Hybrid excitation permanent magnet reluctance linear motor type control rod driving mechanism

A technology of linear motor and mixed excitation, which is applied in the direction of electric components, nuclear reaction control, structural connection, etc., can solve the problems of difficult manufacturing, mechanical wear, and poor control accuracy of reactor power, so as to improve power control accuracy and broaden speed regulation Range, the effect of not easy demagnetization failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

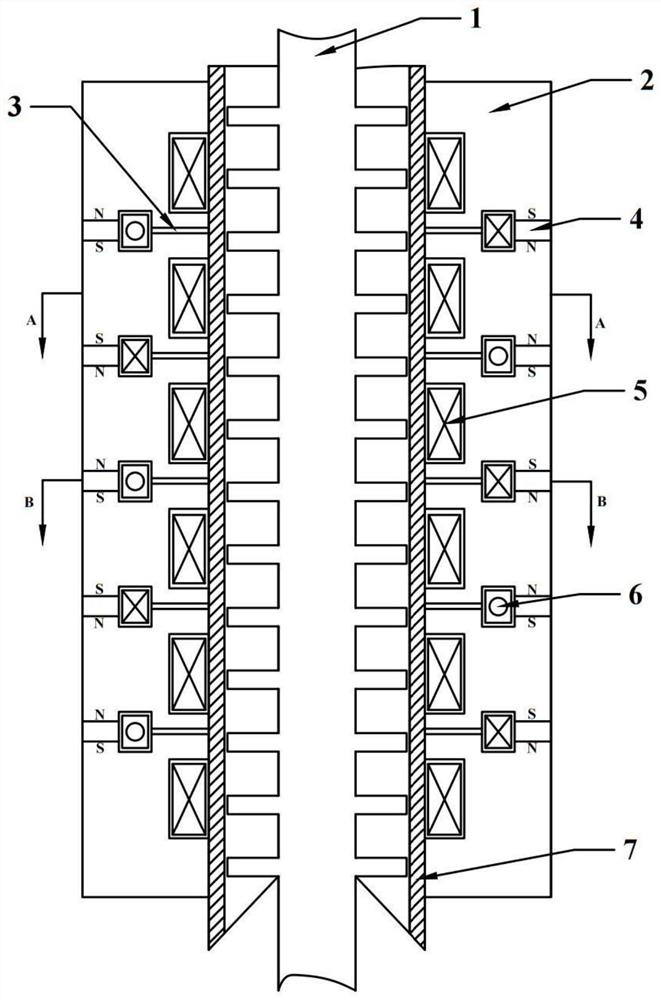

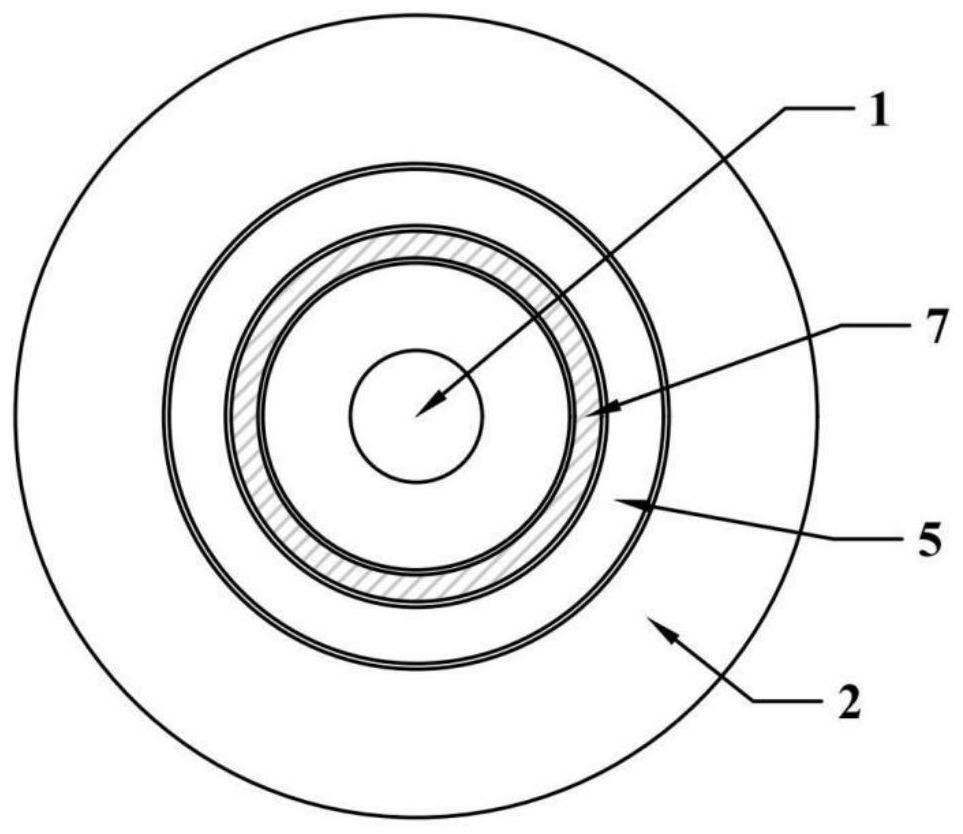

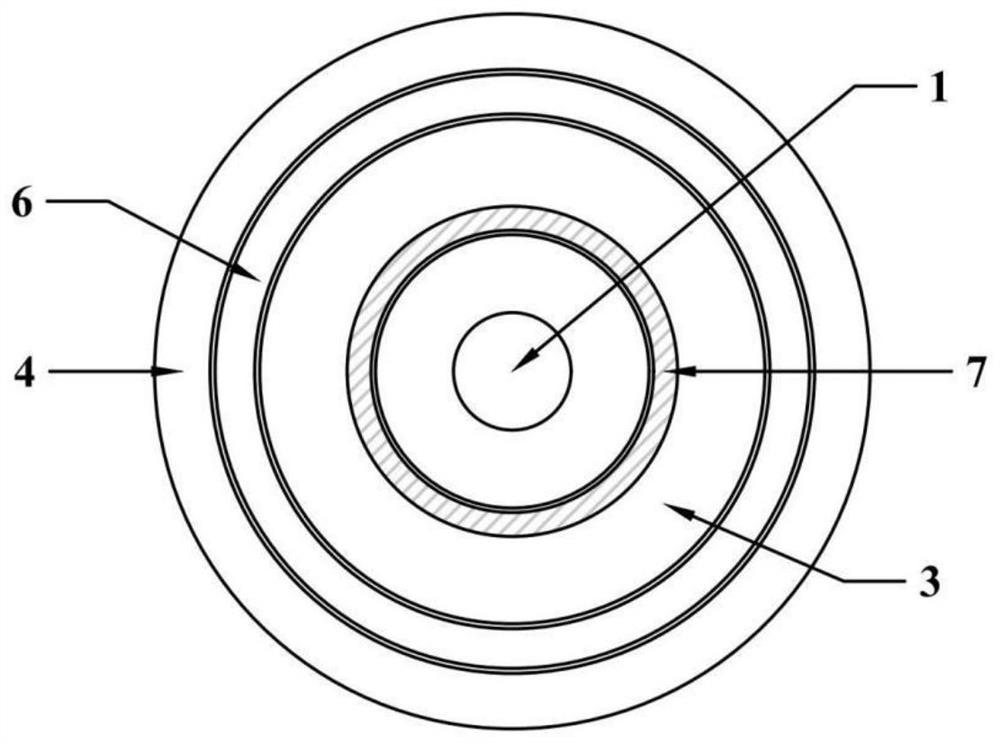

[0035] A hybrid excitation permanent magnet reluctance linear motor type control rod drive mechanism, comprising a cylindrical permanent magnet reluctance linear motor, a holding coil 5 and a pressure-resistant shell 7; the cylindrical permanent magnet reluctance linear motor consists of Drive rod (mover) 1, stator 2, magnetic isolation ring 3, permanent magnet 4 and stator winding 6; drive rod (mover) 1 is located at the innermost layer of the entire mechanism, and stator 2 is located at the outermost layer of the entire mechanism. There is a pressure-resistant shell 7 in the air gap between the driving rod (mover) 1 and the stator 2, and the three are coaxially arranged; the stator 2 includes several stator cores arranged at intervals along the axial direction of the driving rod 1, and the stator cores There is an annular groove on the inner surface, and an annular auxiliary groove is formed between adjacent stator cores. The magnetic isolation ring 3 is embedded in the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com