Continuous gyro measuring device

A technology of measuring device and gyroscope, applied in the direction of measuring device, Sagnac effect gyroscope, gyroscope/steering sensing device, etc., can solve the problems of limiting measuring instrument, increasing measuring time, increasing customer cost, etc., to achieve accurate and stable Measured data, high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

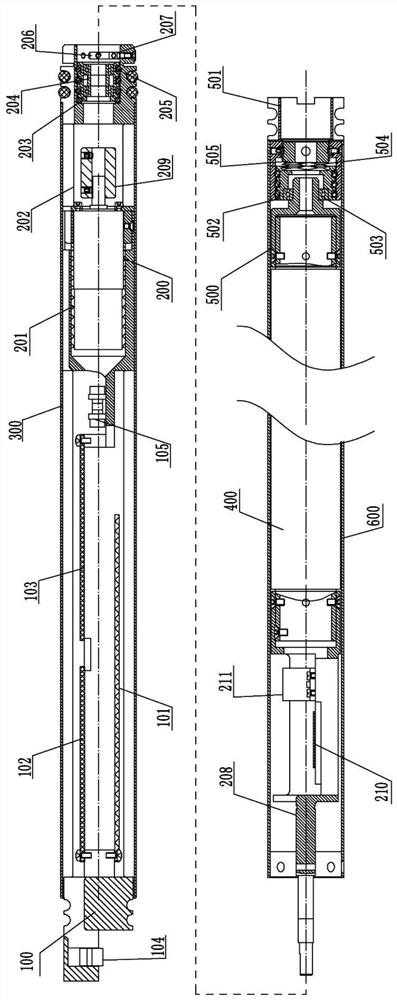

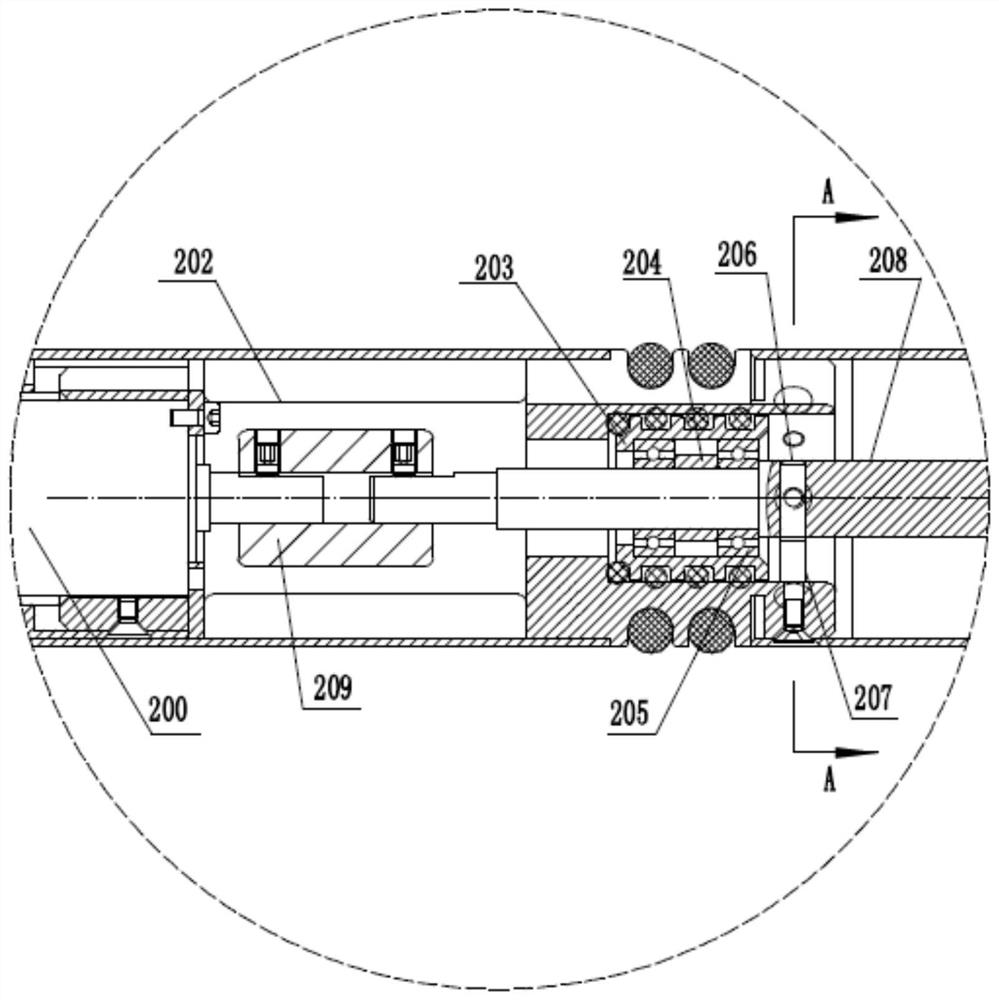

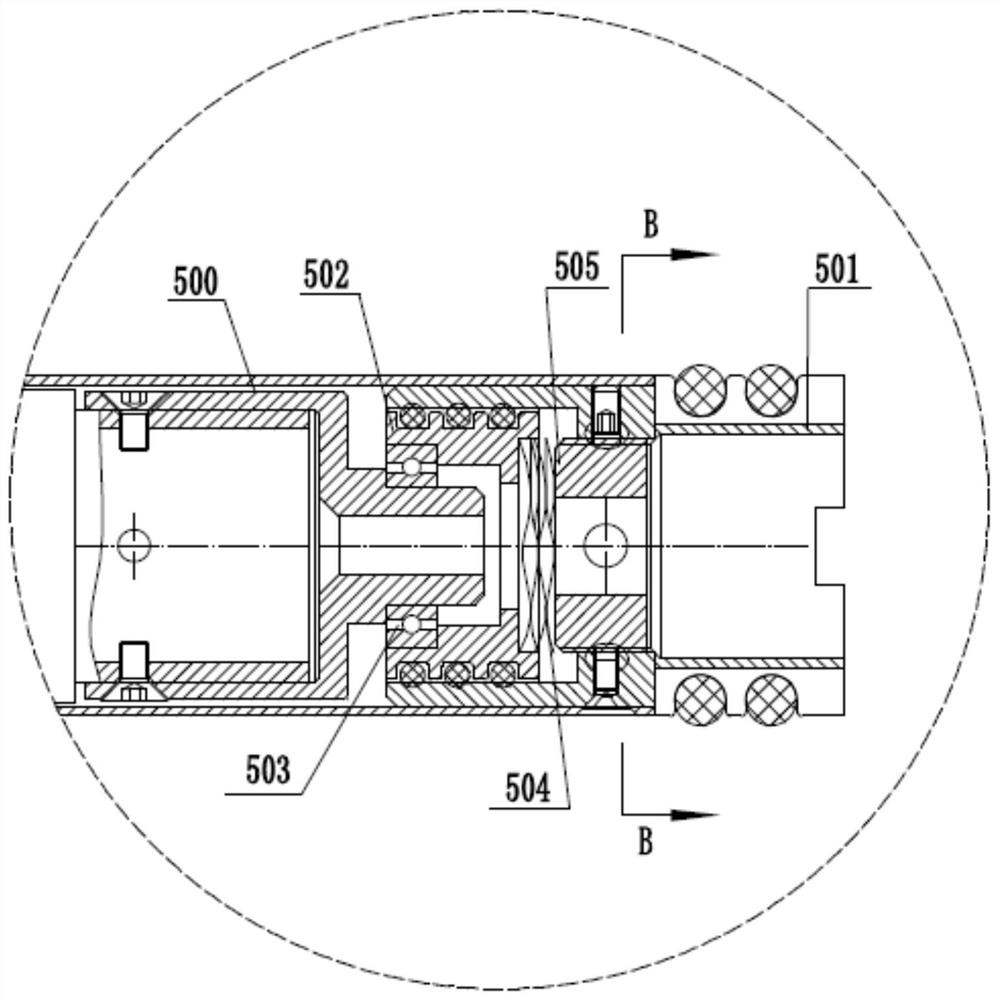

[0022] Such as figure 1 As shown, a continuous gyro measuring device according to an embodiment of the present invention includes a circuit module, a transmission module, a gyro core 400, a fixing module and a protection module, and the circuit module includes a circuit board bracket 100, a fiber optic gyro control board 101, a carrier communication Circuit board 102, fiber optic gyro power supply board 103, fixed macro-distance socket 104 and micro-rectangular connector socket 105, the transmission module includes two-phase stepping motor 200, motor protection cover 201, motor bracket 202, first bearing sleeve 203, Shaft sleeve 204, first deep groove ball bearing 205, counter-rotating shaft 206, limit shaft 207, transmission shaft 208, elastic coupling 209, adapter plate 210, and accelerometer 211, and the fixing module includes a centering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com