Resin composition and resin sheet

A technology of resin composition and resin sheet, which is applied in the direction of synthetic resin layered products, electrical components, circuits, etc., can solve the problems of non-luminescence, brightness reduction, and deterioration of luminescent materials, and achieve the effect of high moisture barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

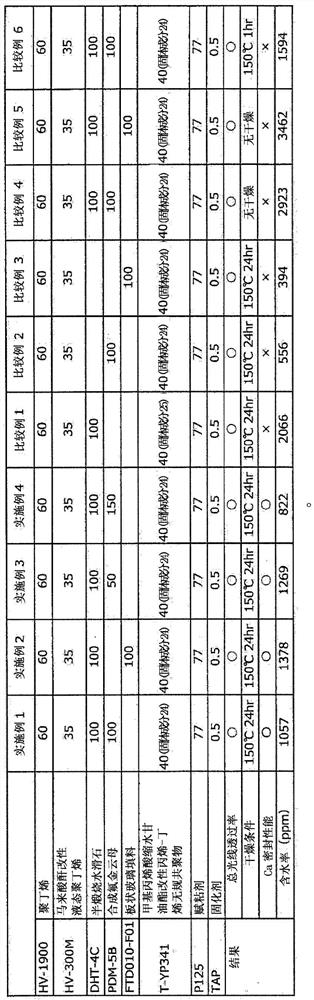

[0133] Hereinafter, the present invention will be described in further detail by citing the examples, but the present invention is not limited by the following examples, and of course can also be implemented by appropriately adding changes within the scope of the above / following gist, and they are all referred to as included in the technical scope of the present invention. In addition, unless otherwise specified, "part" and "%" in the quantity of a component and a copolymerization unit mean "mass part" and "mass %", respectively.

[0134] Materials used in Examples and Comparative Examples are as follows.

[0135] (A) Ingredients

[0136] "HV-1900" (manufactured by JX Energy Co., Ltd.): polybutene, number average molecular weight 2,900

[0137] "HV-300M" (manufactured by Toho Chemical Industry Co., Ltd.): Maleic anhydride-modified liquid polybutene with an anhydride group concentration of 0.77 mmol / g and a number average molecular weight of 2,100

[0138] "T-YP341" (manufactu...

Embodiment 2

[0150] Instead of synthetic fluorphlogopite (plate-shaped filler; PDM-5B, manufactured by TOPY Industry Co., Ltd.), a plate-shaped glass filler (FTD010-F01, manufactured by Nippon Plate Glass Co., Ltd.) was used, except that, using the same method as in Example 1, A varnish and a resin sheet of the resin composition are produced.

Embodiment 3

[0152] A varnish of the resin composition was prepared in the same manner as in Example 1, except that the amount of synthetic fluorphlogopite (plate-like filler; PDM-5B, produced by TOPY Industry Co., Ltd.) was changed from 100 parts to 50 parts. and resin sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com