High-voltage high-power servo controller busbar

A servo controller, busbar technology, applied in the direction of fixed/insulated contact members, electrical components, rods/rods/wires/strip conductors, etc., can solve the time cost, price cost, labor cost and reliability issues that cannot be ignored, Problems such as wiring errors and complicated wiring can improve accessibility and system reliability, facilitate mass production of products, and optimize internal space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

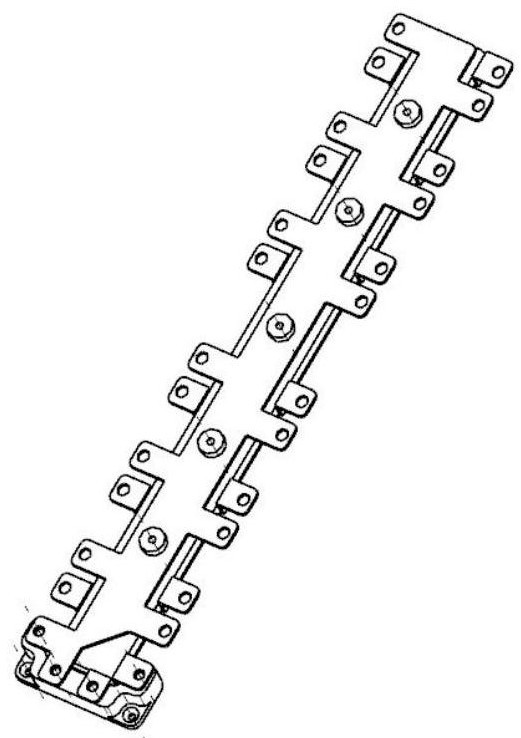

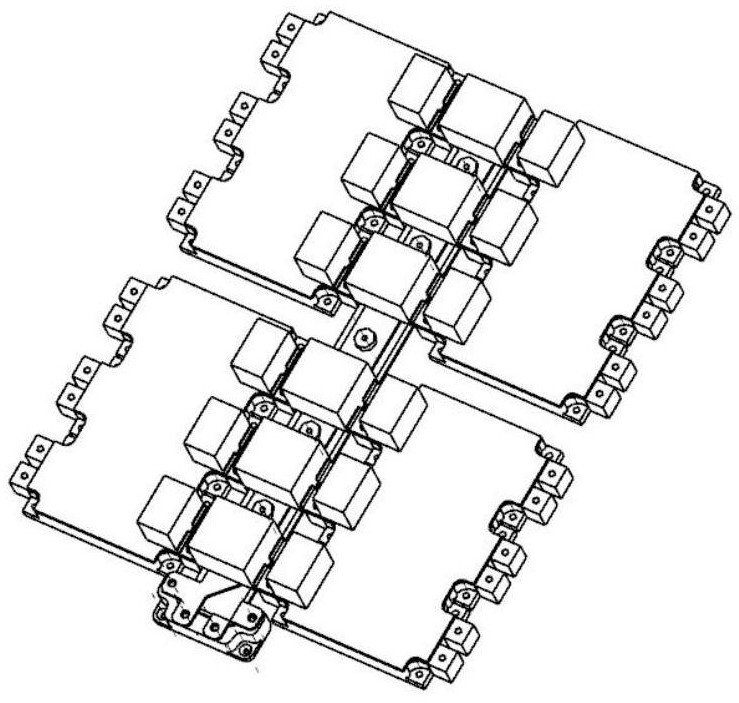

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

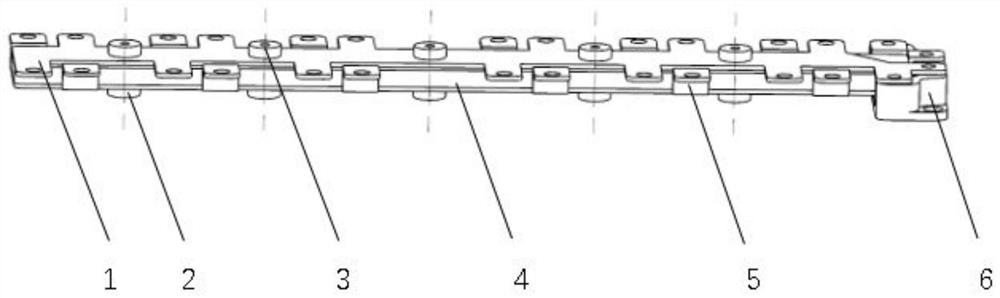

[0023] The present invention provides a high-voltage and high-power servo controller with high reliability confluence integrated row, and the technical scheme adopted is as follows:

[0024] It includes a positive bus bar, a negative bus bar, an upper insulating column, a lower insulating column, an insulator and an insulating support.

[0025] The positive bus bar is used to conduct the positive connection of the components, and the negative bus bar is used to conduct the negative connection of the components.

[0026] Optionally, the positive bus bar and the negative bus bar are made of pure copper.

[0027] The insulator is used to separate the positive bus bar from the negative bus bar, so as to effectively prevent the short circuit caused by connecting the bus bars of different poles.

[0028] Optionally, the insulator adopts polytetrafluoroethylene ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com