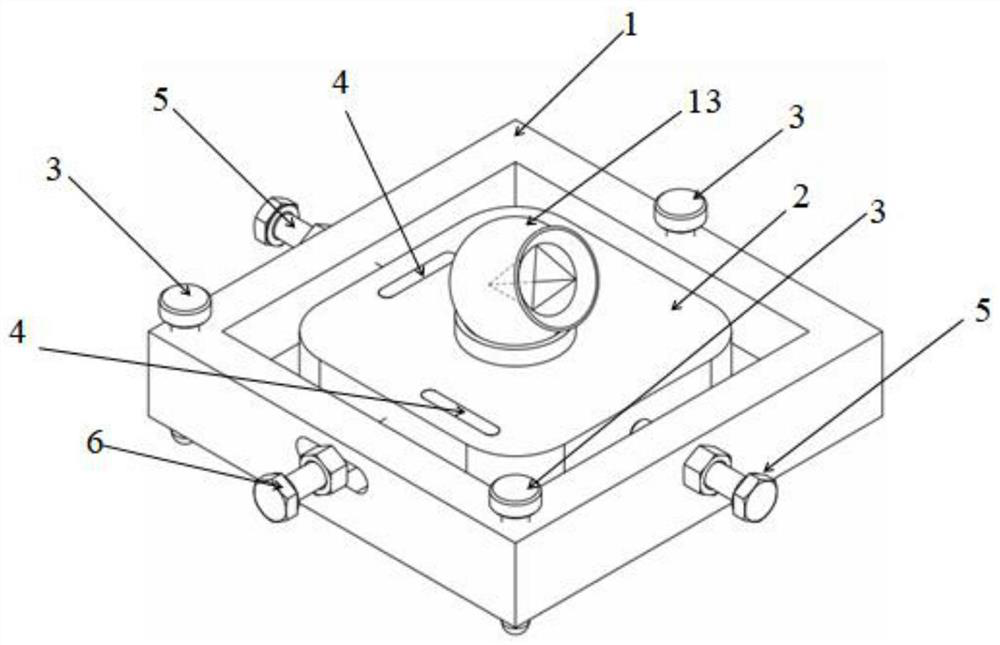

[0086] The embodiment of the present invention discloses a device for high-precision lofting of plane coordinates of a laser tracker, such as Figure 1 to Figure 4 shown.

[0087] The base 1 and the base body 2 of the laser tracker plane coordinate high-precision stakeout device in this embodiment are made of 304 stainless steel, and the shapes are both equilateral quadrilateral structures, wherein each corner of the equilateral quadrilateral of the base body 2 is a chamfered structure.

[0088]At the center of the two adjacent corners of the base 1 of the high-precision lofting device for plane coordinates of the laser tracker and the center of the opposite side of the side where the two corners are located, there are a total of three horizontal adjustment screw rods 3 that can be manually adjusted. The horizontal adjustment screw The rod 3 is made of 304 stainless steel, and is connected to the base 1 through a wire hole, and the upper end is a circular anti-skid knob struct...

Embodiment 2

[0099] This embodiment provides a method for using a laser tracker plane coordinate high-precision stakeout device, using the laser tracker plane coordinate high-precision stakeout device provided in Embodiment 1, the key points of the synchrotron magnet and support system of the heavy ion therapy device are Taking the setting out of the base surface of the synchrotron installation as an example to describe the use method of the high-precision setting out device for the plane coordinates of the laser tracker, the method may include the following steps:

[0100] Step S1 : the laser tracker 14 is installed on the site of the synchrotron of the heavy ion therapy device. The laser tracker 14 is free to set up stations, and the erection position needs to meet enough three-dimensional collimation control points (generally more than 8 control points of different planes) that can measure within a range of about 10m at the same station, and it is also necessary to ensure that the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com