Forming method and equipment for absorption core

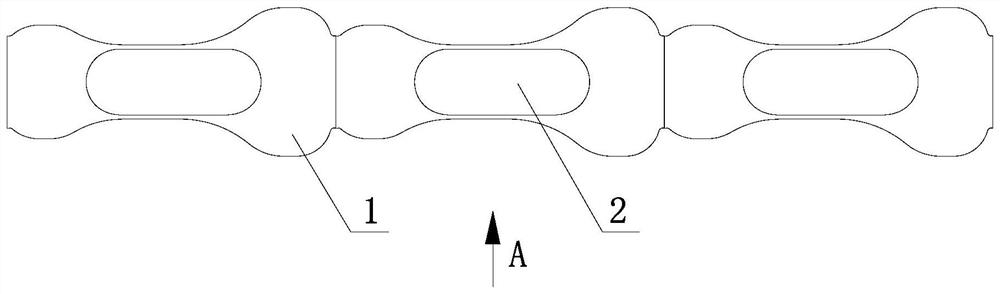

A technology of absorbent core and molding method, which is applied in the fields of absorbent pads, medical science, clothing, etc. It can solve the problems that fibers and polymer materials cannot be uniformly gathered and molded, the mold cavity 3 is discontinuous, and the molding effect is affected. Low maintenance difficulty, wide application range, and quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

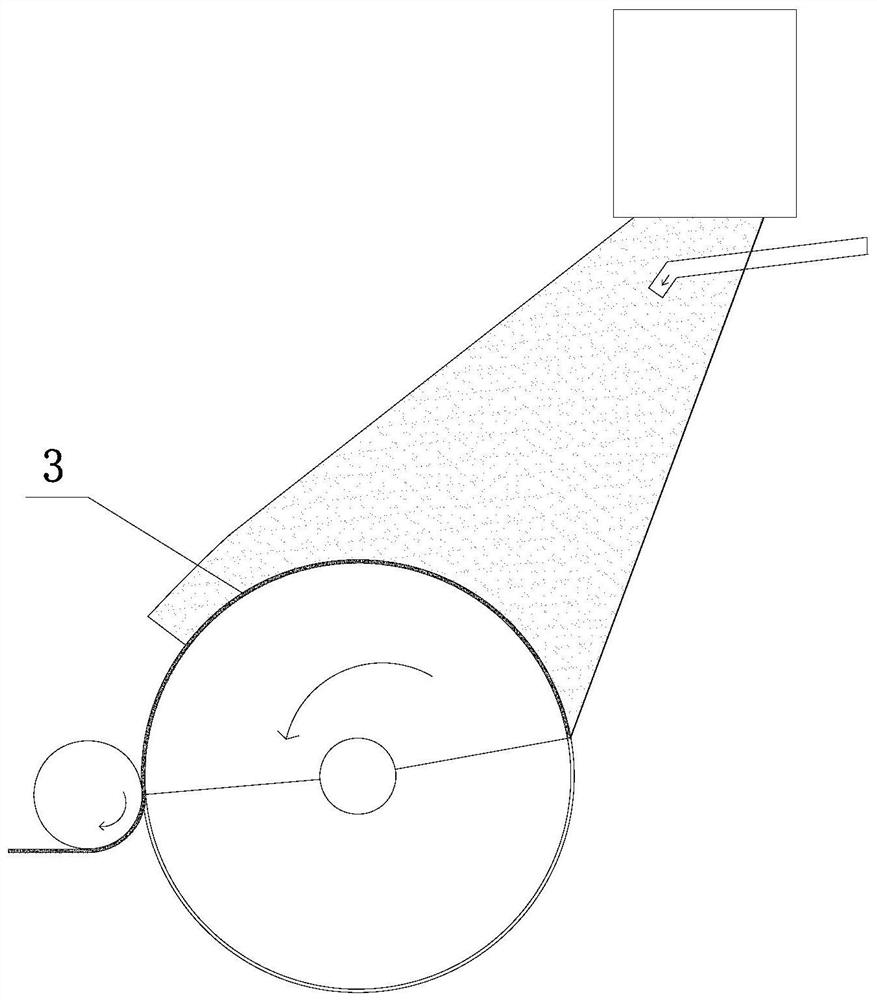

Embodiment 1

[0033] This embodiment is a molding equipment for an absorbent core, such as Image 6 or Figure 7 As shown, it includes a forming drum 4 and a plurality of forming components 5, each forming component is distributed along the circumferential direction of the forming drum and is installed on the forming drum, and each forming component rotates independently with respect to the mandrel 6 of the forming drum; the outer circumference of the forming drum The surface is provided with a forming area F and a demoulding area G, the rotational speed of each forming component in the forming area is lower than that in the demolding area, and the forming components located in the forming area are in a state of close contact and are located in the demolding area. The various molding components of the are in a separated state. Therein, each forming component performs absorbent core forming in the forming area, and performs demolding and transfer of the absorbent core in the demolding area....

Embodiment 2

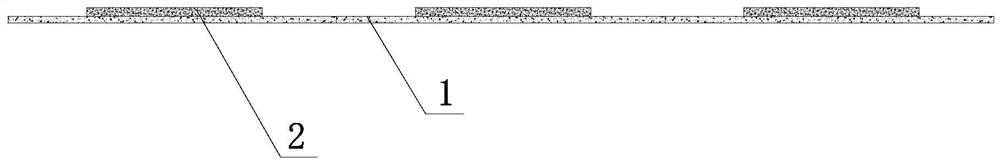

[0040] This embodiment is a molding method of an absorbent core, and the molding method and molding equipment described in Example 1 are applied to the molding of adult diapers, mainly for molding the upper layer of the absorbent core. The specific process is as follows :

[0041] The main component of the upper layer core is composed of a mixture of fibers for water absorption and polymer materials. The two ends of the velvet collecting bin are respectively connected with the defibrating machine and the forming drum, and the fibers are continuously conveyed to the forming drum. After the molecular materials are mixed in the lint collecting bin, they are collected in the tire mold on the surface of the forming drum under the traction of the air flow. This is the same as the prior art.

[0042] However, in this embodiment, the lint collecting bin and the forming drum are only communicated within the range of the forming area, and are not connected in other areas, and the rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com