Resin sheet with support

A resin sheet and support technology, applied in the direction of synthetic resin layered products, electrical solid devices, electrical components, etc., can solve the problems of no light emission, decreased brightness, peeling, etc., and achieve the effect of high moisture barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

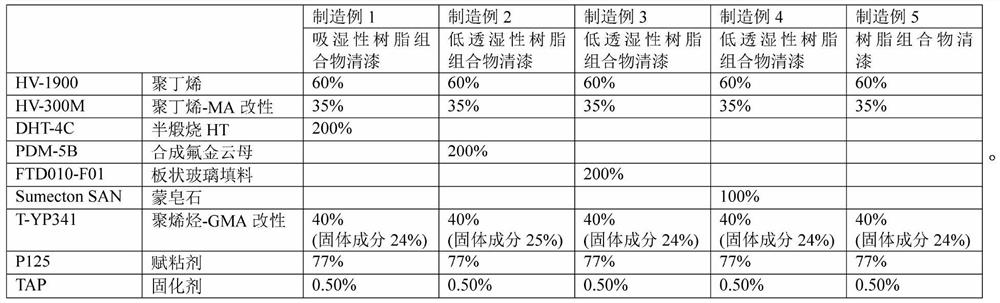

manufacture example 1

[0150] Varnishes having the compounding ratios shown in Table 1 below were prepared according to the following procedure. Using a three-roll mill, maleic anhydride-modified liquid polybutene (HV-300M, manufactured by Nippon Mitsubishi Corporation), polybutene (HV-1900, manufactured by Nippon Mitsubishi Corporation) and semi-calcined hydrotalcite (hygroscopic filler ; DHT-4C, manufactured by Kyowa Chemical Co., Ltd.) was dispersed in a product obtained by dissolving a saturated hydrocarbon resin (tackifier; ARKON P125) containing a cyclohexane ring in SWASOL so that the solid content became 60%, and a mixture was obtained. . In the obtained mixture, a glycidyl methacrylate modified polypropylene-polybutene copolymer (T-YP341 (manufactured by Starlight PMC Co., Ltd.), SWASOL solution, solid content 20%), an anionic polymerization type curing agent (TAP, Kayaku Akzo Co., Ltd.) and toluene, and the resulting mixture was uniformly dispersed with a high-speed rotary mixer to obtain...

manufacture example 2

[0152] Varnishes having the compounding ratios shown in Table 1 below were prepared according to the following procedure. Using a three-roll mill, maleic anhydride-modified liquid polybutene (HV-300M, manufactured by Nippon Mitsubishi Corporation), polybutene (HV-1900, manufactured by Nippon Mitsubishi Corporation) and synthetic fluorophlogopite (plate-shaped filler ; PDM-5B, manufactured by TOPY Industry Co., Ltd.) was dispersed in a product obtained by dissolving a cyclohexane ring-containing saturated hydrocarbon resin (tackifier; ARKONP125) in SWASOL so that the solid content became 60%, to obtain a mixture. In the obtained mixture, a glycidyl methacrylate modified polypropylene-polybutene copolymer (T-YP341 (manufactured by Starlight PMC Co., Ltd.), SWASOL solution, solid content 20%), an anionic polymerization type curing agent (TAP, Kayaku Akzo Co., Ltd.) and toluene, and the obtained mixture was uniformly dispersed with a high-speed rotary mixer to obtain a varnish of ...

manufacture example 3

[0154] Varnishes having the compounding ratios shown in Table 1 below were prepared according to the following procedure. Using a three-roller mill, maleic anhydride-modified liquid polybutene (HV-300M, manufactured by Starlight PMC Company), polybutene (HV-1900, manufactured by Starlight PMC Company) and plate glass filler (FTD010-F01, Japan Panglass Co., Ltd.) was dispersed in a product obtained by dissolving a cyclohexane ring-containing saturated hydrocarbon resin (tackifier; ARKONP125) in SWASOL so that the solid content became 60%, to obtain a mixture. In the obtained mixture, a glycidyl methacrylate modified polypropylene-polybutene copolymer (T-YP341 (manufactured by Starlight PMC Co., Ltd.), SWASOL solution, solid content 20%), an anionic polymerization type curing agent (TAP, Kayaku Akzo Co., Ltd.) and toluene, and the obtained mixture was uniformly dispersed with a high-speed rotary mixer to obtain a varnish of a low moisture permeability resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com