Recyclable film for thermoforming

A technology of thermoforming and base film, which can be used in applications, household packaging, household appliances, etc., and can solve problems such as warping, curling, and poorly formed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0142] Examples of thermoformable base films:

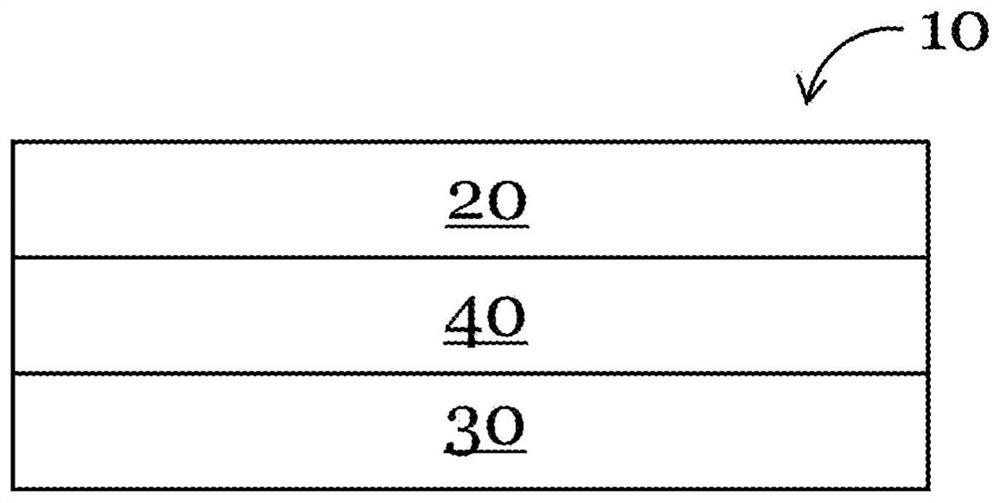

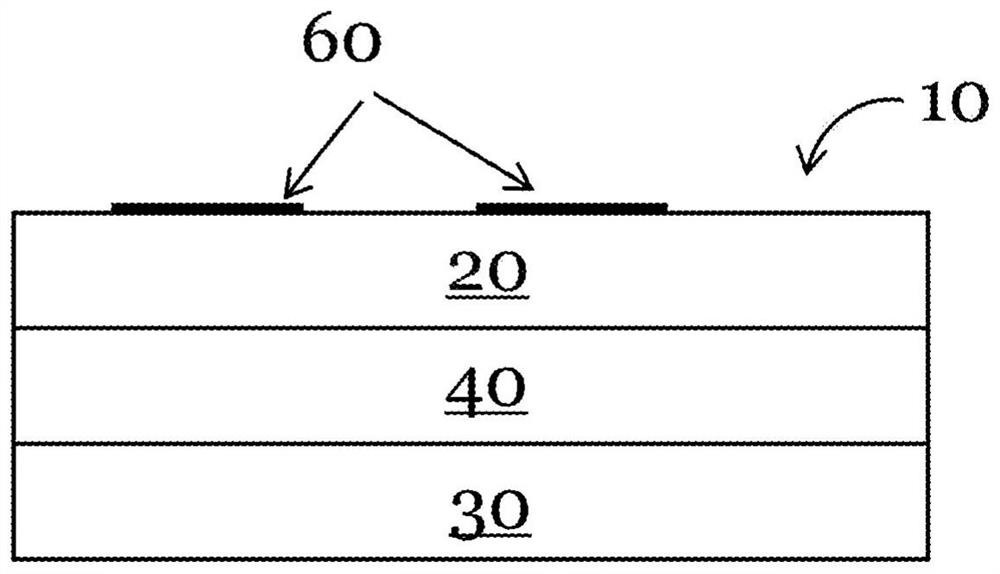

[0143] A. A thermoformable base film comprising:

[0144] Contains at least one polyethylene and has a 3 and 0.97g / cm 3 The total density between the first layer,

[0145] a second layer comprising high-density polyethylene and hydrocarbon resin, and

[0146] Contains at least one polyethylene and has a 3 and 0.97g / cm 3 The third layer of total density between,

[0147] Wherein the second layer is located between the first layer and the third layer, and wherein after thermoforming, the thermoformable base film retains the shape formed during thermoforming.

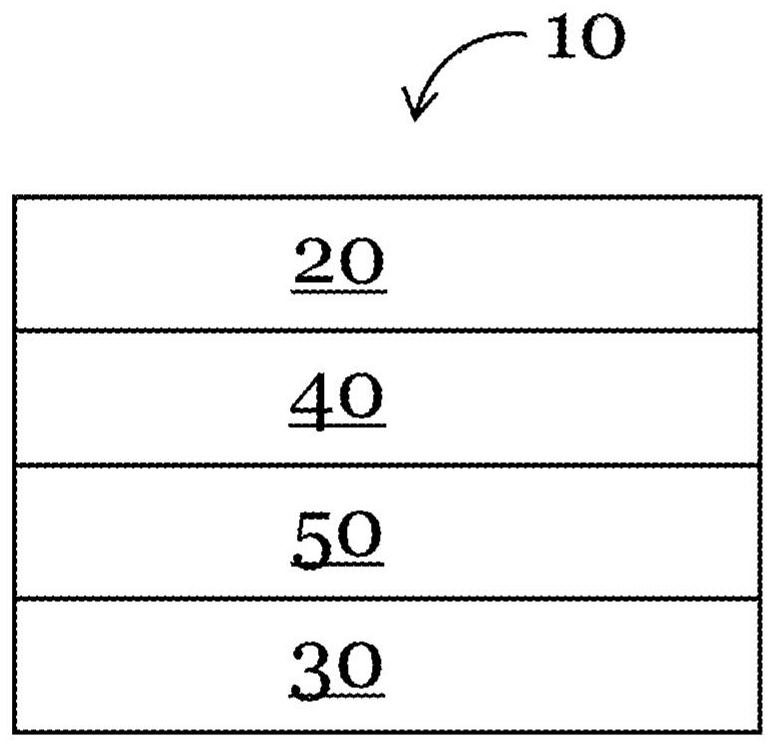

[0148] B. The thermoformable base film of any other embodiment, further comprising a fourth layer comprising high density polyethylene and inorganic particles, wherein the inorganic particles are present in the fourth layer at a level of at least 5% by weight , and wherein the fourth layer is between the first layer and the third layer.

[0149] C. The thermoformable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com